Schlagwort: robots

-

EduExo Pro is an Arduino-controlled robotic exoskeleton kit that’s now on Kickstarter

Reading Time: 2 minutesEduExo Pro is an Arduino-controlled robotic exoskeleton kit that’s now on Kickstarter Arduino Team — June 29th, 2021 Admit it, you have dreamed of wearing something like Tony Stark’s Iron Man suit. Sadly, that technology is fictional and real world exoskeleton suits are expensive. But a Swiss company called Auxivo wants to…

-

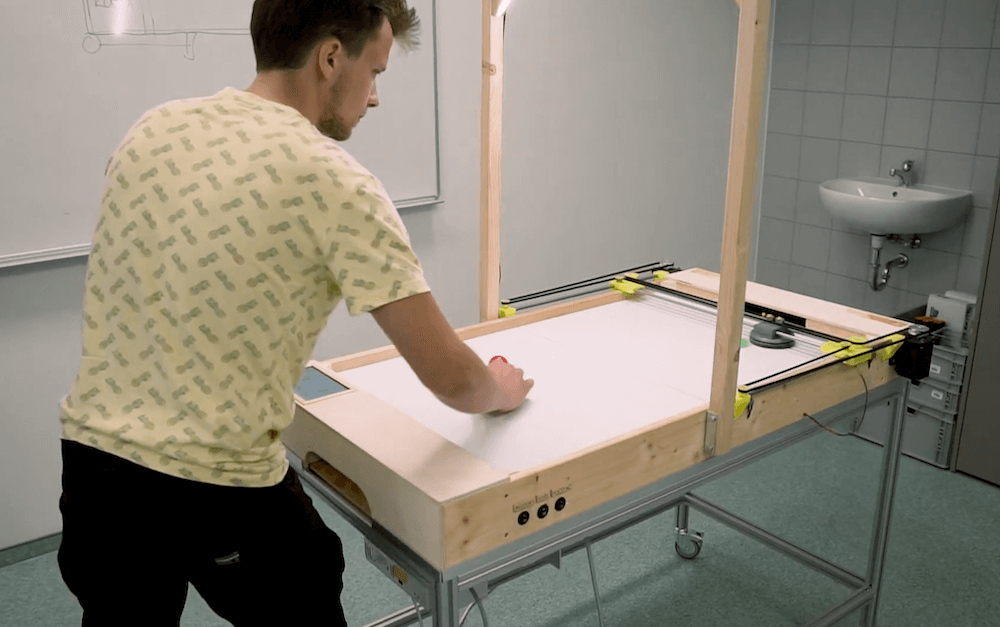

Meet Simone Giertz: Inventor, robotics enthusiast, and YouTuber

Reading Time: 13 minutesEven if you don’t follow Simone Giertz on social media or YouTube, there’s a good chance you know of her work. Originally hailed as the Queen of Shitty Robots, Simone’s early videos of questionable contraptions, such as the Toothbrush Machine and Hair Washing Robot, quickly went viral, birthing a variety of GIFs…

-

This archery robot always hits the target

Reading Time: 2 minutesArduino Team — June 14th, 2021 Both archery and robotics are extremely fun, but what happens when you combine the two? In Kamal Carter’s case, he constructed his own autonomous robotic archery system that can not only acquire and aim at targets, but even draw back the bow and fire an arrow all on its own.…

-

DIY Perseverance rover replica looks and moves like NASA’s

Reading Time: 2 minutesDIY Perseverance rover replica looks and moves like NASA’s Arduino Team — June 7th, 2021 Merely looking at the latest Mars rover, Perseverance, will make almost any nerd giddy with excitement over the amount of cool tech that’s crammed into the vehicle before it gets shot into space. This feeling is what…

-

James Bruton’s robot uses three ball-shaped wheels to move in any direction

Reading Time: 2 minutesJames Bruton’s robot uses three ball-shaped wheels to move in any direction Arduino Team — June 5th, 2021 Wheeled robots normally have wheels that move in a single axis and steer by using either differential speeds or by pivoting some kind of guide wheel. However, this leads to some drawbacks, the most…

-

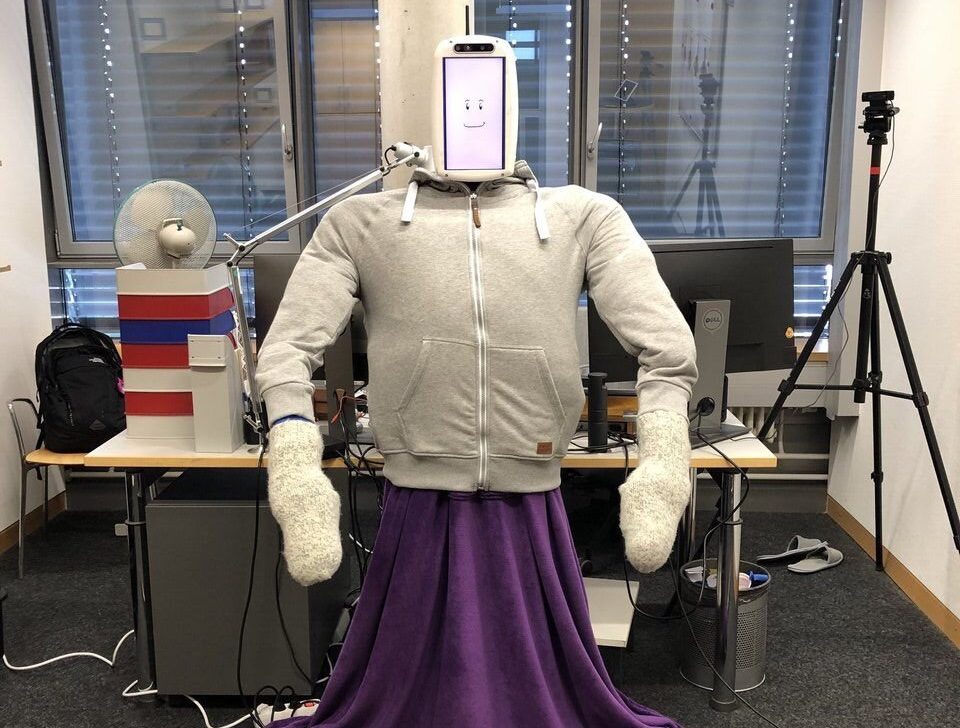

Say hi to HuggieBot 2.0, a robot that knows when to hug and when to let go

Reading Time: < 1 minuteSay hi to HuggieBot 2.0, a robot that knows when to hug and when to let go Arduino Team — February 16th, 2021 Do you need a hug? Are friends and family not around? As seen here, researchers from the Max Planck Institute for Intelligent Systems (MPI-IS) and ETH Zürich may have…

-

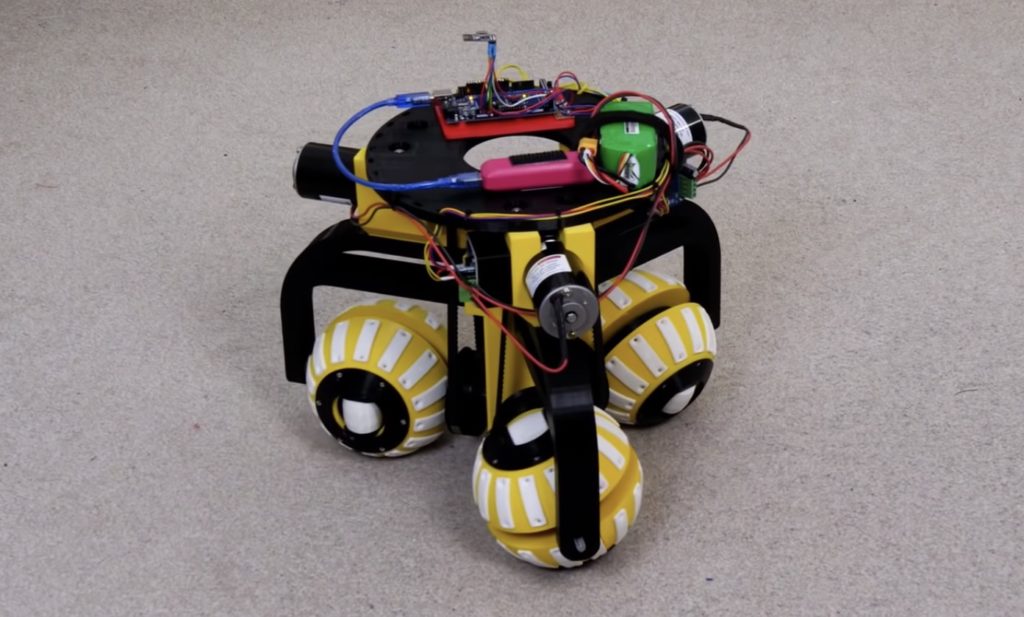

3D-printed mobile robot platform based on the Arduino Due

Reading Time: 2 minutes3D-printed mobile robot platform based on the Arduino Due Arduino Team — January 19th, 2021 Although an Arduino can be a great way to provide computing power for a mobile robot platform, you’ll need a variety of other electronics and mechanical components to get it going. In his write-up, computer science student Niels…

-

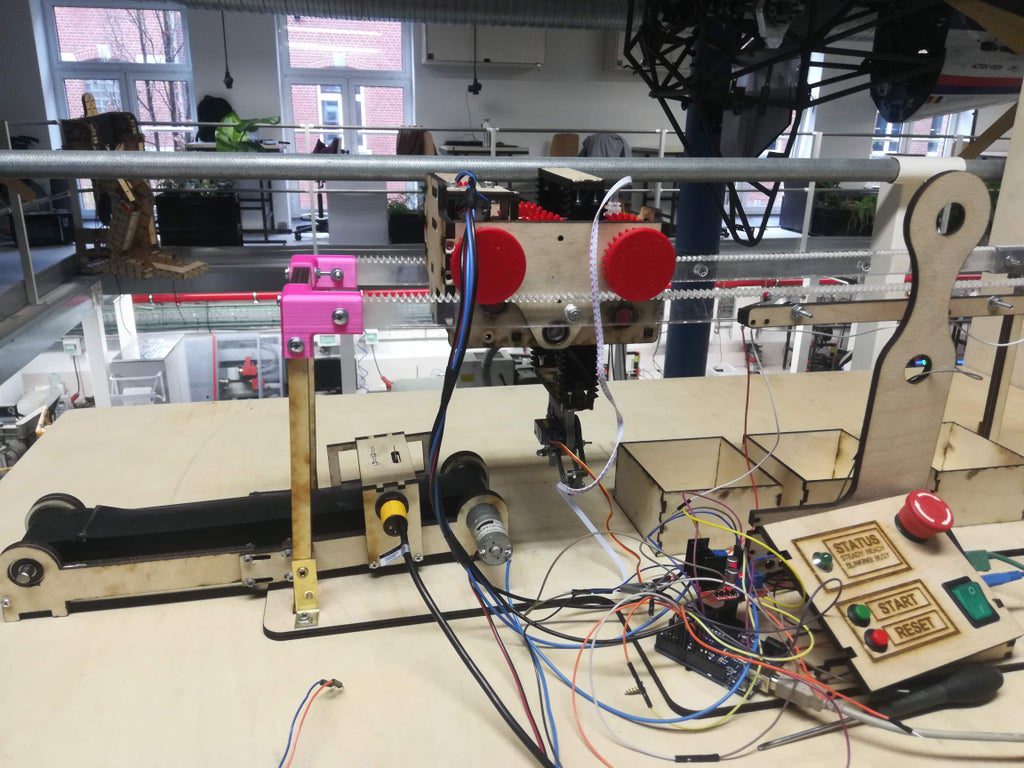

Let this robotic system sort your LEGO bricks for you

Reading Time: 2 minutesIf you don’t enjoy sorting LEGO, you will be pleased to know that students at Bruface – or the Brussels Faculty of Engineering in Belgium – are working on an automated machine to do it for you! The team’s prototype device detects brick colors on a conveyor belt and picks them up…

-

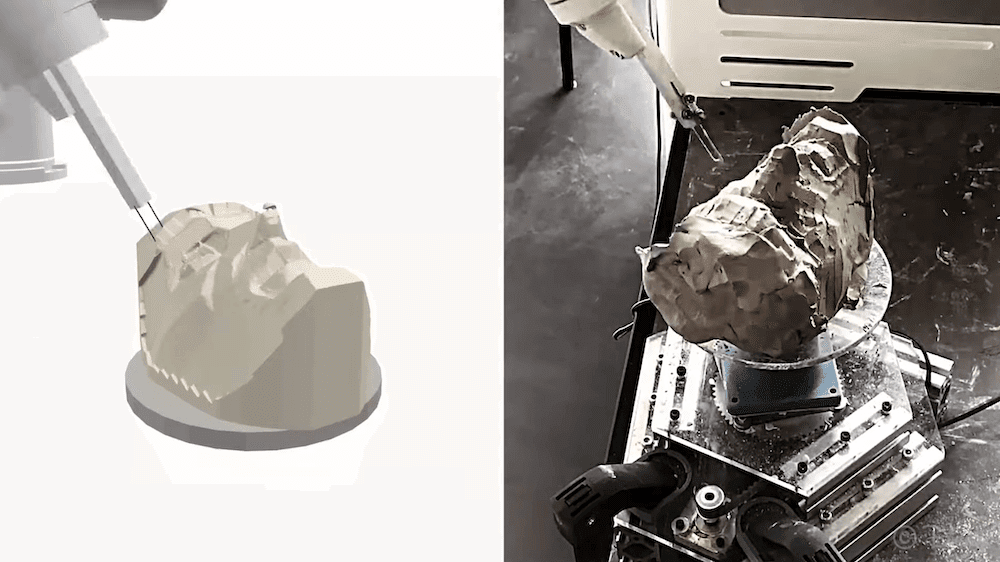

RobotSculptor uses a six-axis robot arm to sculpt clay models

Reading Time: < 1 minuteRobotSculptor uses a six-axis robot arm to sculpt clay models Arduino Team — December 3rd, 2020 Robotic fabrication techniques such as 3D printing enable you to make a copy of a wide variety of items. Actually sculpting something out of clay, however, remains a largely human pursuit. One might also miss…

-

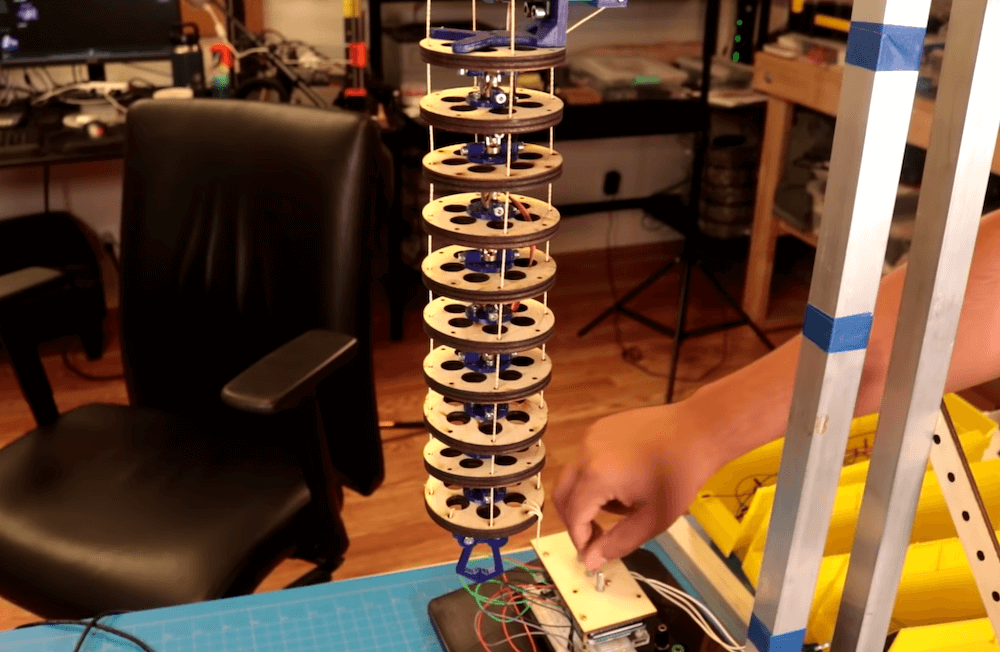

Creating a continuum tentacle-like robot with Arduino

Reading Time: < 1 minuteCreating a continuum tentacle-like robot with Arduino Arduino Team — November 30th, 2020 Continuum robots — which look like a tentacle or perhaps an elephant’s trunk — use a series of linkage sections and internal tendons to move both horizontally and vertically. While they may seem quite exotic, in the video…

-

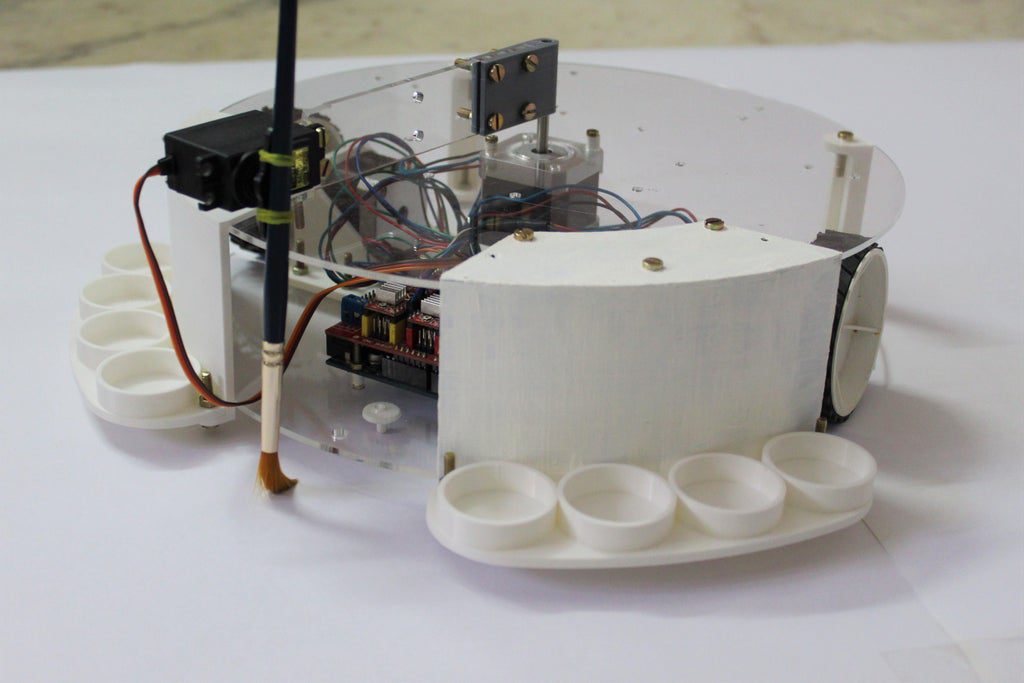

This Arduino-powered robot is like a Roomba with a paintbrush

Reading Time: 2 minutesThis Arduino-powered robot is like a Roomba with a paintbrush Arduino Team — November 16th, 2020 Can robots paint? More specifically, can they create art? The second question is, of course, open for debate, but Technovation’s robotic build shows that they can indeed wield a paintbrush. The device, shaped vaguely like a…

-

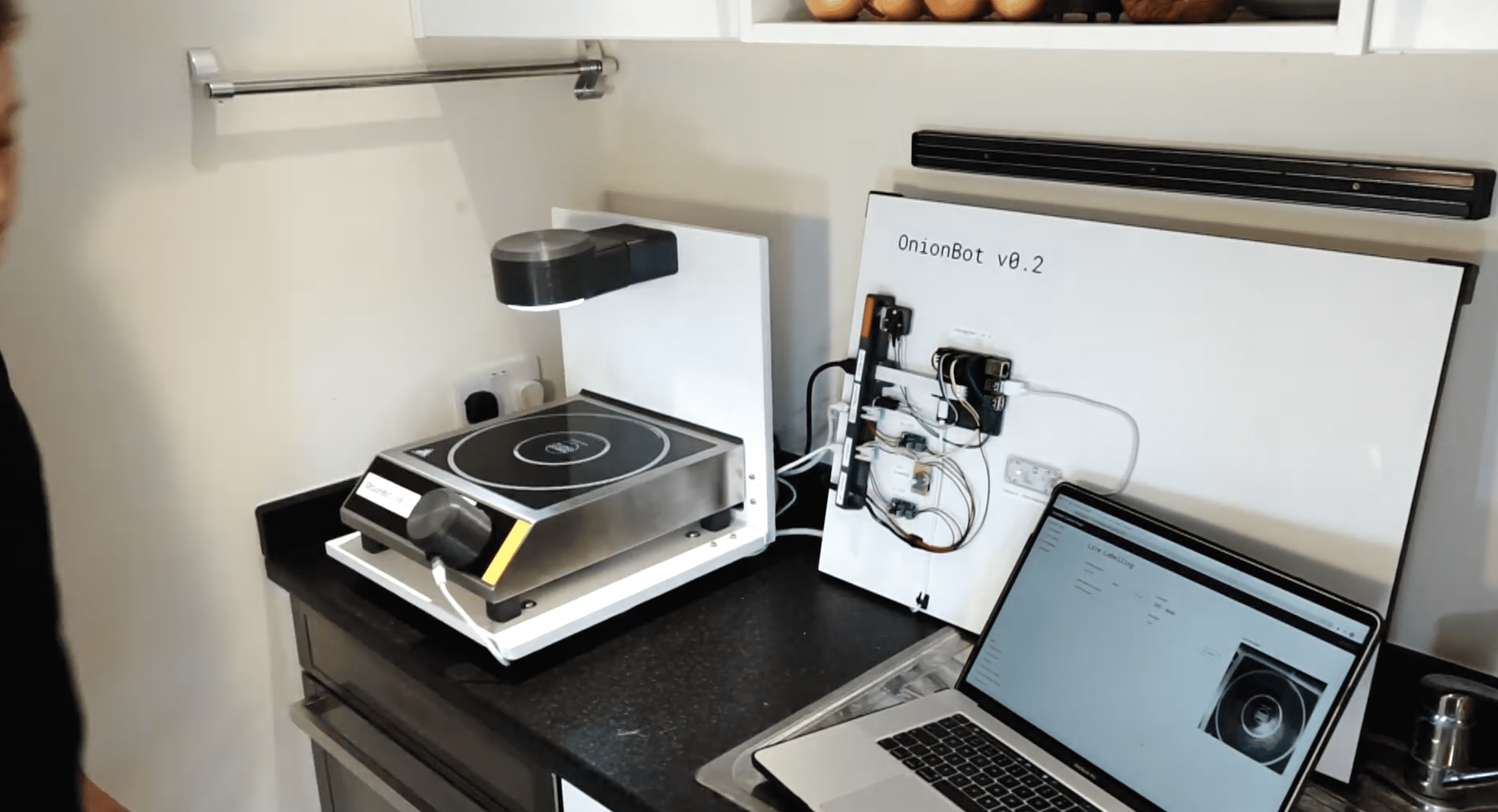

Hire Raspberry Pi as a robot sous-chef in your kitchen

Reading Time: 3 minutesDesign Engineering student Ben Cobley has created a Raspberry Pi–powered sous-chef that automates the easier pan-cooking tasks so the head chef can focus on culinary creativity. [youtube https://www.youtube.com/watch?v=W4utRCyo5C4?feature=oembed&w=500&h=281] Ben named his invention OnionBot, as the idea came to him when looking for an automated way to perfectly soften onions in a pan…

-

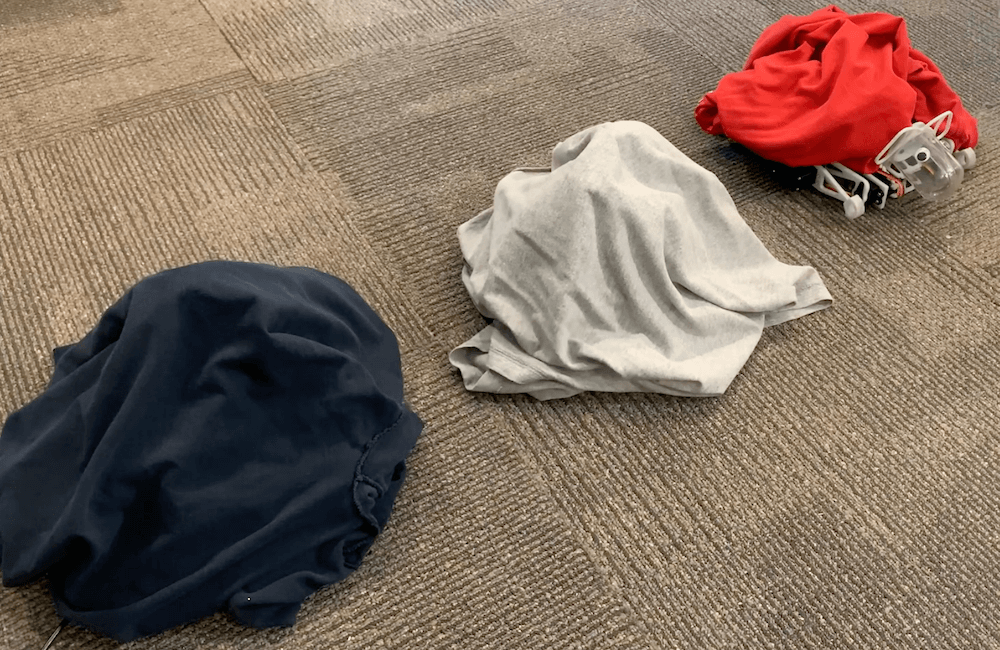

Transform a pile of clothing into the robot of your nightmares

Reading Time: 2 minutesTransform a pile of clothing into the robot of your nightmares Arduino Team — October 26th, 2020 While whatever you heard bump in the night was probably nothing to be concerned about, if you see a suspicious blob of clothing on the floor, you might give it another look. Although not particularly…

-

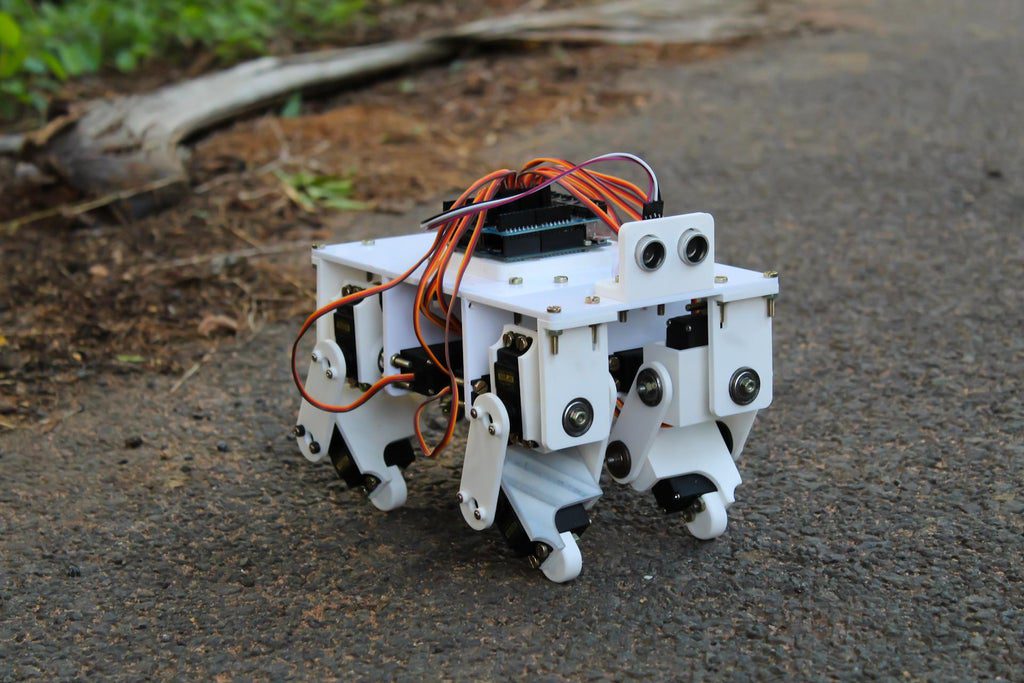

DIY quadruped robot brought to life for under $60

Reading Time: 2 minutesDIY quadruped robot brought to life for under $60 Arduino Team — October 10th, 2020 Animals like dogs, cats, raccoons, rhinoceroses, and many more get around on four legs. To help imitate this natural phenomenon, maker “Technovation” decided to create a low-cost quadruped robot using 12 servo motors and a variety of…

-

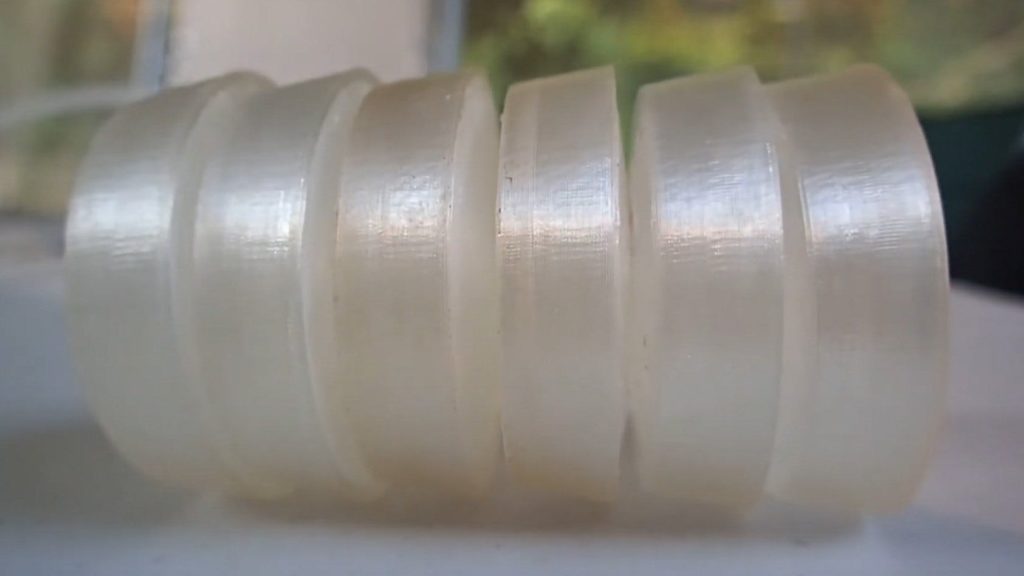

This Arduino-controlled soft robot gets around like an earthworm

Reading Time: < 1 minuteThis Arduino-controlled soft robot gets around like an earthworm Arduino Team — September 28th, 2020 After studying the way a worm wiggles, Nicholas Lauer decided to create his own soft robotic version. What he came up with uses an Arduino Uno for control, inflating six 3D-printed segments sequentially to order to…

-

KAUDA is a low-cost, highly-efficient robotic arm

Reading Time: < 1 minuteKAUDA is a low-cost, highly-efficient robotic arm Arduino Team — September 16th, 2020 Would you like your own industrial robot arm, but don’t have tens of thousands of dollars to spend? You could instead build Giovanni Lerda’s KAUDA, a five-axis device that uses under 800g of PLA, an Arduino Mega, and…

-

Say hi to Sourino, a robotic mouse for kitties (and kiddos)

Reading Time: < 1 minuteSay hi to Sourino, a robotic mouse for kitties (and kiddos) Arduino Team — September 2nd, 2020 Sourino — which comes from the French word for mouse, “souris,” plus Arduino — is a small robot by 11-year-old maker Electrocat, meant to entertain kitties and kids alike. The device features a 3D-printed…

-

GorillaBot, an eight-servo racing quadruped

Reading Time: < 1 minuteGorillaBot, an eight-servo racing quadruped Arduino Team — September 1st, 2020 La Toulouse Robot Race is an annual racing event held in Toulouse, France, which includes a 10-meter autonomous sprint for multi-legged robots. The current record for quadrupeds is 42 seconds, so Sebastian Coddington decided to construct a robot in hopes of…

-

This air hockey robot never loses

Reading Time: < 1 minuteThis air hockey robot never loses Arduino Team — August 18th, 2020 Air hockey is normally a two-player affair, but not for this student-built robot. The table features a designated human goal with a touchscreen GUI for settings and control. The second goal is guarded by an autonomous striker, attached to…

-

Build a Raspberry Pi robot buggy with your kids

Reading Time: < 1 minute[youtube https://www.youtube.com/watch?v=ZrxqaF1ZHOA?feature=oembed&w=500&h=281] Join us for Digital Making at Home: this week, young people can build a Raspberry Pi robot buggy with us! Through Digital Making at Home, we invite kids all over the world to code and make along with us and our new videos every week. So get your Raspberry…

-

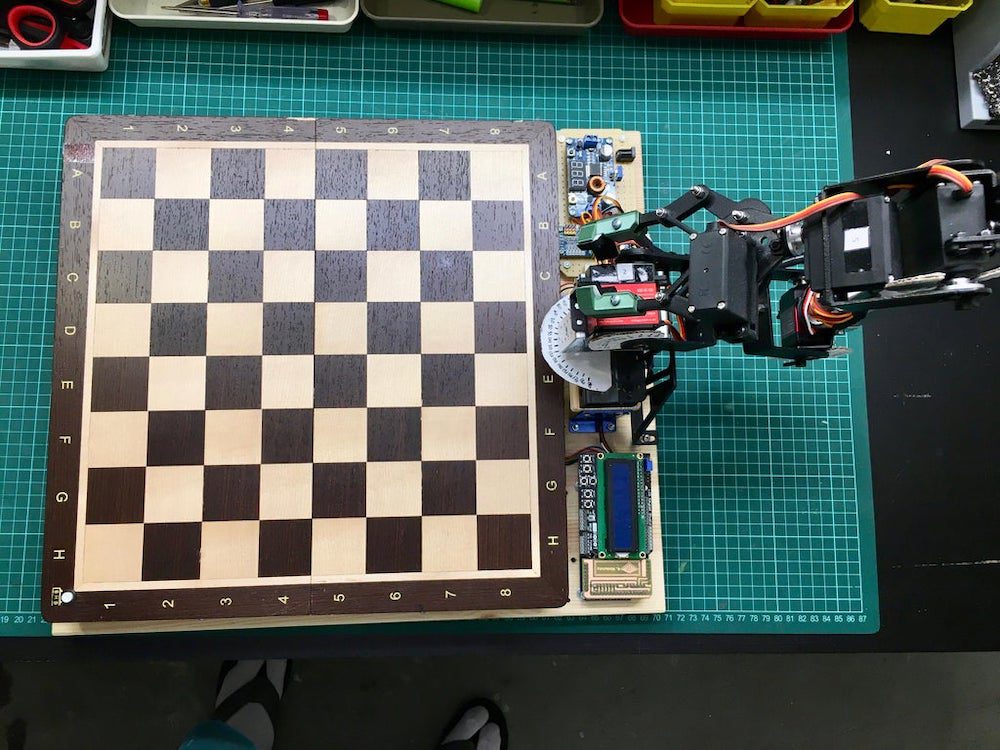

Arduino-controlled robot arm is ready to play you in a game of chess

Reading Time: < 1 minuteArduino-controlled robot arm is ready to play you in a game of chess Arduino Team — August 15th, 2020 If you’re tired of playing chess on a screen, then perhaps you could create a robotic opponent like Instructables user Michalsky. The augmented board runs micro-Max source code, enabling chess logic to be executed…

-

mOLOID is a pet like no other

Reading Time: 2 minutesmOLOID is a pet like no other Arduino Team — August 4th, 2020 As a part of their masters program at the University of Stuttgart, Jan Ingo Haller and Lorin Samija created a robotic pet that moves in a manner that may not be immediately evident. With the internals obscured by a…