Schlagwort: Prusa Research

-

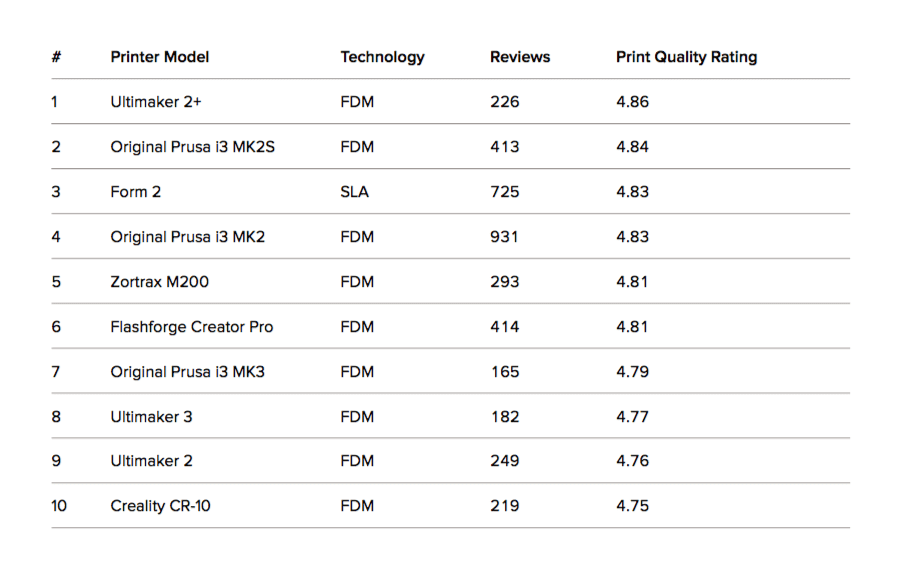

Ultimaker and Prusa Vie for Dominance in 3D Hubs Trend Report

Reading Time: 5 minutesUltimaker! HP! Prusa Research! New York City! Some fascinating insights into the 3D printing industry, courtesy of the latest 3D Hubs Trend Report. It’s the beginning of a new business quarter, and for 3D printing fanatics that means only one thing. It’s time for another 3D Hubs Trend Report. The 3D Hubs…

-

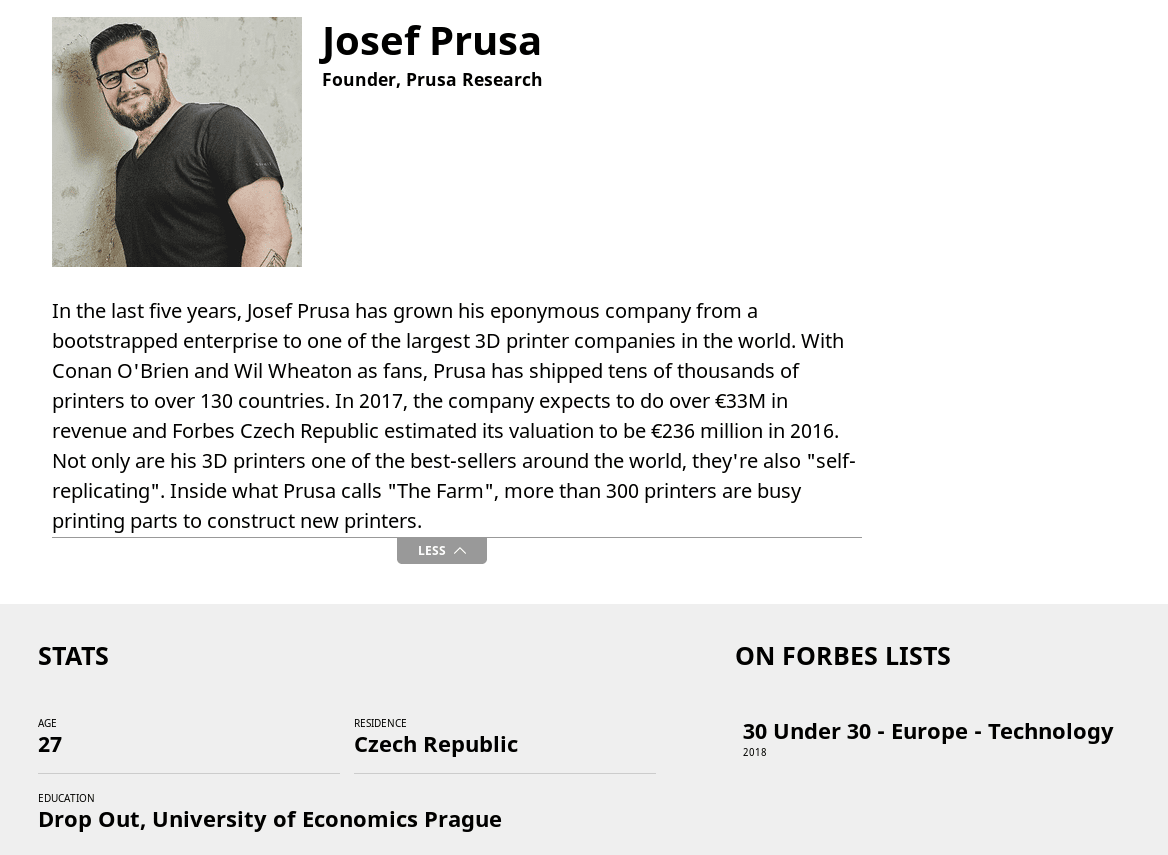

Spot for Josef Prusa on Forbes 30 Under 30 in European Technology List

Reading Time: 3 minutesJosef Prusa nabs himself a coveted spot on the Forbes 30 Under 30 list for Technology in Europe, and shares a status update on the Original Prusa i3 MK3 3D printer two months after shipping began. Don’t Miss: All3DP Visits Josef Prusa at the New Prusa Research Facility It’s been officially two…

-

Building the Original Prusa i3 MK3: Review the Facts Here!

Reading Time: 2 minutesSo what’s the big deal about the Original Prusa i3 MK3? It’s pitched as a refinement of everything Prusa Research have achieved to date; more than a reliability upgrade, but a new and improved desktop 3D printer with some awesome new features. Where the previous model offered astonishing print quality for the…