Conventional hobby model rockets get their thrust from disposable motors containing an explosive propellant, like black powder. But unlike the gun powder in a firearm’s cartridge that uses a concussion-activated primer to ignite, model rocket enthusiasts ignite their motors using an electric arc. Simple launch controllers consist of little more than a battery, boost converter, and cables. But if you want something fancy, you should check out the Arduino Launch Control System.

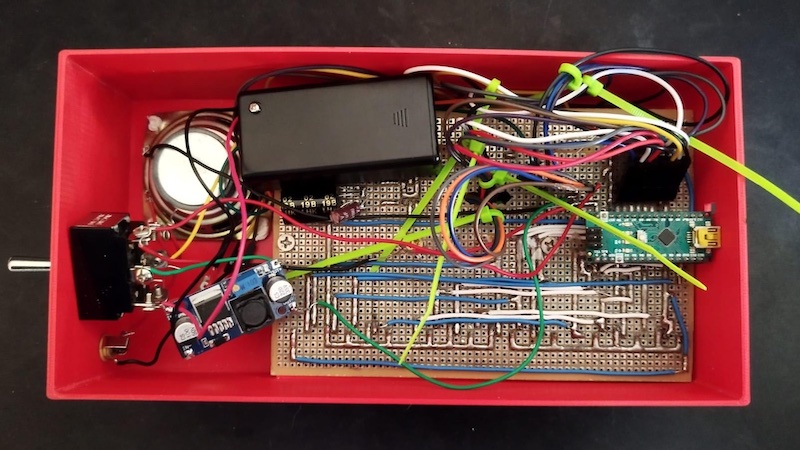

This robust launch controller provides environmental data and a great deal of safety. Its built-in sensors provides three key data points: temperature, humidity, and barometric pressure. That information can convey valuable insight when evaluating the performance of a rocket. On the safety side, this launch controller forces several layers of redundancy and checks. To launch a rocket, the user must connect two power supplies, insert and turn a key, push the safety and fire buttons at the same time, and hold those buttons for the entire countdown. That focus on safety makes this launch controller perfect for younger hobbyists.

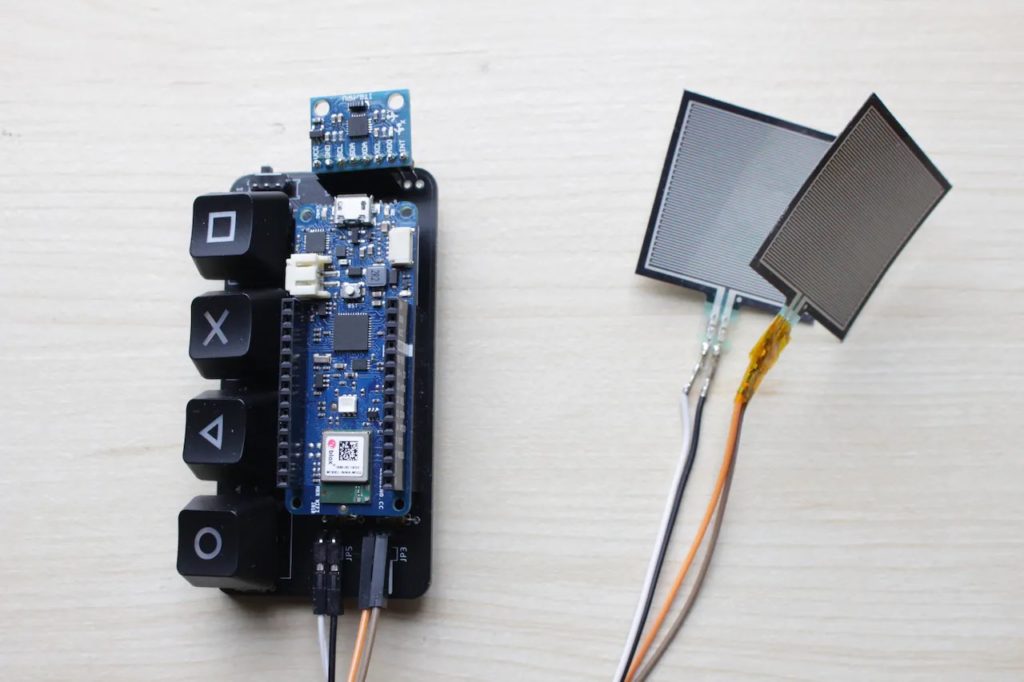

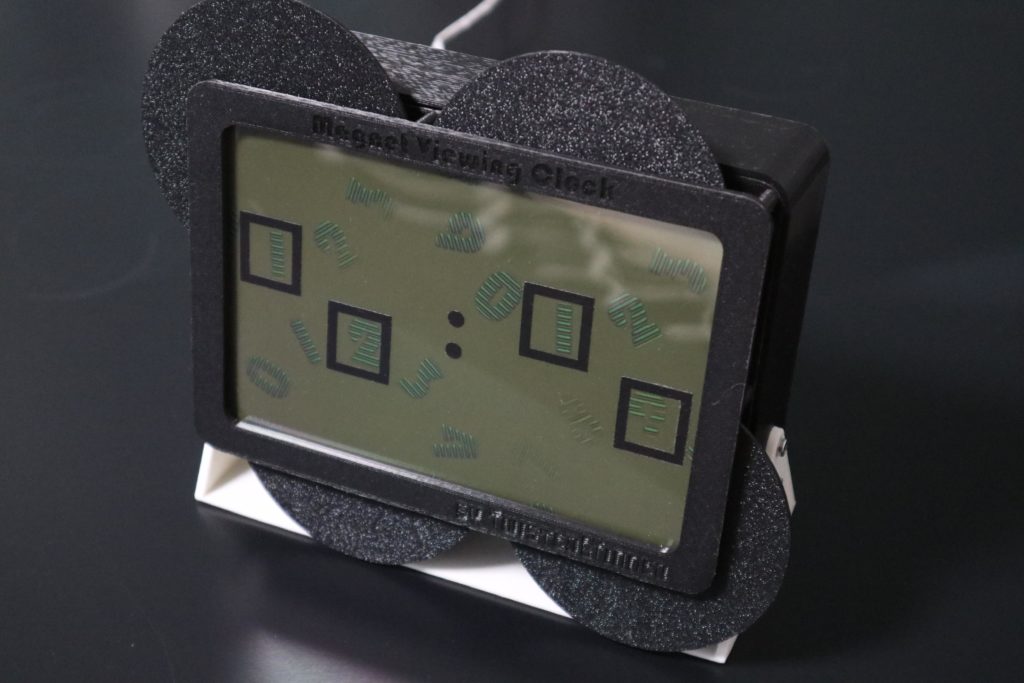

The full bill of materials is quite long, but the major components are an Arduino Nano board, a 16×2 character LCD, a BMP180 barometric pressure sensor, a DHT11 temperature/humidity sensor, and a DS1370 real-time clock. The enclosure is a small 13” toolbox with chipboard panel. Chipboard is very thick card stock that easy to cut, but strong enough for an application like this. The full build details are available on the Instructables tutorial page.

If you want all of the features of a high-end launch controller, but without the expense, then the Arduino Launch Control System makes for a great weekend project.

The post The Arduino Launch Control System is a model rocket enthusiast’s dream appeared first on Arduino Blog.

Website: LINK