Schlagwort: tachometer

-

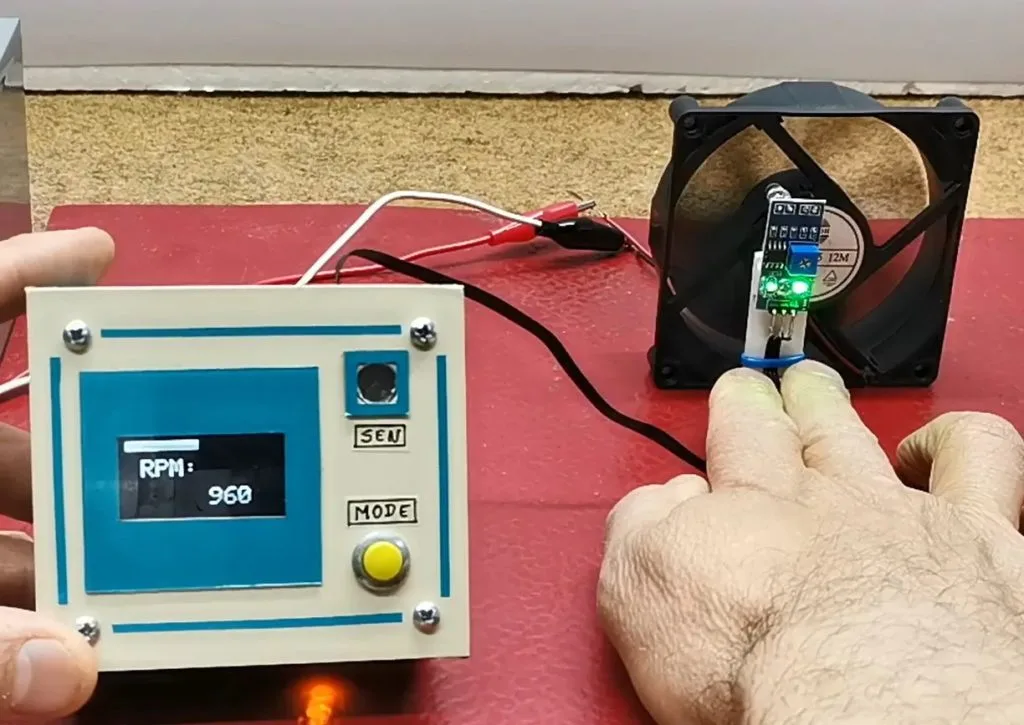

Build your own tachometer with an IR sensor and an Arduino

Reading Time: 2 minutesA tachometer is a device that display the speed of a rotating object. The most well-known example is the automotive tachometer, which shows a driver the RPM of the engine — information that is particularly useful when the car has a manual transmission. But there are many other uses for tachometers and…

-

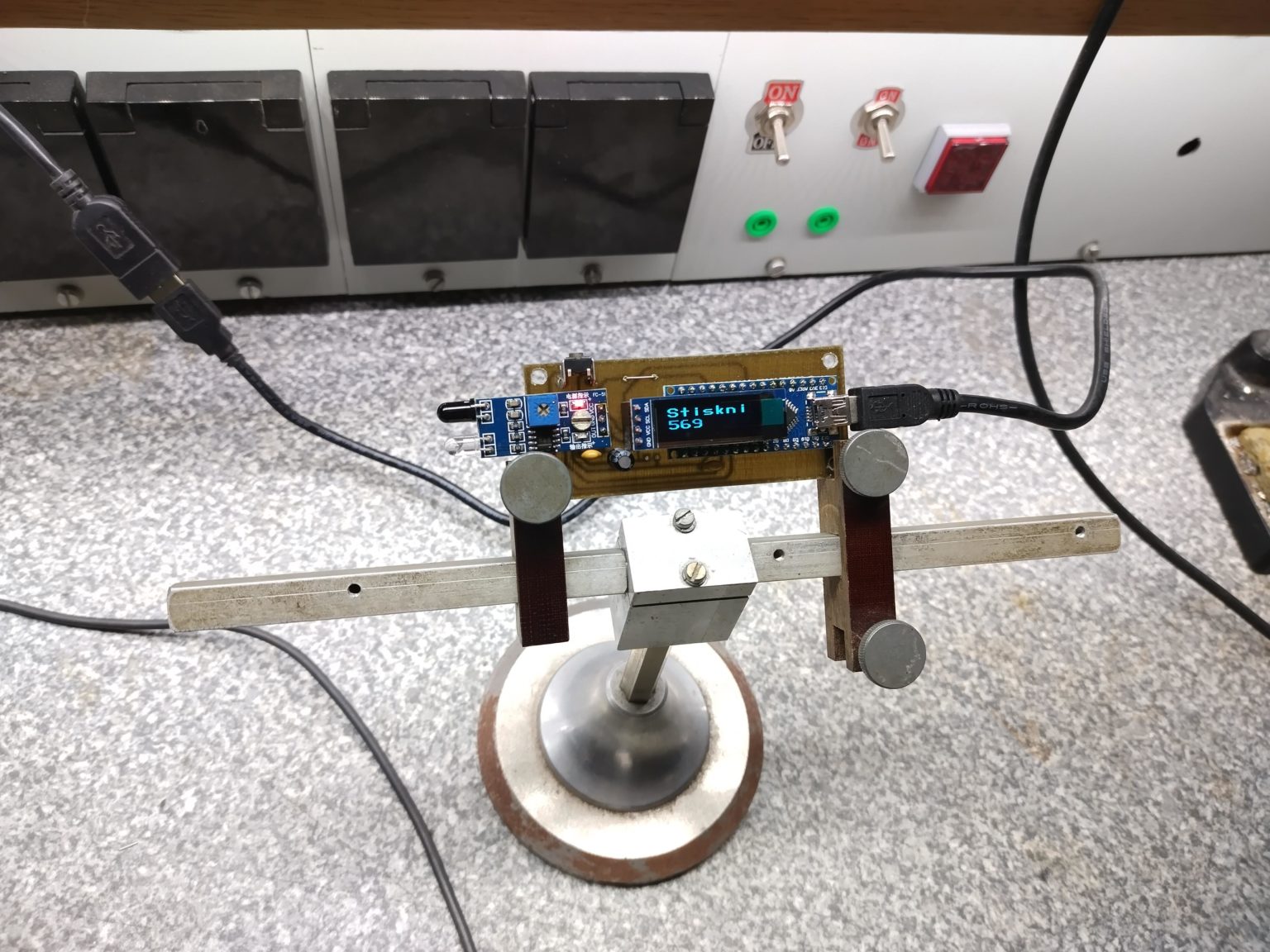

A DIY non-contact digital tachometer for machinists

Reading Time: 3 minutesA tachometer is a device that counts the revolutions of a rotating object, with the most well-known example being the automotive tachometer that monitors the revolutions per minute (RPMs) of an internal combustion engine. But tachometers are useful, and sometimes a requirement, in many other applications. RPM is a very important datum…