Schlagwort: prosthetics

-

Designing a 3D-printed EMG bionic hand as a low-cost alternative to prosthetic limbs

Reading Time: 2 minutesThe cost of a new prosthetic arm can range from several thousand dollars to tens of thousands, putting them out of reach for many people. Ahmad Ikram recognized this need and decided to design and build a far cheaper, open source version that has myoelectric capabilities. To begin this project, Ikram decided upon using…

-

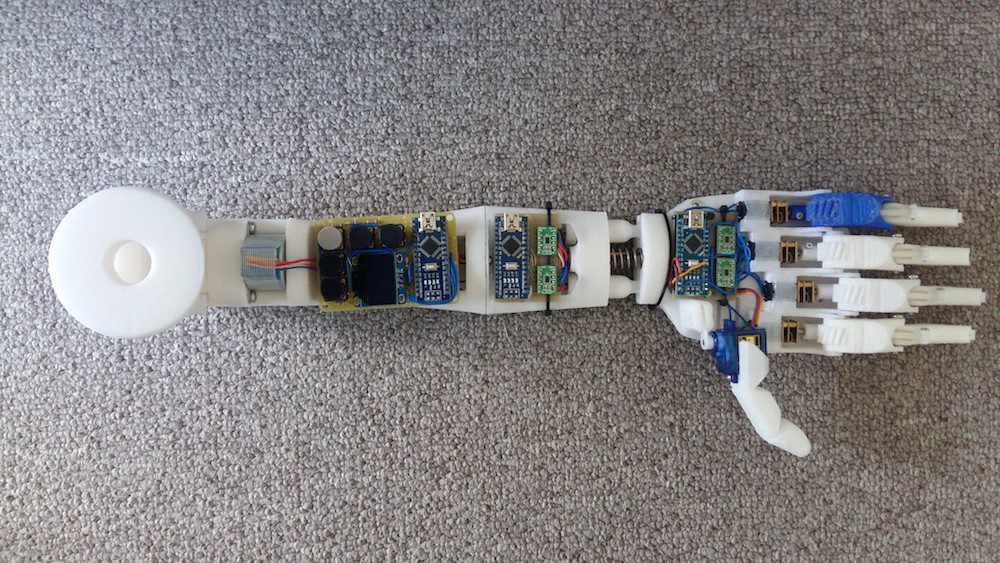

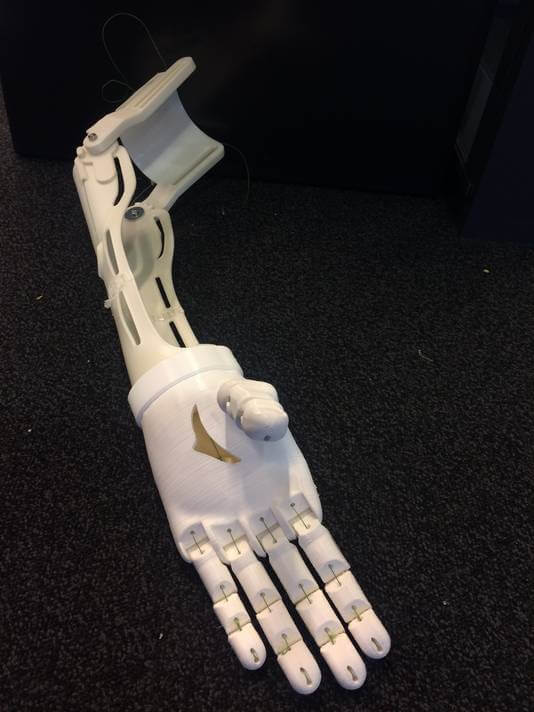

A low-cost, 3D-printed transhumeral prosthesis

Reading Time: 2 minutesA low-cost, 3D-printed transhumeral prosthesis Arduino Team — September 13th, 2019 To help a patient in his country with a congenital limb deficiency, Buzi Nguyen has designed a 3D-printed transhumeral—above the elbow—prosthesis prototype. The device features 10 degrees of freedom, including independent control of four fingers and a thumb, along with movement…

-

A low-cost, 3D-printed transhumeral prosthesis

Reading Time: 2 minutesA low-cost, 3D-printed transhumeral prosthesis Arduino Team — September 13th, 2019 To help a patient in his country with a congenital limb deficiency, Buzi Nguyen has designed a 3D-printed transhumeral—above the elbow—prosthesis prototype. The device features 10 degrees of freedom, including independent control of four fingers and a thumb, along with movement…

-

Doctor Drives to Sierra Leone with Ultimaker 3D Printer to Make Prosthetics for Children

Reading Time: 3 minutesDoctor Lars Brouwers is driving from the Netherlands to Sierra Leone with an Ultimaker 3D printer to teach locals how to print limb prosthetics for children. With a friend by his side, Brouwers set off on the ultimate road trip. The Dutch doctor is currently en route to the Innovate Salone program in…

-

5-Year-Old Star Wars Fan Receives 3D Printed Stormtrooper Prosthetic

Reading Time: 3 minutesFive-year-old Jacob Taggart is a huge Star Wars fan with a physical disability. For Christmas, the MORE Foundation gifted him with a 3D printed prosthetic arm inspired by the Stormtrooper outfit. Over the last couple of weeks, millions and millions of people have poured into their local theatre to see Star Wars: The…