Schlagwort: SLA 3D Printer

-

Formlabs Form 2 Review – Best Resin 3D Printer of Fall 2018

Reading Time: 12 minutesThe Formlabs Form 2 is our pick for the “Best Resin 3D Printer of Fall 2018”. Check out our Formlabs Form 2 review to find out why. When it comes to 3D printing, FDM printers take all the glory; Ultimakers, Prusas, and Crealitys are talked about constantly. Their machines offer makers, hobbyists,…

-

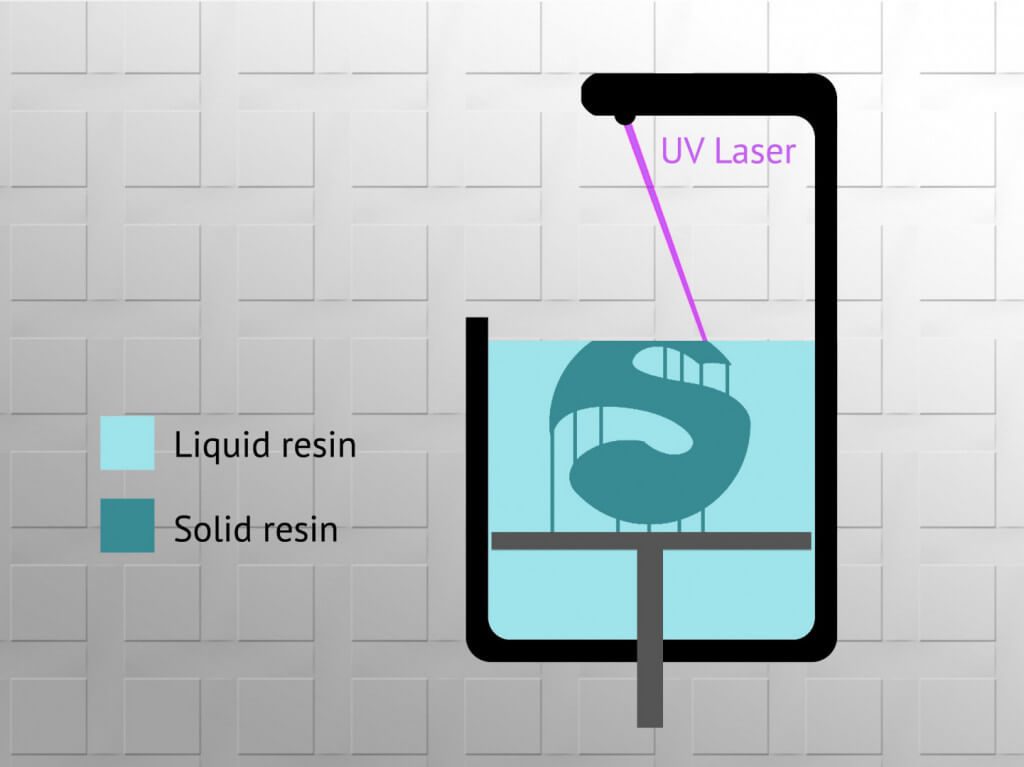

An auto-curing chamber for SLA prints

Reading Time: 2 minutesAn auto-curing chamber for SLA prints Arduino Team — July 3rd, 2018 If you have a 3D printer, it’s probably the fused deposition modeling (FDM) type that deposits melted material onto a bed, eventually building up whatever you had in mind. Stereolithography (SLA) printers, however, work in the opposite way using light…

-

![[DEAL] Peopoly Moai Fully Assembled SLA 3D Printer, $300 Off at $1,695](data:image/svg+xml;charset=utf-8,%3Csvg xmlns%3D'http%3A%2F%2Fwww.w3.org%2F2000%2Fsvg' viewBox%3D'0 0 854 480'%2F%3E)

[DEAL] Peopoly Moai Fully Assembled SLA 3D Printer, $300 Off at $1,695

Reading Time: 2 minutesMatterHackers is casting the wonderful world of SLA under its 3D printer spotlight this week, knocking $300 off the price of a fully assembled Peopoly Moai. After a successful Kickstarter campaign and launch to market Peopoly’s Moai SLA 3D printer kit can now be found churning out highly detailed prints across the…

-

20 Best Resin (SLA/DLP) 3D Printers 2017 / 2018

Reading Time: 3 minutesWhen it comes to 3D printer sales, stereolithography (SLA) definitely trails behind fused deposition modeling (FDM). But in terms of quality, you’ll find that an SLA 3D printer is usually the way to go. If you choose an SLA 3D printer, you usually don‘t go for big builds, but for quality and highly…

-

Beginner’s Guide on How to Buy a 3D Printer

Reading Time: 5 minutesSo you want to buy a 3D printer? Read this guide before you go shopping to get the best printer for your needs and your budget. You’ve heard so many great things about 3D printers and what you can do with them. There are so many wonderful machines which can make your…

![[DEAL] Peopoly Moai Fully Assembled SLA 3D Printer, $300 Off at $1,695](https://www.blogdot.tv/wp-content/uploads/2018/03/deal-peopoly-moai-fully-assembled-sla-3d-printer-300-off-at-1695.jpg)