Schlagwort: smart industry

-

Sustainable transformation of agriculture with the Internet of Things

Reading Time: 3 minutesWith the urgency to prevent environmental degradation, reduce waste and increase profitability, farmers around the globe are increasingly opting for more efficient crop management solutions supported by optimization and controlling technologies derived from the Industrial Internet of Things (IIoT). Intelligent information and communication technologies (IICT) (machine Learning (ML), AI, IoT, cloud-based analytics,…

-

Engineer’s guide to Industrial IoT in Industry 4.0

Reading Time: 5 minutesThis is an edited version of a longer piece first published on Wevolver. In recent years, industrial enterprises are accelerating their digital transformation and preparing themselves for the fourth industrial revolution (Industry 4.0). This digitization of production processes enables industrial organizations to implement agile and responsive manufacturing workflows, which rely on flexible…

-

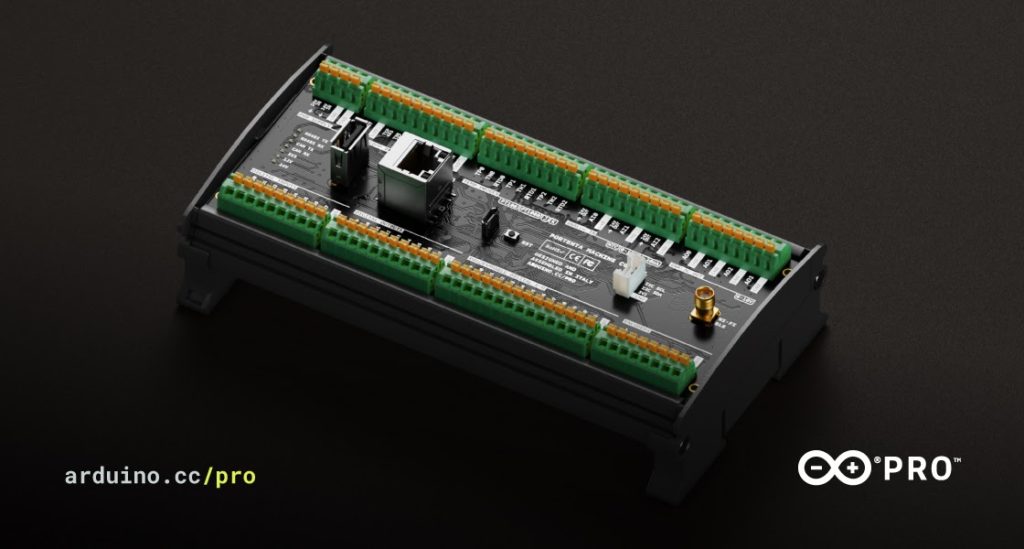

Portenta Machine Control: Add a powerful brain to your machines

Reading Time: 3 minutesArduino Pro is introducing a powerful new member of the Portenta product family, the Portenta Machine Control. It’s a fully-centralized, low-power, industrial control unit able to drive equipment and machinery. Plus, you can program it using the Arduino framework or other embedded development platforms. [youtube https://www.youtube.com/watch?v=2wrBy8qNT60?feature=oembed&w=500&h=281] Thanks to its computing power, the…