Schlagwort: tech

-

This machine lets you practice baseball solo, similar to Topgolf

Reading Time: 2 minutesTopgolf has a pretty brilliant business model: let golfers do the fun stuff (driving balls at max power), without any of the complications, time commitments, or logistics of running through a full 18-hole course. Batting cages exist to do something similar for baseball, but Pete LeMaster didn’t want to practice batting —…

-

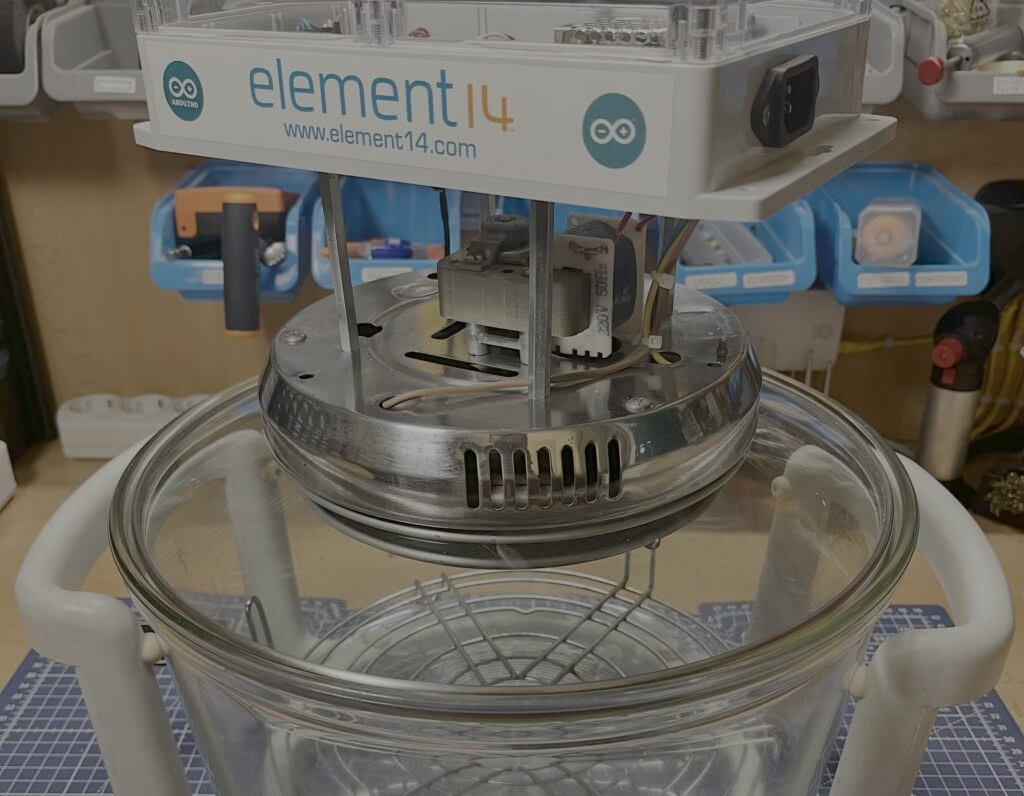

Convert a cheap air fryer into a high-performance 3D printer filament dryer

Reading Time: 2 minutesPost about a 3D printing problem — any 3D printing problem — online and all the top comments will be: “Is your filament dry?” That is a prudent question to ask, because filament that has absorbed moisture will wreak havoc on print quality and can even cause total print failure. If you…

-

Tech-infused high fashion meets insectile aesthetic

Reading Time: 2 minutesIn the world of FashionTech — a field that blends haute couture design and mechatronics engineering — nobody has more experience than Anouk Wipprecht. Her own creations are always intriguing, but she also mentors students to help them realize their own visions. As part of a collaboration between Summa Fashion and Fontys…

-

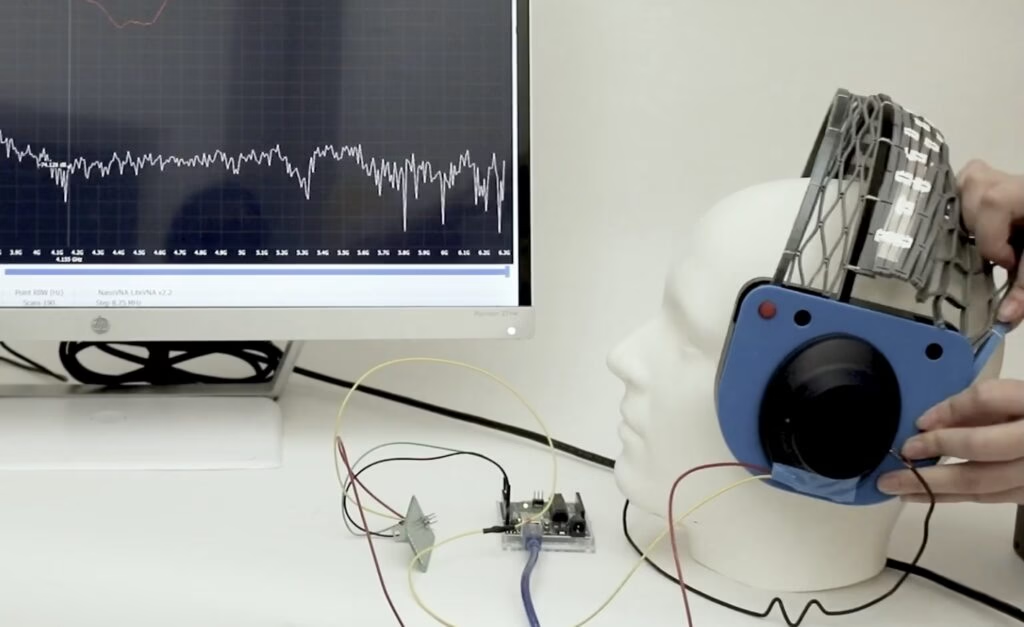

James Bruton steers homemade car with his face

Reading Time: 2 minutesThe Arduino UNO Q is here and it is a very exciting product that combines a Qualcomm Dragonwing QRB2210 processor and STM32U585 microcontroller, giving users the best of both worlds in a single convenient package. One of its best features is the ability of the SBC to send data seamlessly to the…

-

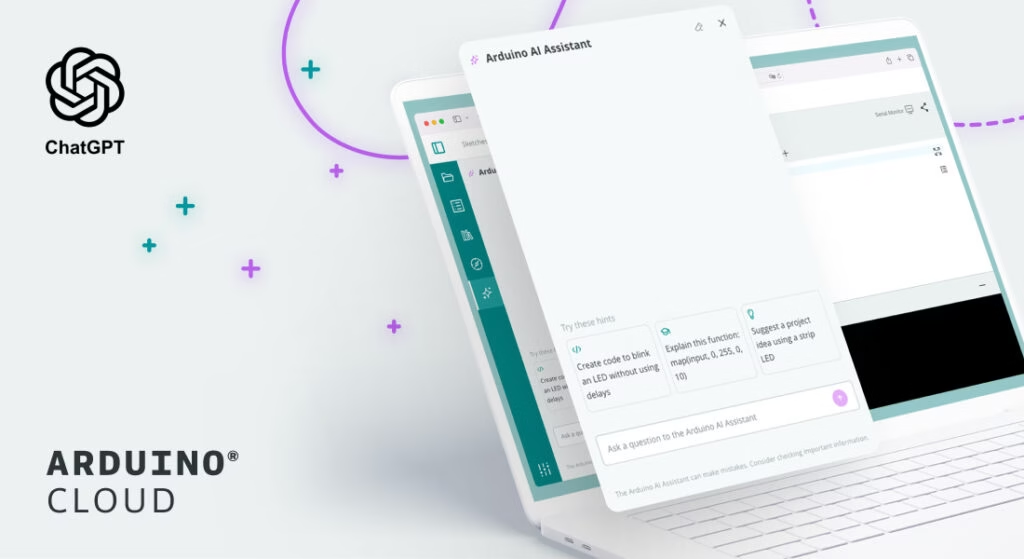

Arduino AI Assistant vs. ChatGPT: Which one to use for your projects?

Reading Time: 4 minutesIf you’ve been turning to ChatGPT to write your Arduino code, you may actually be missing out on a tool designed just for you: the Arduino AI Assistant, built directly into Arduino Cloud. While general-purpose AIs like ChatGPT can generate code, they often miss critical details, such as using the wrong libraries…

-

Meet Arduino – and UNO Q! – at Maker Faire Rome

Reading Time: 3 minutesFrom October 17th to 19th, the Gazometro Ostiense in Rome will once again become a playground for innovation as Maker Faire Rome returns to celebrate the brilliant minds turning ideas into reality. As a Gold Partner, we’ll be there with our biggest booth ever in Hall 41, bringing together people, projects, and…

-

This wild haptic system can be used to build vehicles

Reading Time: 2 minutesAs virtual reality (VR) and mixed reality (MR) slowly grow in adoption, their shortcomings become more obvious. Most glaringly, they only engage users’ sense of sight and hearing. Haptic tactile feedback is almost non-existent and so picking up a “sword” in VR feels like picking up a VR controller, because that’s what…

-

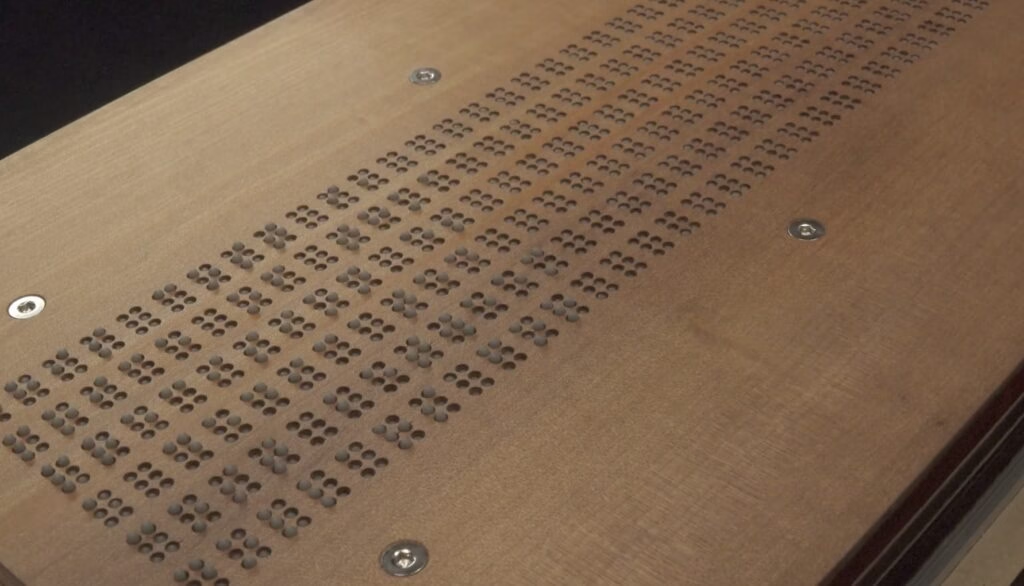

Novel mechanism makes refreshable braille displays practical

Reading Time: 2 minutesTactile displays — particularly for use as refreshable braille displays — have always been a challenge to design and fabricate, as they require so many moving parts. Every dot needs its own actuated mechanism and there needs to be dozens or hundreds of dots squeezed into a small space. Conventional micro actuators…

-

SoilTile turns earth into an oversized touchpad

Reading Time: 2 minutesWe’re used to interacting with electronic technology that is cold, rigid, and overwhelmingly artificial. The device you’re reading this on doesn’t resemble anything found in nature and, consciously or not, you see it as something separate from the natural world. But what if the dividing boundary was less distinct? How would that…

-

A new chapter for Arduino – with Qualcomm, UNO Q, and you!

Reading Time: 3 minutesToday we’re sharing some truly exciting news: Arduino has entered into an agreement to join the Qualcomm Technologies, Inc. family! This is a huge step in our journey – one that allows us to keep growing, thriving, and making technology accessible to everyone, while bringing our values of openness, simplicity, and community…

-

This Arduino Nano R4-controlled hourglass simulates sand with LEDs

Reading Time: 2 minutesOutside of playing board games, hourglasses are almost entirely pointless these days. And yet, they’re still incredibly satisfying. Watching the sand fall in a steady and consistent stream is downright mesmerizing. Sadly, you probably can’t make your own hourglass unless you happen to be very skilled at glassblowing. But you can create…

-

This chest contains the beating heart of Davy Jones

Reading Time: 2 minutesThe Pirates of the Caribbean film franchise really likes to make figurative elements and metaphors quite literal, as shown in Dead Man’s Chest when the chest in question is shown to contain the actual beating heart of Davy Jones. That’s a fun visual that Grendel Studios’ Erik Finley turned into a real-life…

-

Gathering weather telemetry with a Nano 33 BLE Sense payload

Reading Time: 2 minutesMost model rockets don’t do anything practical — they just go up really fast and then come back down more slowly to land in a field somewhere. Those launches can still be a lot of fun to watch, but they aren’t exactly useful. However, the sky has plenty of data of worth…

-

This mint tin radio is a fresh take on emergency communication

Reading Time: 2 minutesMost of us get our news via the internet these days, which is only natural given the convenience and availability. But during an emergency, such as weather extreme enough to cause power or network outages, the internet may be inaccessible. How do you learn vital information in that scenario? The answer is…

-

Introducing a new Bluetooth provisioning flow — With the UNO R4 WiFi

Reading Time: 2 minutesWe’re excited to roll out a new Bluetooth provisioning flow on Arduino Cloud — and the UNO R4 WiFi is the first board to support it! Say goodbye to cables and complicated steps: setup is now faster and smoother. Wait, what is provisioning? Provisioning is the process of securely registering your Arduino…

-

Building a DIY GPU with Arduino

Reading Time: 2 minutesA GPU (graphics processing unit) is a specialized computer component for, primarily, rendering graphics. That RTX 5090 that you took out a second mortgage to buy is one example. But GPUs are useful for far more than just playing the newest games at max settings; their parallel processing capabilities make them desirable…

-

This robot picks locks using brains instead of brawn

Reading Time: 2 minutesA physical lock, like what secures your front door, has a finite and calculable number of combinations, just like a digital keypad does. There are a set number of pins in the lock and each can be one of a set number of lengths. Each of those numbers varies based on manufacturer…

-

Dive into satellite IoT with the new Arduino-compatible Iridium Certus 9704 Development Kit

Reading Time: 3 minutesIoT (Internet of Things) devices can be very useful, but they do, by definition, require internet access. That’s easy enough when Wi-Fi® is available, and it is even possible to rely on LoRa® and cellular data connections to transmit data outside of urban areas. However, deploying an IoT device to a truly…

-

Alvik Fight Club: A creative twist on coding, competition, and collaboration

Reading Time: 3 minutesWhat happens when you hand an educational robot to a group of developers and ask them to build something fun? At Arduino, you get a multiplayer robot showdown that’s part battle, part programming lesson, and entirely Alvik. The idea for Alvik Fight Club first came to life during one of our internal…

-

Concept Bytes’ coffee table tracks people and walks itself across a room when called

Reading Time: 2 minutesThe term “mmWave” refers to radio waves with wavelengths on the millimeter scale. When it comes to wireless communications technology, like 5G, mmWave allows for very fast data transfer — though that comes at the expense of range. But mmWave technology also has some very useful sensing and scanning applications, which you…

-

Building a Wi-Fi robot controller that accepts voice commands

Reading Time: 2 minutesThe whole point of a robot is that it can operate without direct control input from an operator. Except there are many exceptions and it isn’t uncommon for roboticists and operators to require direct control. The Tinkering Techie needed to add that capability to his rover robot and built his own Wi-Fi…