Schlagwort: robotics

-

An Arduino Leonardo-powered, 3D-printed robotic arm designed from scratch

Reading Time: 2 minutesGetting started in the world of robotics can be a very challenging task, even for more experienced hobbyists, due to how difficult it can be to achieve smooth and precise motion through programming. Frustrated by the lack of accessible options, the YouTuber known as “Build Some Stuff” decided to not only design his own, but…

-

Bendy robotic tank steers by flexing

Reading Time: 2 minutesJames Bruton has become something of a YouTube sensation by experimenting with unusual drive mechanisms for his robots. While he does do other things, most of his projects seem to focus on designing, building, and evaluating drive types that are far outside of the norm. His newest project is no different. It…

-

Mini WALL-E robot delivers gifts

Reading Time: 2 minutesWhile brainstorming gift ideas, Professor Boots settled upon creating a tiny present-delivering robot that could move around on its own power. Because WALL-E’s design already has a built-in compartment and is quite memorable, it became the jumping off point for the project. The entire robot is 3D-printed from a combination of rigid PLA for the…

-

A very nimble DIY hexapod robot

Reading Time: 2 minutesWhile robots can get around on two legs (or even none), it is difficult to get a smooth and efficient gait. Moving up to four legs improves the situation a bit, but each of those legs will still need multiple joints and careful balance for the robot to move in a stable…

-

The weird and wonderful history of chess-playing robots

Reading Time: 4 minutesWho said robots had to be all work and no play? For many years, people have been designing and building robots not just to help with chores, but to help us win games. Possibly the most famous examples of this are the robots that play chess. In this article, we’ll take a…

-

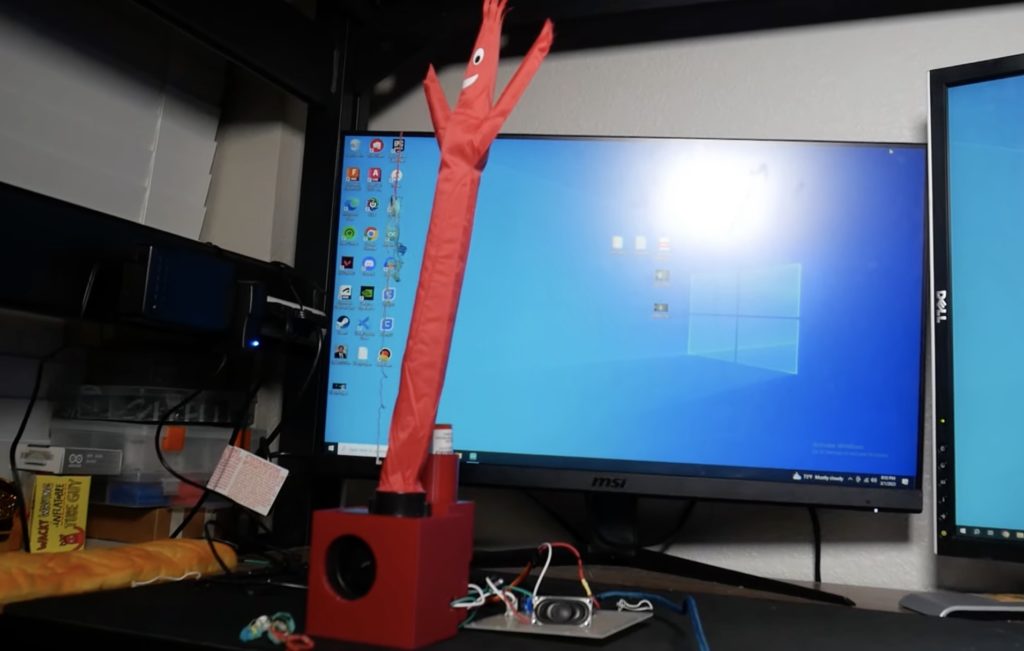

Celebrate good grades with this Arduino-powered robot

Reading Time: 2 minutesFor some students, getting decent grades or even finding the motivation to attempt to do schoolwork is a challenge, and this is often met with incentives such as money, praise, or simply avoiding embarrassment. Adam Soileau of element14 Presents had the idea to build a robot, which is an incentive unto itself by…

-

James Bruton’s robot centipede of many legs

Reading Time: 2 minutesStrangely, no centipede has exactly 100 legs. They can have either more or fewer than 100 legs, but not exactly 100 because they always have an odd number of pairs. Sadly, that means that James Bruton’s centipede robot is anatomically incorrect — though cool nonetheless. Bruton built this centipede robot as a scaled-down prototype,…

-

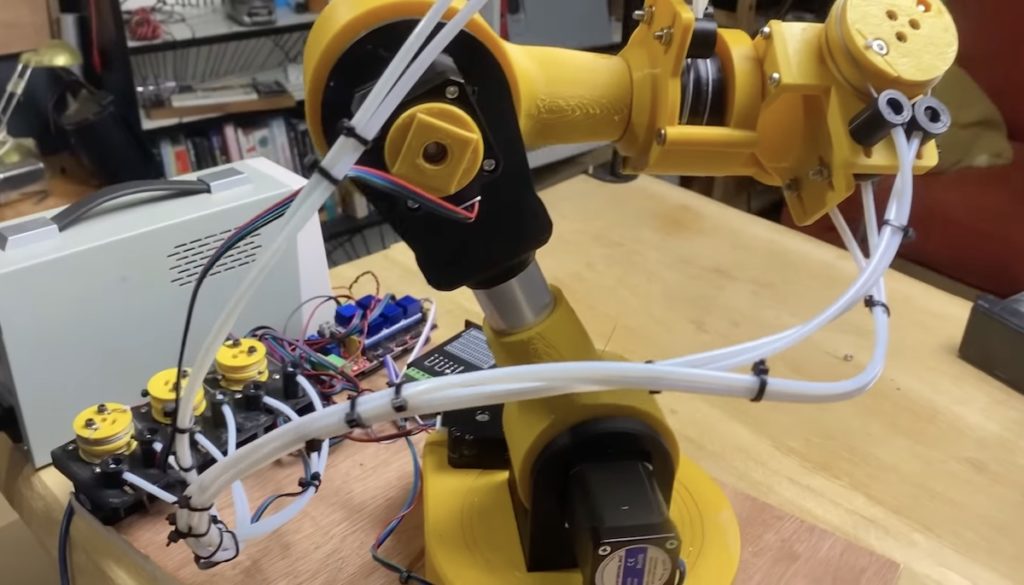

Controlling a robot arm over the internet

Reading Time: 2 minutesFor those with an interest in robotics, there is little in this world more enticing than a robot arm. A rover may be able to drive around, but so can a cheap RC car. A robot arm, on the other hand, can do real work, like stacking blocks or moving colored balls…

-

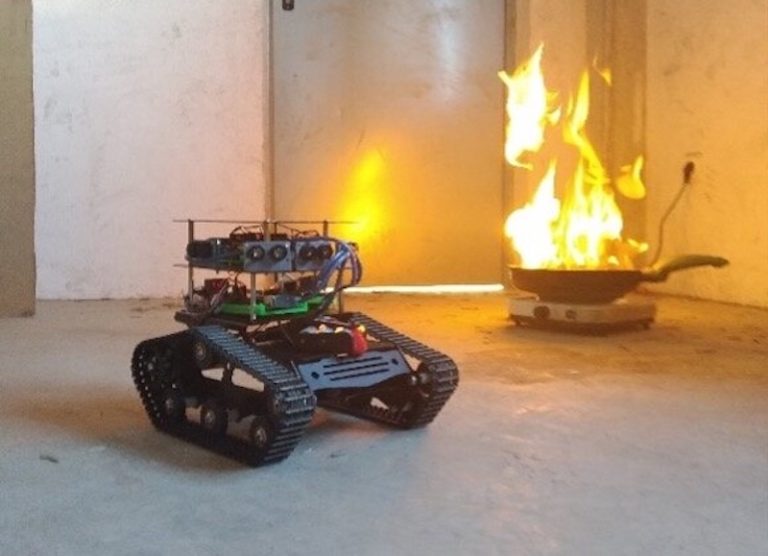

This little robot helps fight fires

Reading Time: 2 minutesFirefighting is a dangerous profession, but it is possible to mitigate some of that danger with good data. When firefighters entered a burning building, their biggest fear is the unknown. They don’t know if they can trust the structural integrity of the building, if there is a pocket of toxic or explosive…

-

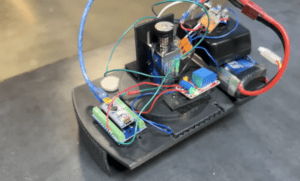

This 3D-printed robot is made for sumo battle tournaments

Reading Time: 2 minutesWhile the majority of makers are unable to afford the fancy equipment and components that go into modern state-of-the-art battle robots, there do exist lesser-known tournaments for more DIY designs, including sumo robot battles. Instructables user noclaf8810373’s design incorporates all of the high-powered components one would expect to find, along with an innovative defense mechanism. Construction…

-

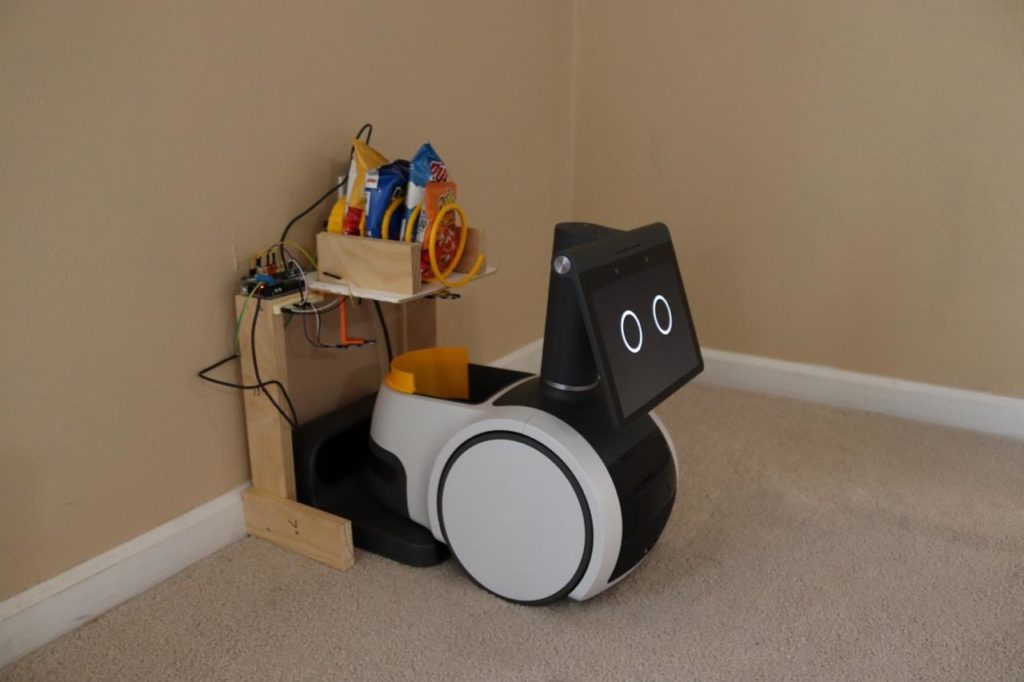

Snacky, the snack dispenser, enables snack delivery

Reading Time: 2 minutesSometimes you get a hankering for a snack, but there is no snack within arm’s reach. Such a situation is a tragedy and exactly what we built society and technology to avoid. To prevent this frankly appalling possibility, Michael Rigsby made Snacky, which is a snack-dispensing system that lets Amazon Astro robots…

-

Robot collects ping pong balls after matches

Reading Time: 2 minutesIf you frequent driving ranges, you’ve probably seen a machine (often attached to the front of an armored golf cart) designed to pick up golf balls. Because a driving range can easily fill up with thousands of golf balls an hour, such machines are necessary. After noticing that nobody wanted to pick…

-

This search and rescue robot creates 3D maps of disaster areas

Reading Time: 2 minutesIf you look at footage from the search and rescue efforts following any disaster, you’ll see that first responders have a very difficult time navigating through rubble to find people in need of emergency care. They also have to take extra precautions, as gas line ruptures and other hazards present dangers they…

-

The Infineon team’s XXL Chatbot offers you yuletide greetings

Reading Time: 2 minutesInfineon is one of the world’s largest semiconductor manufacturers, but the company is made up of regular people like any other. Many of those people just happen to be engineers and they like to build gadgets and gizmos like the rest of us. Following a water cooler discussion about who had the…

-

Celebrating the community: Selin

Reading Time: 4 minutesWe are so excited to share another story from the community! Our series of community stories takes you across the world to hear from young people and educators who are engaging with creating digital technologies in their own personal ways. Selin and her robot guide dog IC4U. In this story we introduce…

-

Increase a robot arm’s payload capacity by relocating its wrist motors

Reading Time: 2 minutesTo give an electric car more range, you need a bigger battery pack. But that adds weight, so you need bigger motors and more battery capacity to compensate. This creates a vicious cycle and robot arms are susceptible to a similar problem. A robot arm needs to lift its own weight in…

-

Mole crab robot burrows into sand using flexible legs

Reading Time: 2 minutesRevolutionary new technologies tend to require small, incremental developments. For example, physicist Julius Edgar Lilienfeld filed a patent for a transistor way back in 1925. But it wasn’t possible to actually build transistors until semiconductor production caught up in 1947 — something that took decades of “boring” materials research. Such research may…

-

This Andor-inspired droid moves like the real B2EMO

Reading Time: 2 minutesThe new Andor TV show, set in the Star Wars universe prior to the events of Rogue One, is already a hit and a big part of that is thanks to the B2EMO droid. Like many of the other droids in the Star Wars franchise, B2EMO manages to be very expressive despite being cold, hard steel. It conveys emotions…

-

This Valorant fan made his own functional Boom Bot replica

Reading Time: 2 minutesValorant is a free-to-play 5v5 first-person shooter game. As in most shooters, players want to avoid getting shot. One way they can prevent incoming fire is to use Boom Bot, which is a little robot that will drive forward and chase enemies before exploding — while the player stays safely hidden out of…

-

James Burton is giving legs their snakes back

Reading Time: 2 minutesJames Bruton gave that title to his most recent video as a good-natured jab at Allen Pan’s project about “giving snakes there legs back.” In Pan’s video, he built a robotic exoskeleton to let snakes walk around on motorized legs. But as Bruton noted in his video intro, those legs didn’t look…

-

Crack combination locks with this nifty robot

Reading Time: 2 minutesBig names on YouTube like LockPickingLawyer show us that a skilled individual can pick just about any lock that accepts a key. As it turns out, combination padlocks are also very easy to decode and it is even possible to automate that process so that a robot can do the job. Doing…

-

Beating unscrupulous arcade owners at their own games

Reading Time: 2 minutesMark Rober isn’t just a talented mechanical engineer and entertaining personality, he is also something of a champion of justice for the common man. He’s already proved that several times with his famous yearly porch pirate-targeted pranks, but now he’s taking on the corrupt fat cats running arcades for children. Those arcades…