Schlagwort: Opta

-

This machine lets you practice baseball solo, similar to Topgolf

Reading Time: 2 minutesTopgolf has a pretty brilliant business model: let golfers do the fun stuff (driving balls at max power), without any of the complications, time commitments, or logistics of running through a full 18-hole course. Batting cages exist to do something similar for baseball, but Pete LeMaster didn’t want to practice batting —…

-

This robotic tongue drummer bangs out all the ambient hits

Reading Time: 2 minutesIf you like to listen to those “deep focus” soundtracks that are all ambient and relaxing, then you’ve heard a tongue drum in action. A tongue drum, or tank drum, is a unique percussion instrument traditionally made from an empty propane cylinder — though purpose-built models are now common. Several tongues are…

-

Tecnoseta revives the silk industry with open-source innovation

Reading Time: 3 minutesThe silk industry has a rich history in Italy, but modern challenges have brought this centuries-old tradition to the brink of decline. Once a cornerstone of the rural economy in Italy, with a strong presence in Zagarolo, Rome, silk production has dwindled in the country due to industrial developments, synthetic fibers’ growing…

-

This belt grinder uses an Arduino Opta micro PLC

Reading Time: 2 minutesA mainstay in most machine shops, the belt grinder assists in greatly increasing the speed at which parts can be ground down in a safer, more controlled manner compared to an angle grinder. As an effort to build a tool like this one for the first time, Julien Alexandre chose to use…

-

Controlling a drum machine with the Arduino Opta

Reading Time: 2 minutesMakers have long asked the question “why bother with an expensive PLC when I can just use an Arduino?” The answer comes down to the priorities and needs of industrial clients. In a factory automation setting, the client will prioritize durability, reliability, and serviceability over the one-time purchase price of the device…

-

Expanding possibilities: Blues Wireless amplifies Opta’s connectivity

Reading Time: 2 minutesBlues Wireless and Arduino have joined forces to create the game-changing Blues Wireless for Arduino Opta, unveiled this week at the Automate Show in Chicago. The expansion module is an affordable solution to enhance connectivity options for Arduino Opta micro PLCs, and marks a significant milestone in PLC technology and in making…

-

Introducing Opta Expansions: scalable simplicity!

Reading Time: 2 minutesLast year, we launched the Arduino Pro Opta: it was an instant success with our community, and allowed us to reach PLC engineers with a new solution specifically designed for their needs. To further expand Opta’s capabilities, today the Arduino ecosystem welcomes various expansions that allow you to add new I/Os in…

-

Join us in Chicago at Automate Show 2024!

Reading Time: 2 minutesWe’re ready to bring our unconventional take on automation to one of North America’s leading industry events: come meet us at Automate Show in Chicago, taking place May 6th-9th, to find out more about open-source hardware and software solutions unlocking new opportunities to empower engineers and educators alike. Here are five great…

-

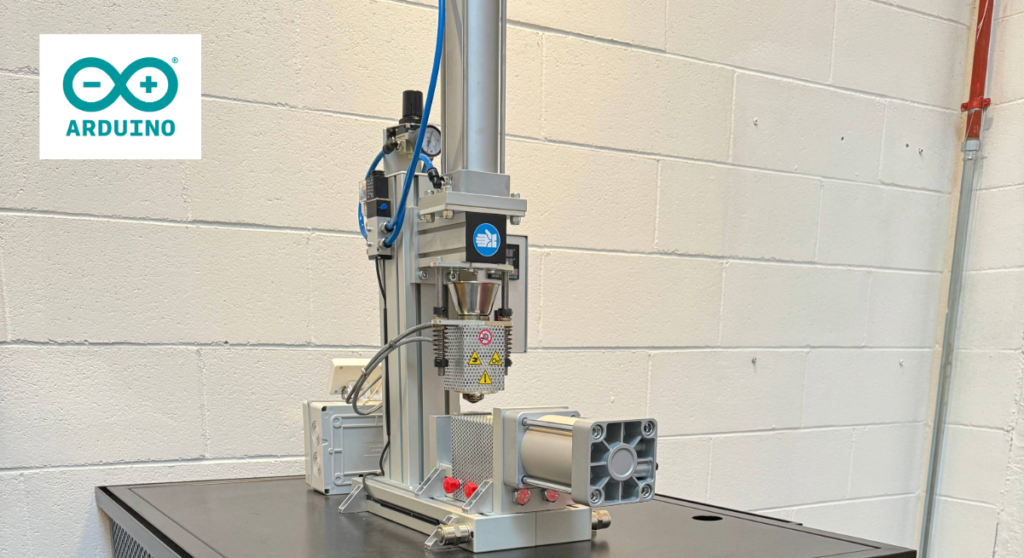

Arduino Cloud and Opta WiFi make an injection molding machine connected and smart

Reading Time: 3 minutesIn the rapidly evolving landscape of industrial technology, three interesting trends are intertwining to streamline processes, improve efficiency, and reduce downtime. They are retrofitting, remote control/monitoring, and power metering – and together, they make for a great strategy to upgrade and improve existing machinery, reaping all the benefits of connected things and…

-

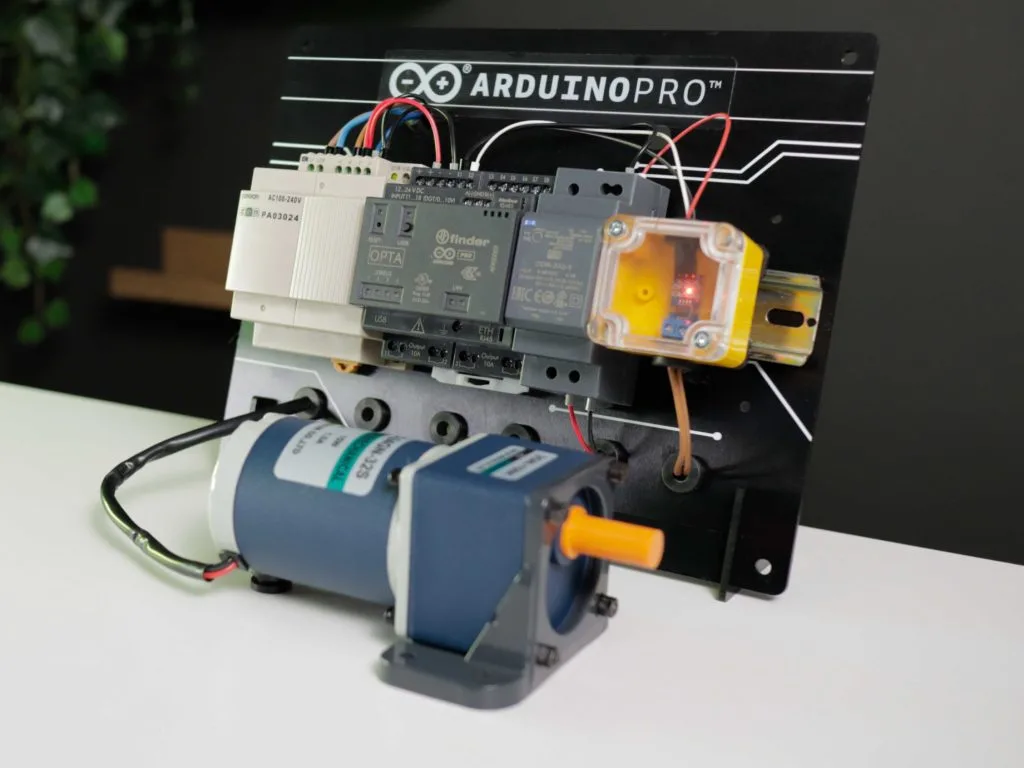

Introducing the new Arduino PLC Starter Kit: Plug into the future of industrial automation

Reading Time: 4 minutesIn a world where industrial automation is rapidly advancing, education often struggles to keep pace. This disconnect leaves a big gap in practical, industry-relevant skills among graduates. Addressing this critical need, we’re excited to introduce the Arduino PLC Starter Kit. Powered by the robust Arduino Opta mini PLC and backed by the…

-

Opta: Enhanced cybersecurity after HWG Sababa’s testing

Reading Time: 2 minutesConnecting machines and equipment to the internet became easier than ever when we launched the Arduino Opta micro PLC, enabling real-time control, monitoring, predictive maintenance and more – in industries ranging from smart agriculture to large-scale manufacturing to building automation. Supporting our well-known Arduino sketch programming experience and any of the five IEC…

-

Syncing tunes to Christmas tree lights with the Arduino Opta

Reading Time: 2 minutesWe all know that one neighbor who always goes the extra mile when decorating for the holidays, and after taking inspiration from these large displays of light and sound, Marcelo Arredondo, Andres Sabas, and Andrea ZGuz of the Electronic Cats crew decided to build a smaller version for their Christmas tree using the Arduino Opta micro PLC.…

-

Smart accommodation: Hotel room and rental property automation with Arduino Opta

Reading Time: 5 minutesHospitality professionals are constantly looking for ways to offer guests an enhanced experience while improving operational efficiency and optimizing energy management. To achieve this, they require cost-effective solutions that are easy to install and maintain while also providing the scalability of future-ready systems – such as automating hotel rooms or B&B rentals…

-

Meet Arduino Pro at tinyML EMEA Innovation Forum 2023

Reading Time: 3 minutesOn June 26th-28th, the Arduino Pro team will be in Amsterdam for the tinyML EMEA Innovation Forum – one of the year’s major events for the world where AI models meet agile, low-power devices. This is an exciting time for companies like Arduino and anyone interested in accelerating the adoption of tiny…

-

Ensure DC motor performance with anomaly detection based on energy monitoring

Reading Time: 5 minutes[youtube https://www.youtube.com/watch?v=jskIyHzcH7A?feature=oembed&w=500&h=281] The challenge Optimizing manufacturing processes is a requirement in any industry today, with electricity consumption in particular representing a major concern due to increased costs and instability. Analyzing energy use has therefore become a widespread need – and one that can also lead to early identification of anomalies and predictive…

-

Arduino Pro at SPS Italy 2023

Reading Time: 3 minutesMark your calendars: May 23rd-25th we’ll be at SPS Italia, one of the country’s leading fairs for smart, digital, sustainable industry and a great place to find out what’s new in automation worldwide. We expect a lot of buzz around AI for IoT applications – and, of course, we’ll come prepared to…

-

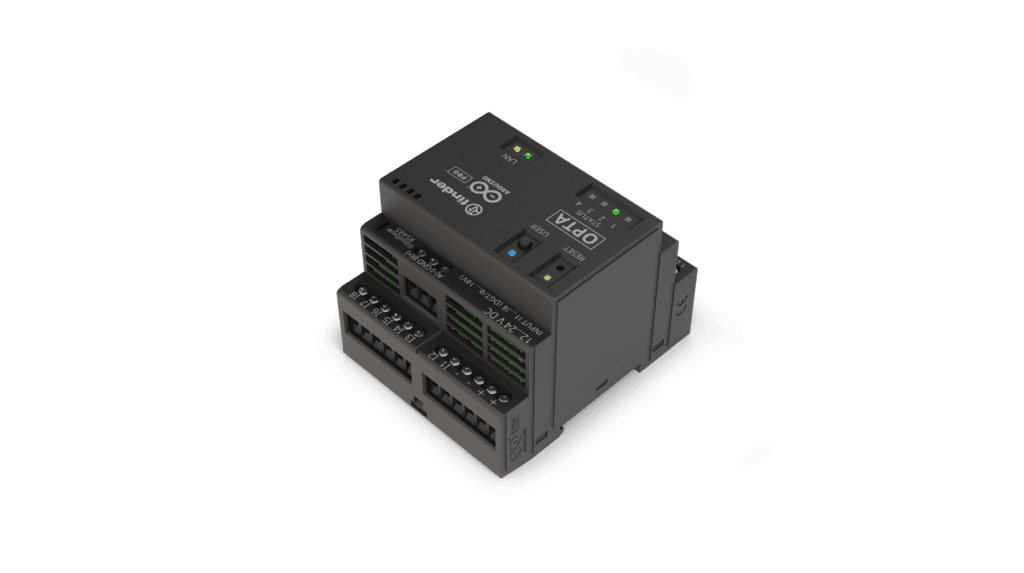

Welcome Opta, our first-ever micro PLC with Industrial IoT capabilities

Reading Time: 2 minutesWe can finally tell you all about the new product we had announced for SPS! Today, we are excited to expand the Arduino Pro range with Opta, our first micro PLC with Industrial IoT capabilities. We designed it specifically with PLC engineers in mind: supporting standard languages including LD (Ladder Logic Diagram)…