Schlagwort: Nano

-

These Shattered Space helmet replicas stay video game accurate using an Arduino Nano

Reading Time: 2 minutesStarfield, a game set in the vast expanse of our galaxy, is receiving a new expansion called “Shattered Space” in which players can don novel weapons and gear to take on the latest challenge. As part of its release, the expansion’s publisher Bethesda reached out to cosplayer Jonas Zibartas and tasked him with creating a…

-

This robotic kalimba plays melodies with an Arduino Nano

Reading Time: 2 minutesWith roots in Africa, the kalimba is a type of hand piano featuring an array of keys that are each tuned for a specific note, and upon plucking or striking one, a pleasant, xylophone-like sound can be heard. Taking inspiration from his mini kalimba, Axel from the YouTube channel AxelMadeIt sought to automate how…

-

Agitating homemade PCBs with ease

Reading Time: 2 minutesIf you want to make PCBs at home and you don’t happen to own a CNC mill, then you’ll probably need to turn to chemical etching. Use one of several different techniques to mask the blank PCB’s copper that you want to keep, then toss the whole thing into a bath to…

-

This Strandbeest-style coffee table can deliver drinks

Reading Time: 2 minutesMore than 30 years ago, Dutch artist Theo Jansen began astounding the world with his Strandbeesten walking sculptures. Even after decades, they have an almost mythical allure thanks to the incredibly fluid way in which they walk. They’re clearly constructs, but with gaits that are almost organic. Inspired by his fellow Dutchman,…

-

Giving a teenage pet turtle a synthetic pizza-ordering voice

Reading Time: 2 minutesIf B. F. Skinner’s famous research proved anything, it is that virtually all animals are capable of some degree of training. Training is really just taking advantage of an animal’s natural inclination to adapt for survival, which is something all living organisms do. With that in mind, YouTuber Bao’s Builds constructed a…

-

Exercise while you game with this interactive treadmill add-on

Reading Time: 2 minutesMotion-based controls for games have been around for decades, but even with the latest generation of virtual reality headsets, gaming is still done with relatively limited movement unless one has access to an expensive VR walking/running setup. As an effort to get more physical activity in, Iacopo Guarneri has developed a motion-capturing…

-

This miniature monorail stays upright with the help of gyro stabilization

Reading Time: 2 minutesMost monorail systems, like the kind at Disney and in Las Vegas, stay upright because the “rail” is actually a very wide beam. The car’s load tires (often literal truck or trailer tires) roll on top of that beam and guide tires clamp the sides of the beam, preventing the car from…

-

Adjusting office chair height with simple voice commands

Reading Time: 2 minutesA month ago, ElectronicLab modified his office chair with an electric car jack, giving it motorized height adjustment. That worked well, but required that he push buttons to raise or lower the seat. Pushing those buttons is a hassle when one’s hands are full, so ElectronicLab went back to the workbench to…

-

Patrol the pool with this Arduino Nano-powered DIY RC submarine

Reading Time: 2 minutesThere is something inherently intriguing about submarines that doesn’t seem to apply to other vehicles. Maybe that reflects our natural fears and phobias, or maybe it is a result of our curiosity about the mysterious depths. Maybe it is simply that most of us will never get the chance to ride in…

-

Ride safer with these DIY bicycle lights

Reading Time: 2 minutesMany people around the world live in cities designed for cars, with bicycle use being a distant afterthought. That makes cycling dangerous and lights can do a lot to make riding safer. That’s why Giovanni Aggiustatutto designed this DIY system that includes headlights, a taillight, turn signals, and even an integrated odometer/speedometer. …

-

What if robots could communicate with humans by emitting scents?

Reading Time: 2 minutesAlmost all human-robot interaction (HRI) approaches today rely on three senses: hearing, sight, and touch. Your robot vacuum might beep at you, or play recorded or synthesized speech. An LED on its enclosure might blink to red to signify a problem. And cutting-edge humanoid robots may even shake your hand. But what…

-

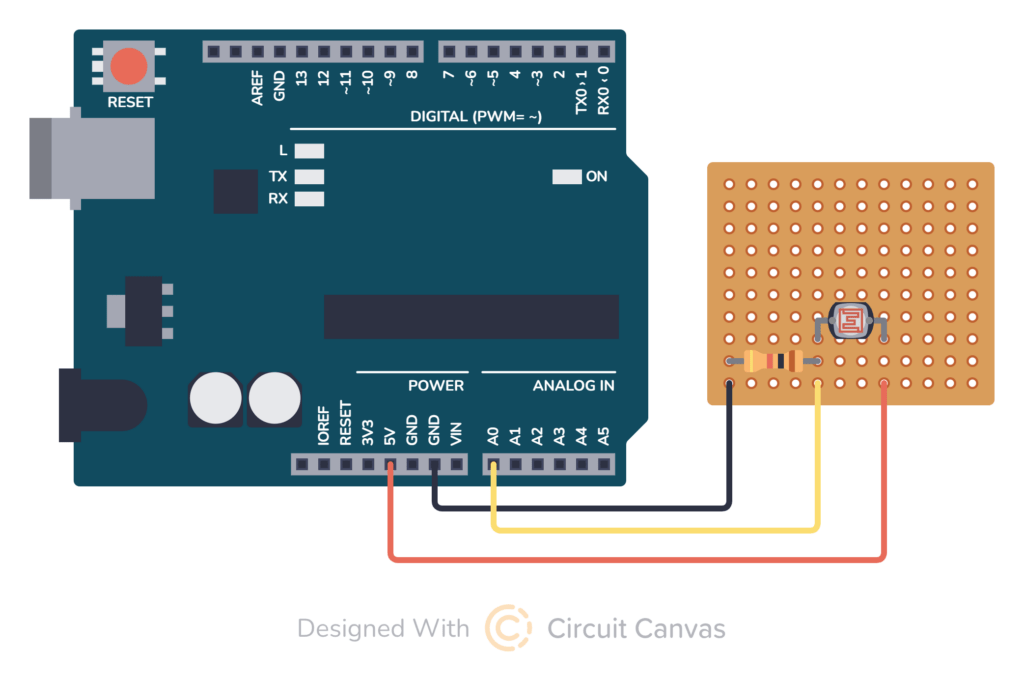

Circuit Canvas can help you quickly create illustrated wiring diagrams

Reading Time: 2 minutesGood documentation is extremely useful when conceiving, building, or sharing electronic circuit designs, but traditional schematics and technical drawings are difficult for non-professionals to interpret and create. Makers can benefit from intuitive illustrations that look good enough to share. Circuit Canvas, developed by Oyvind Nydal Dahl, makes it easy to quickly create…

-

Enjoy a perpetual solar eclipse with this machine

Reading Time: 2 minutesTotal solar eclipses are rare — at least from the perspective of any specific point on the planet. A total eclipse will occur somewhere on Earth once every 18 months or so, but that is more likely to track across the middle of the Pacific Ocean than wherever you happen to be. That made…

-

The Arduino-controlled Spin Meister helps spin up the perfect pizza

Reading Time: 2 minutesDedicated pizza ovens are all the rage right now, as they provide a better-distributed and higher heat that many find more preferable than a conventional kitchen oven. But even a nice gas-powered pizza oven like the Ooni Koda 12 will have some hot spots and cold spots. To get an even bake…

-

Self-leveling workbench can travel without trouble

Reading Time: 2 minutesAn actually level workbench is critical for many different jobs, such as pouring resin or calibrating sensors. But it is difficult enough to level a stationary workbench and that becomes a nightmare for a workbench that needs to roll around a shop on casters, as shop floors definitely aren’t level. That’s why Firth Fabrications…

-

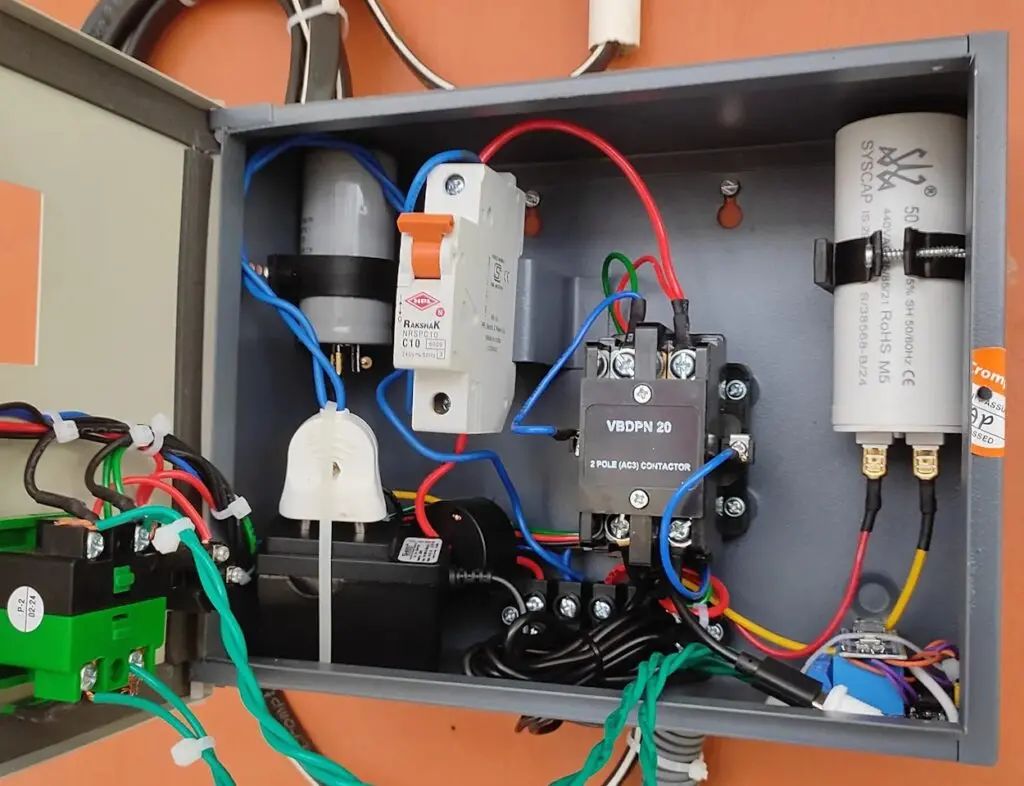

DIY submersible pump controller helps retrieve well water

Reading Time: 2 minutesIt might surprise our urban-dwelling readers, but wells are still very common in rural areas where it is difficult or prohibitively expensive to run utilities. The CDC reports that more than 15 million households rely on groundwater and wells — and that’s just in the United States. But few people haul up…

-

A beautiful custom calculator built with IV-12 VFD tubes

Reading Time: 2 minutesNixie tubes have been the go-to option for makers looking for retro display aesthetics for many years, because their distinct orange glow carries a lot of vintage appeal. But VFD (vacuum fluorescent display) tubes have been gaining in popularity recently and have different — though similar — appeal. Oskar took advantage of…

-

On-body LEDs help this guitar rock harder

Reading Time: 2 minutesYou don’t go to watch a band play live for the audio quality — most venues are atrocious in that regard. No, you go to enjoy the show as a whole and that includes the visuals. The more a band can do to make the performance look exciting, the more you’re going…

-

Check out these Arduino-powered research projects from CHI 2024

Reading Time: 4 minutesHeld in Hawaii this year, the Association of Computing Machinery (ACM) hosted its annual conference on Human Factors in Computing Systems (CHI) that focuses on the latest developments in human-computer interaction. Students from universities all across the world attended the event and showcased how their devices and control systems could revolutionize how…

-

Synjets provide non-contact haptic feedback

Reading Time: 2 minutesIf the COVID pandemic showed us anything, it is that our public spaces are overflowing with opportunity for germ transmission. In 2019, most people didn’t think twice about touching a gas pump handle or an ATM touchscreen, but it quickly became apparent that such contact presents a genuine risk. We have technology…

-

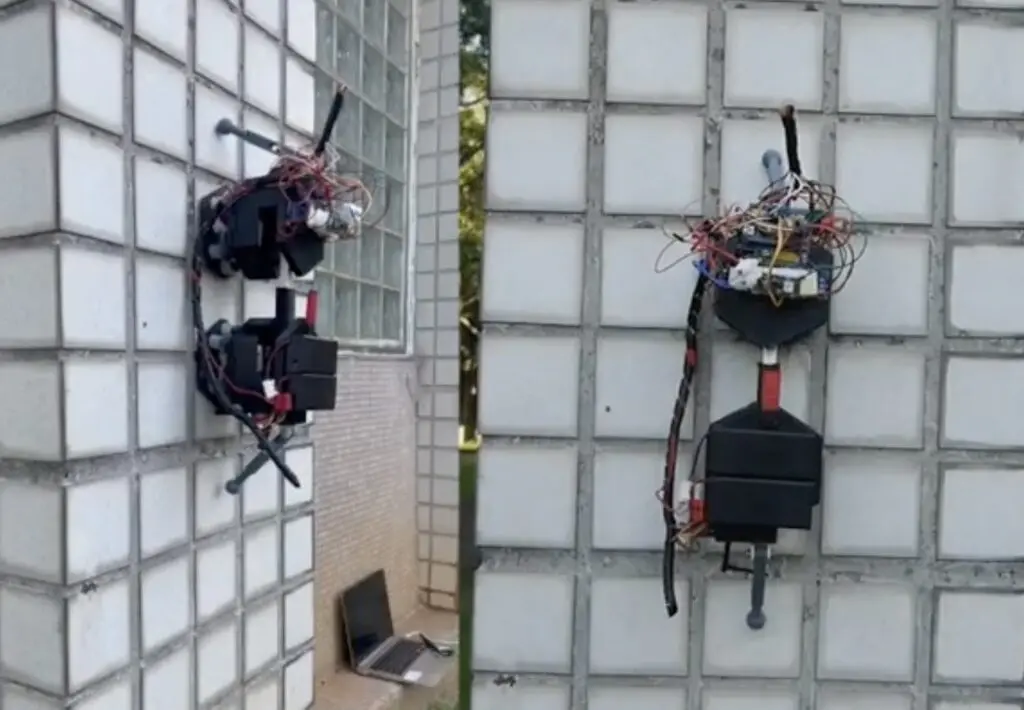

GLEWBOT scales buildings like a gecko to inspect wall tiles

Reading Time: 2 minutesA great deal of building maintenance expenses are the result of simple inaccessibility. Cleaning the windows are your house is a trivial chore, but cleaning the windows on a skyscraper is serious undertaking that needs specialized equipment and training. To make exterior wall tile inspection efficient and affordable, the GLEWBOT team turned…

-

Create your own affordable Arduino-powered smart glasses

Reading Time: 2 minutesWhen Google Glass launched in 2013, the public opinion seemed to be “interesting technology, but the world isn’t ready yet.” Now that more than a decade has passed, the world may finally be ready — especially with the omission of controversial features like video recording. If that appeals to you, then Akashv44…