— January 10th, 2022

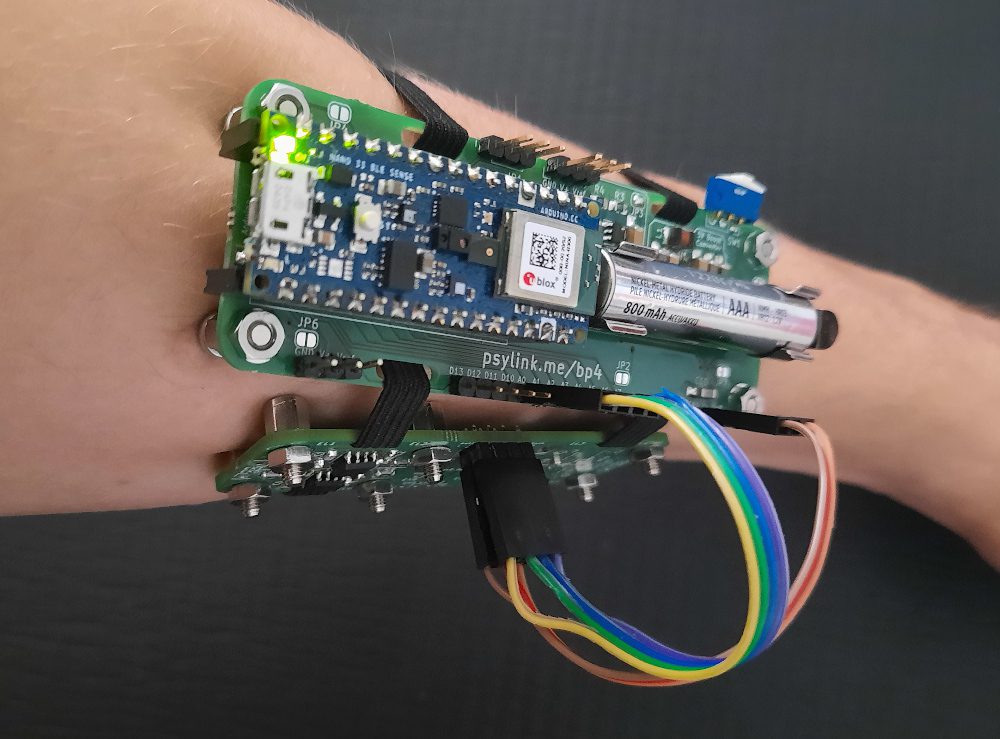

Non-invasive EMG interfaces have the potential to solve many problems that afflict those who suffer from a disability or simply want a more efficient way to perform a task. This is what led one maker, who goes by the name “Hut,” to create their own open source device called PsyLink. It works by measuring the minute electrical impulses that cause muscles to contract and then sending them for further processing and inferencing via a machine learning model.

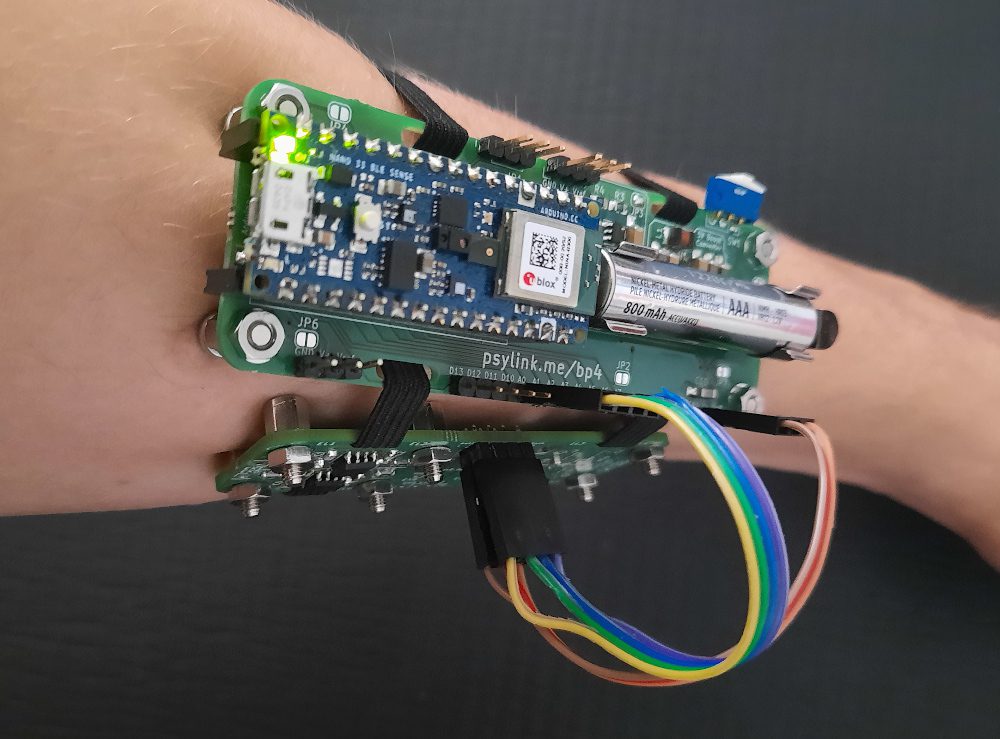

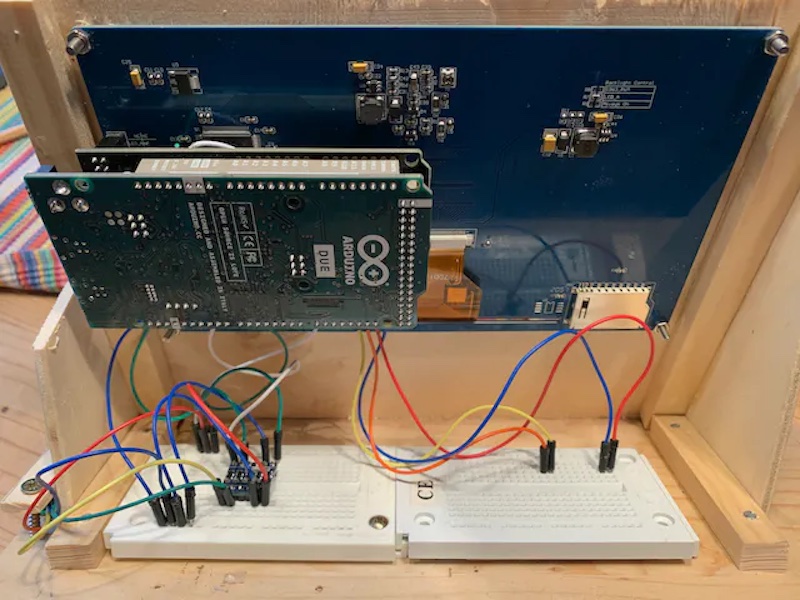

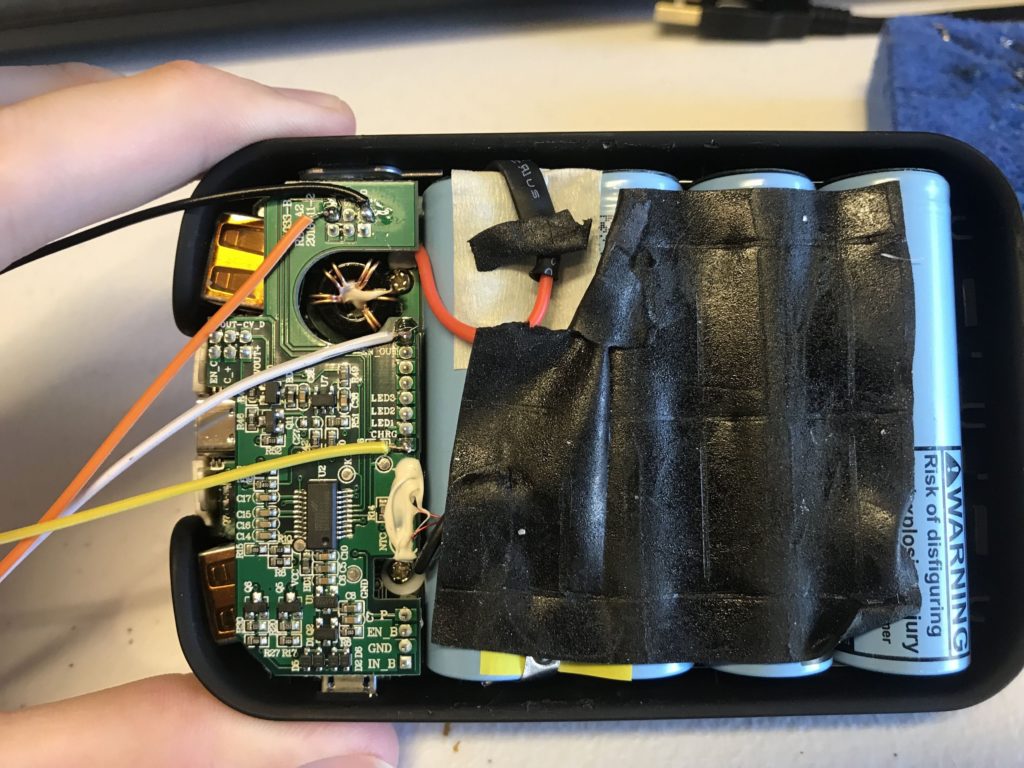

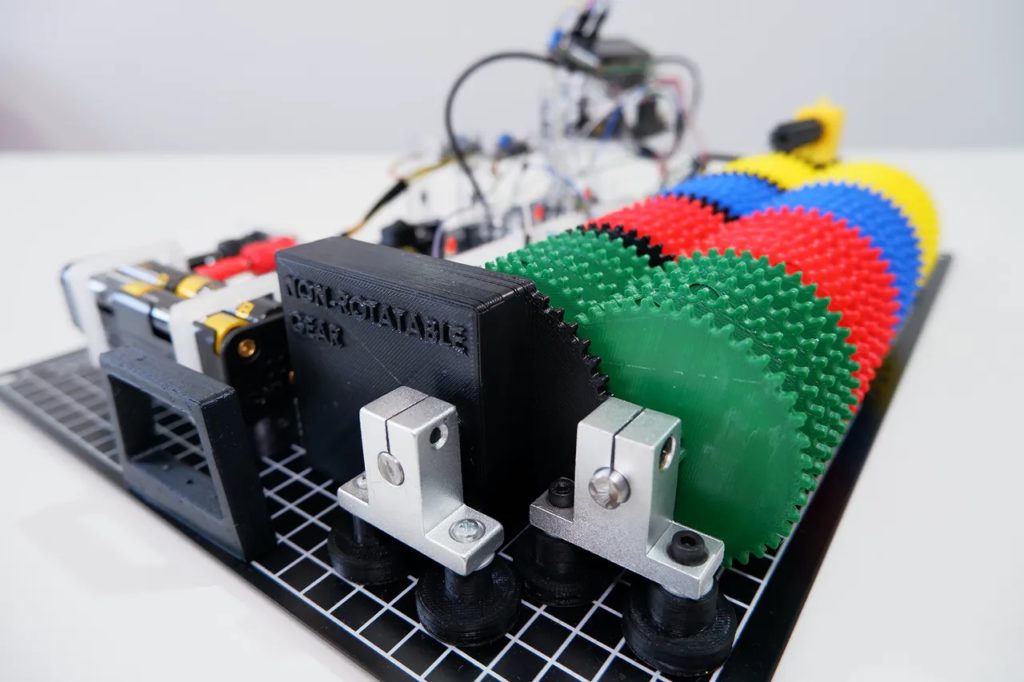

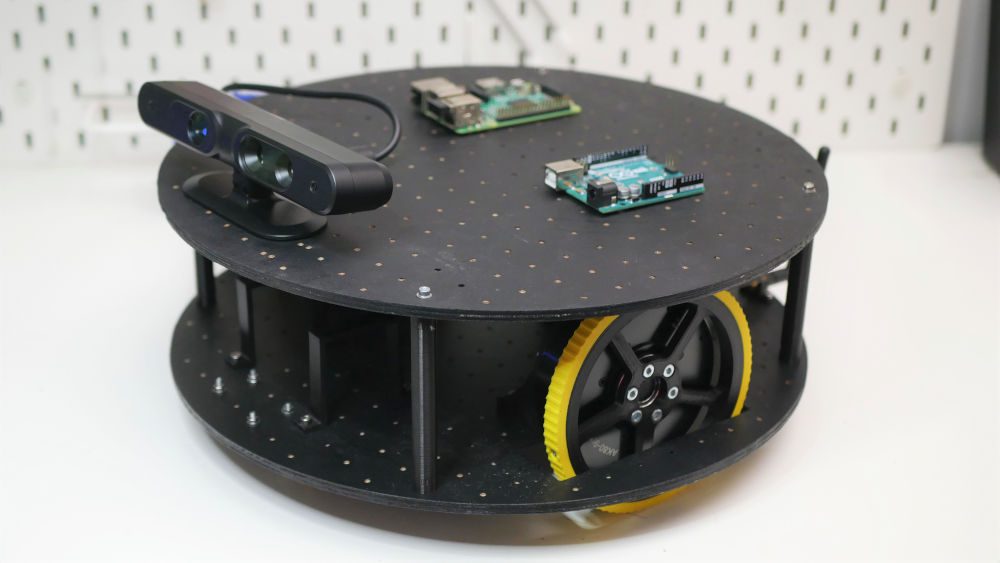

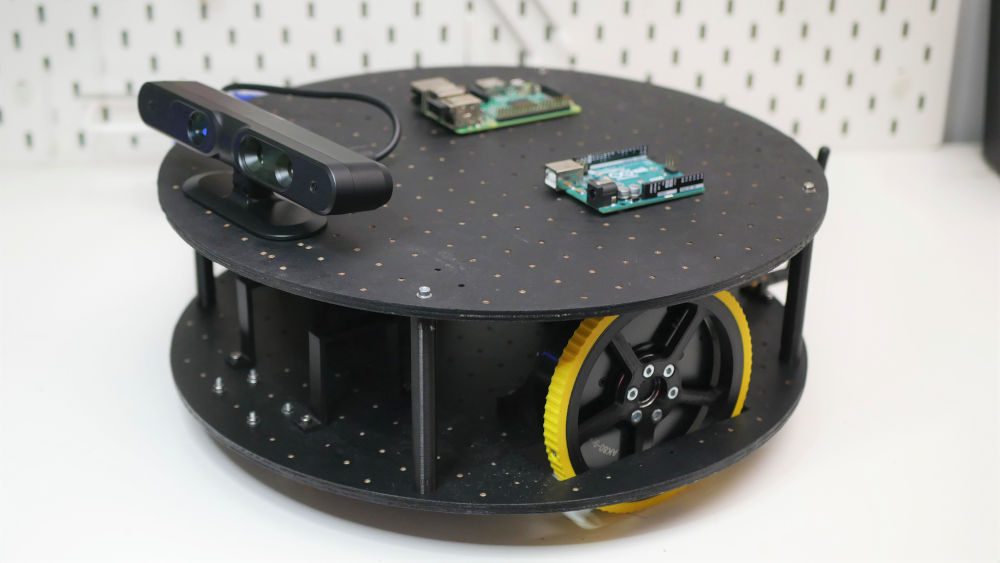

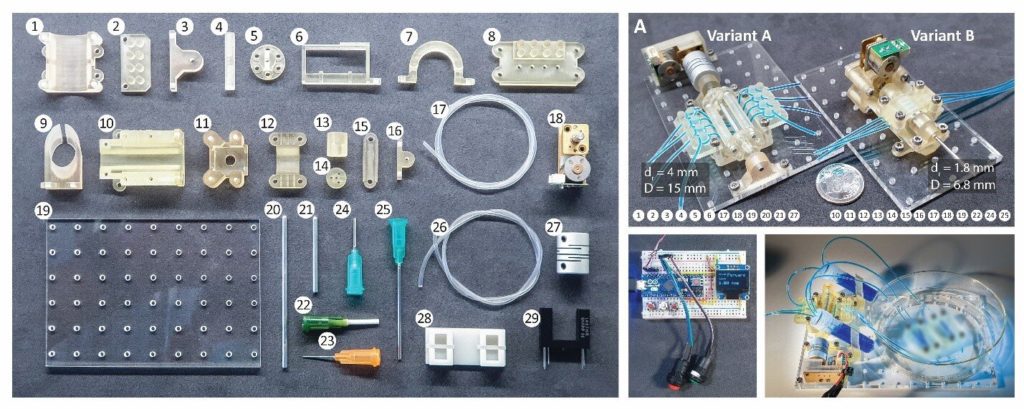

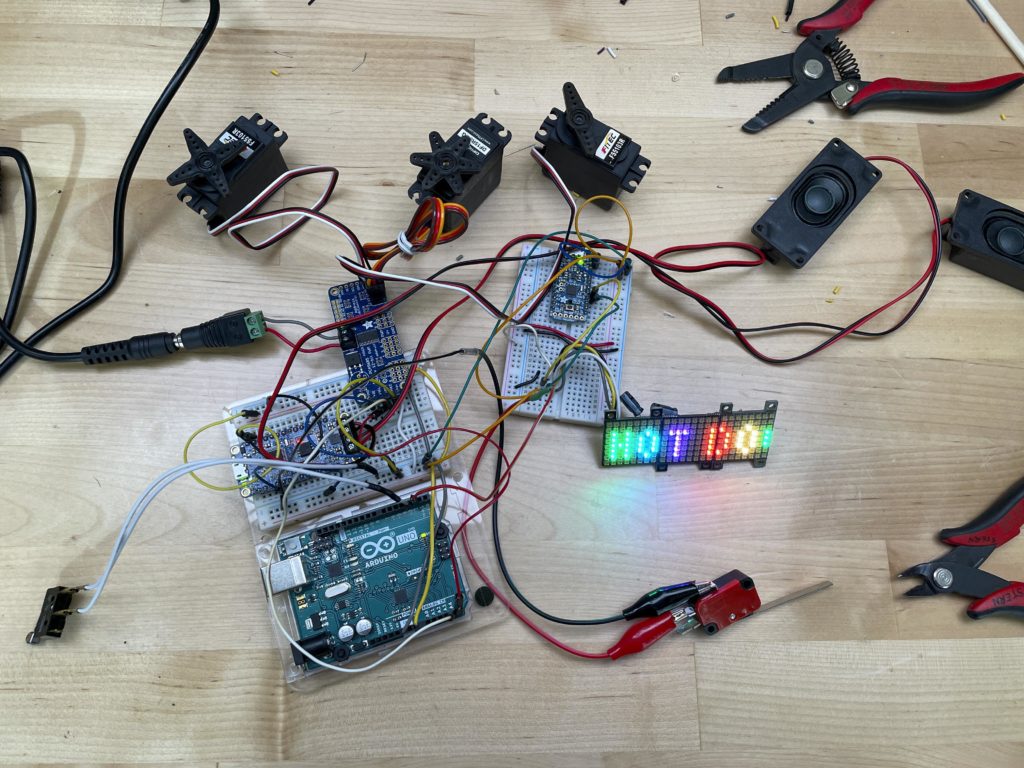

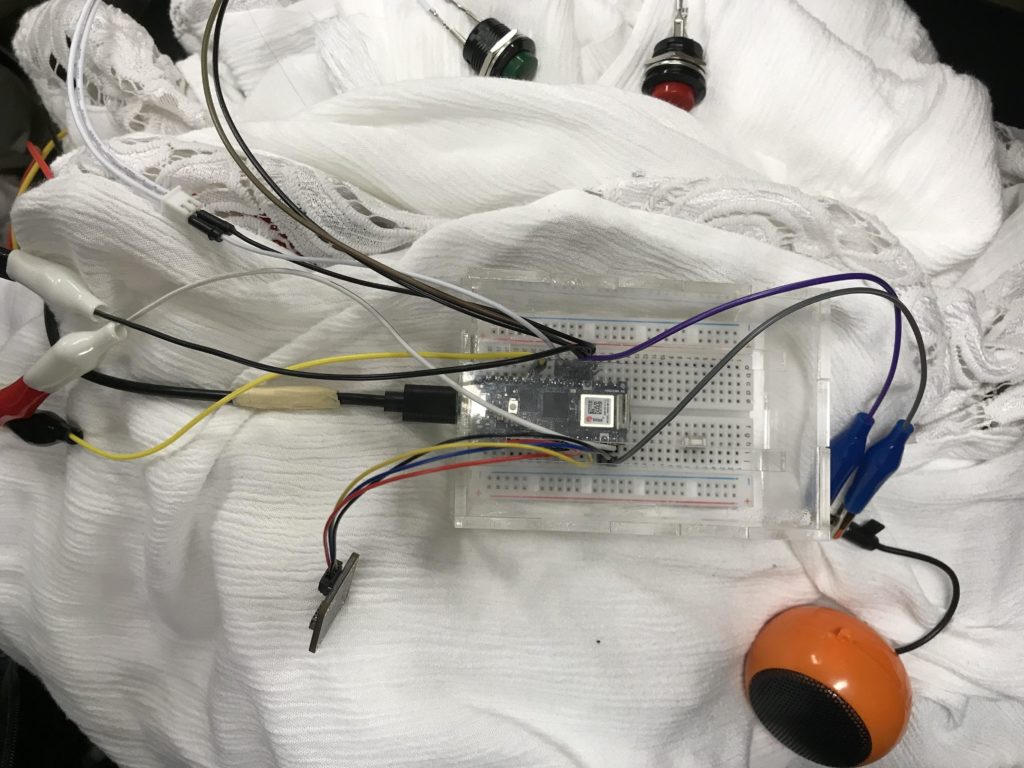

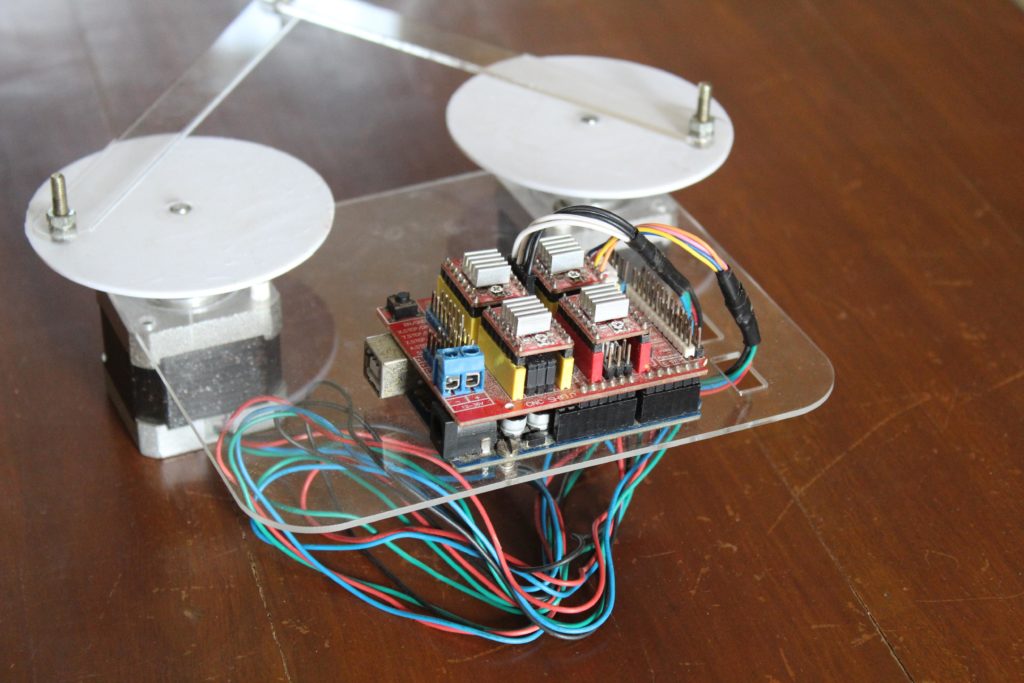

PsyLink’s initial prototype was based around the Nano 33 BLE Sense due to its large number of ADC pins and potential for Bluetooth connectivity. The device features a pair of aluminum foil pads attached to some wires, although this was later changed out for studs embedded within a more secure sleeve. Signals are read from the electrodes and sent through a series of filters made from op-amps and eventually to an analog multiplexer. After that, the signal is digitized by the onboard ADC and transmitted over Bluetooth Low Energy where it is then displayed in a custom desktop application.

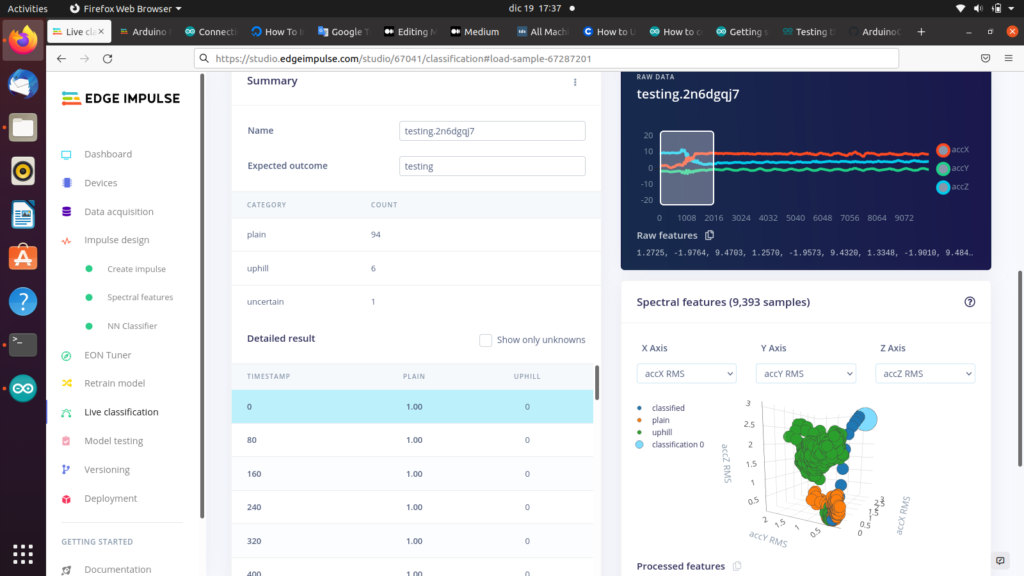

Hut used TensorFlow Lite to take many samples of data and train a neural network to recognize when a certain kind of signal corresponded to a given keypress. Once training was complete, this model could be deployed and used to do everything from typing faster and performing shortcuts, to even playing a video game.

You can read more about this impressive project here on a well-detailed blog for the PsyLink.

Website: LINK