— November 16th, 2021

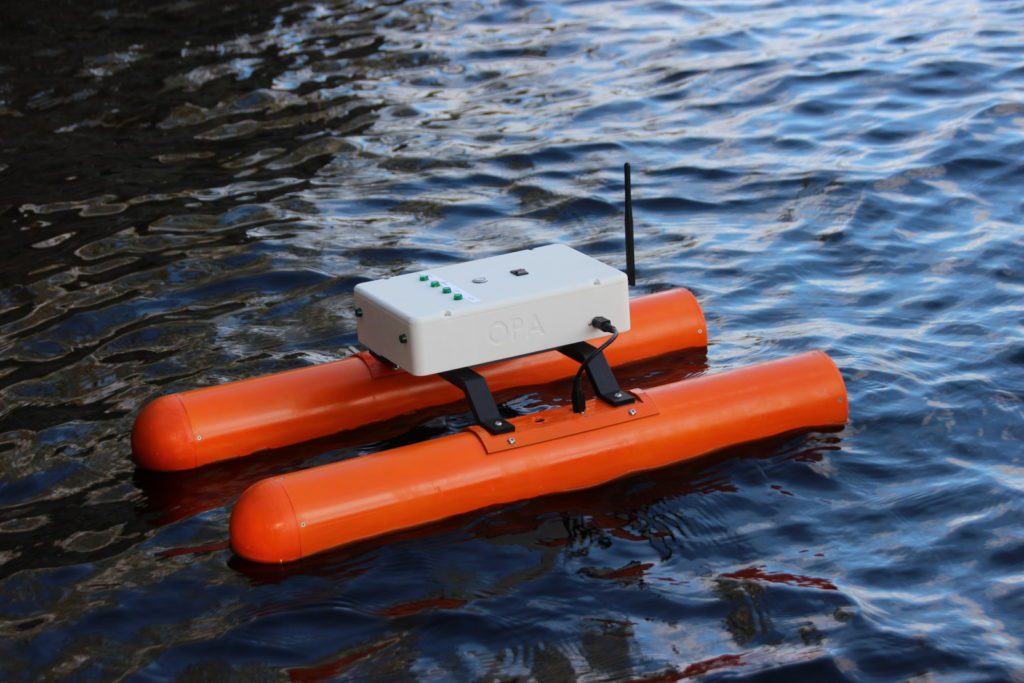

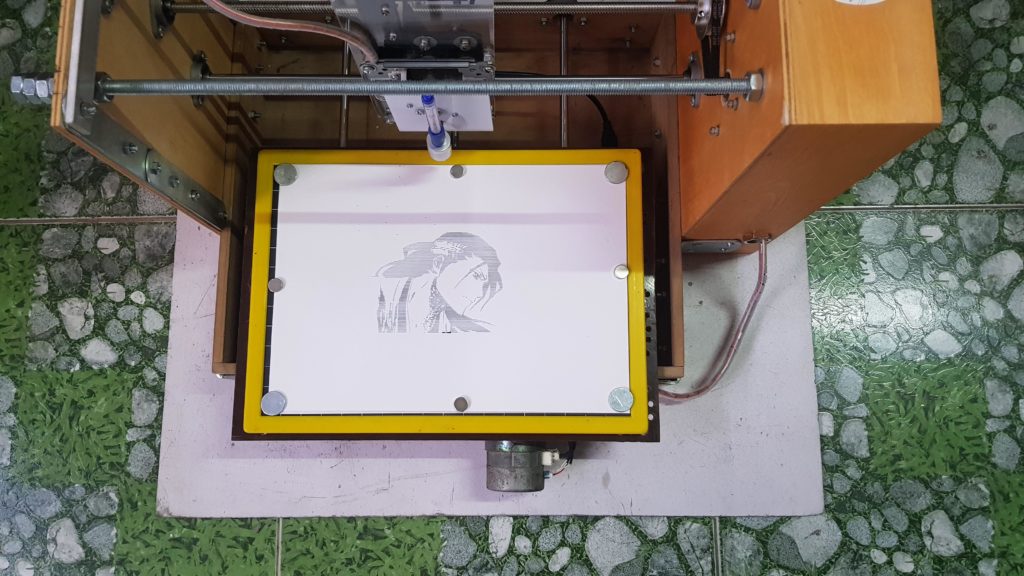

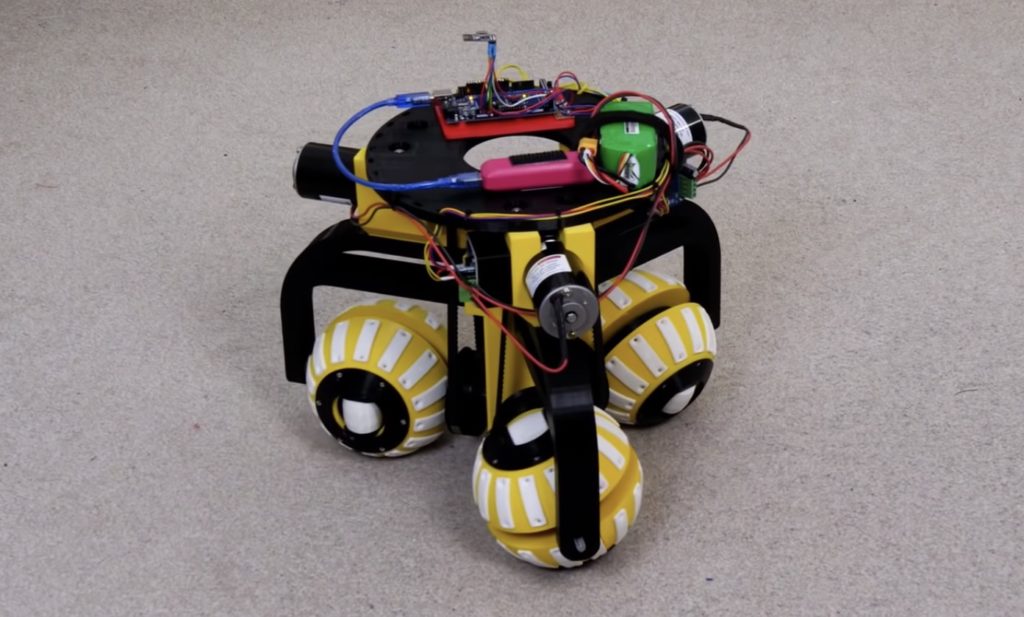

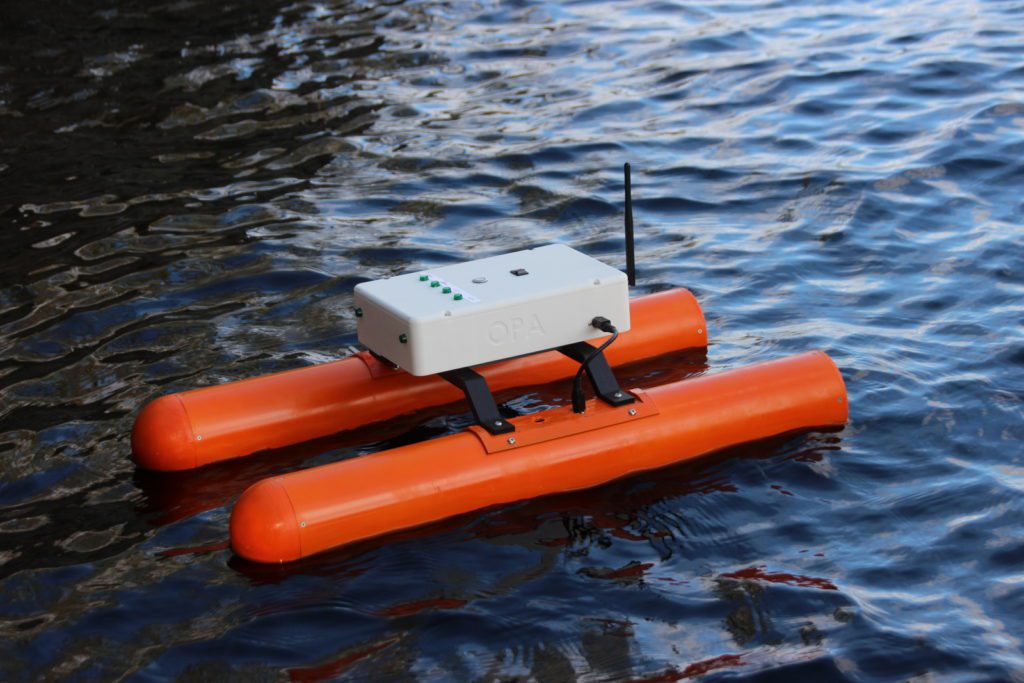

Starting with an idea in 2019, Redditor wesgood has been steadily working on the Opa — an autonomous 3D-printed boat that can navigate open water while relaying its telemetry back in real-time to a client device over WiFi. After creating a small prototype, Wes built a second one that featured a pair of pontoons held together with a couple of struts and a central platform. This design contains a single water jet that is situated in the back of each pontoon that takes in water and shoots it out at a high velocity, similar to a jet ski. Best of all, they can be independently throttled which eliminates the need for a rudder.

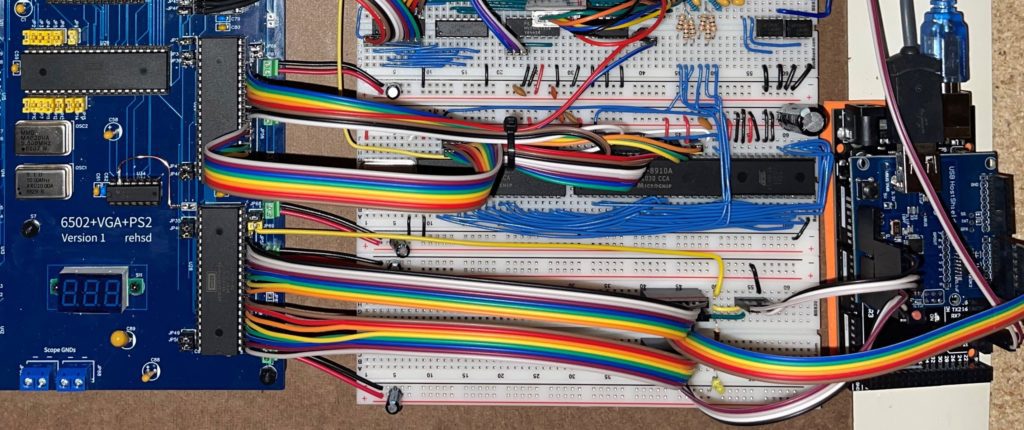

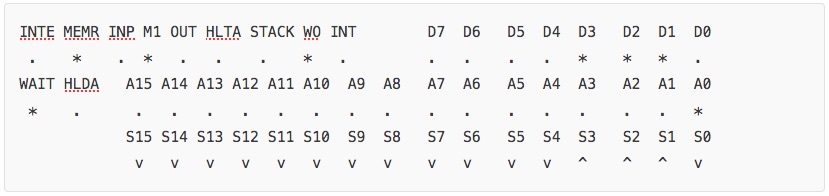

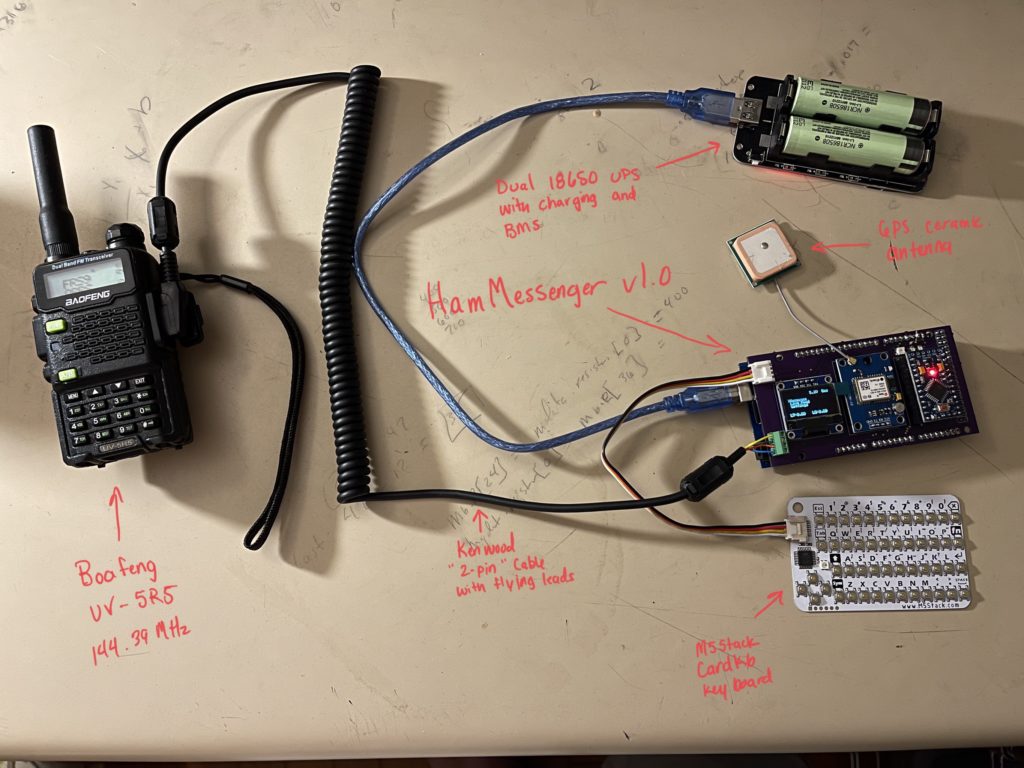

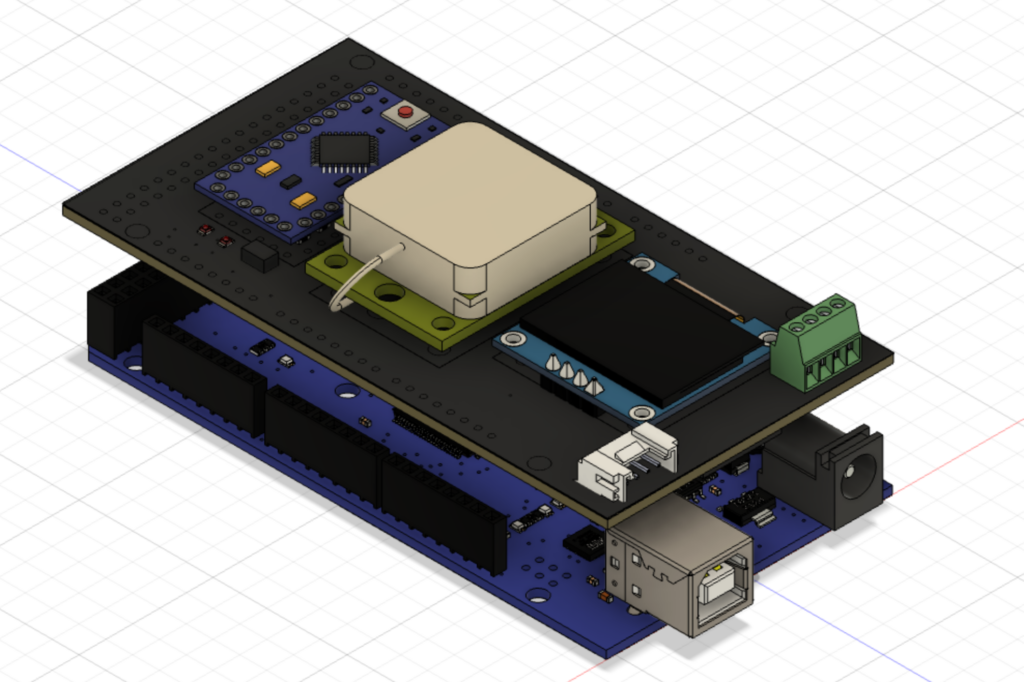

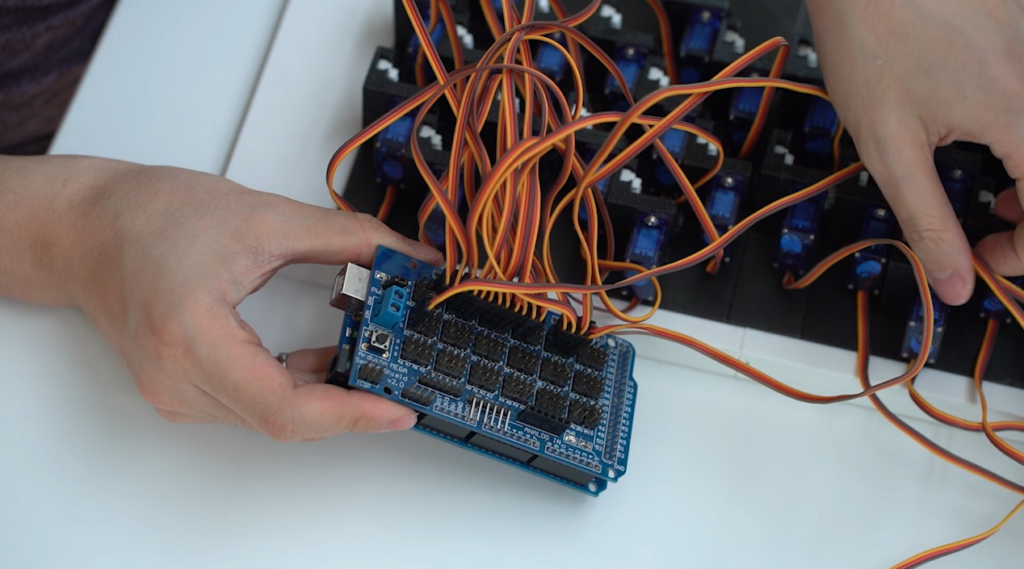

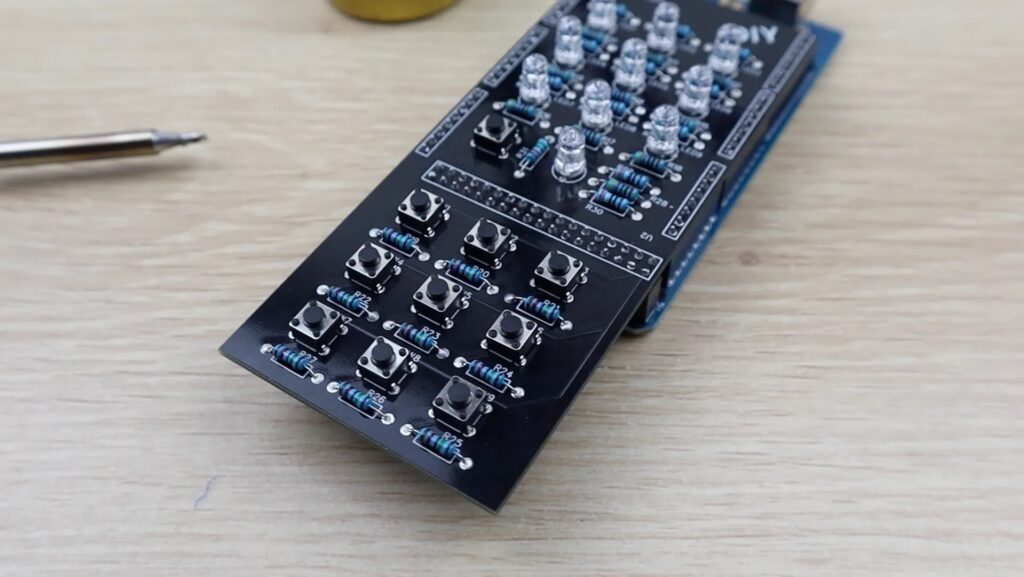

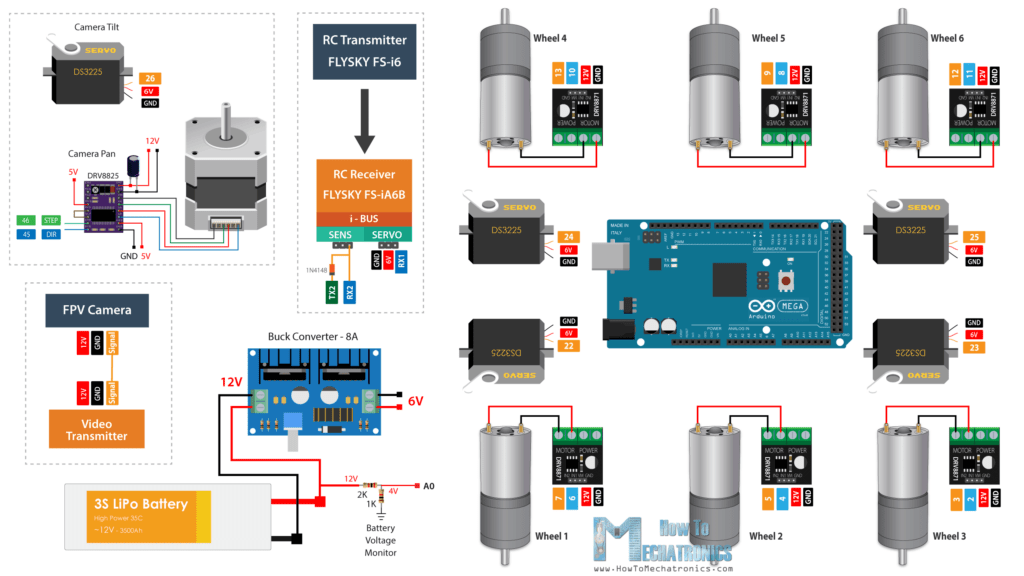

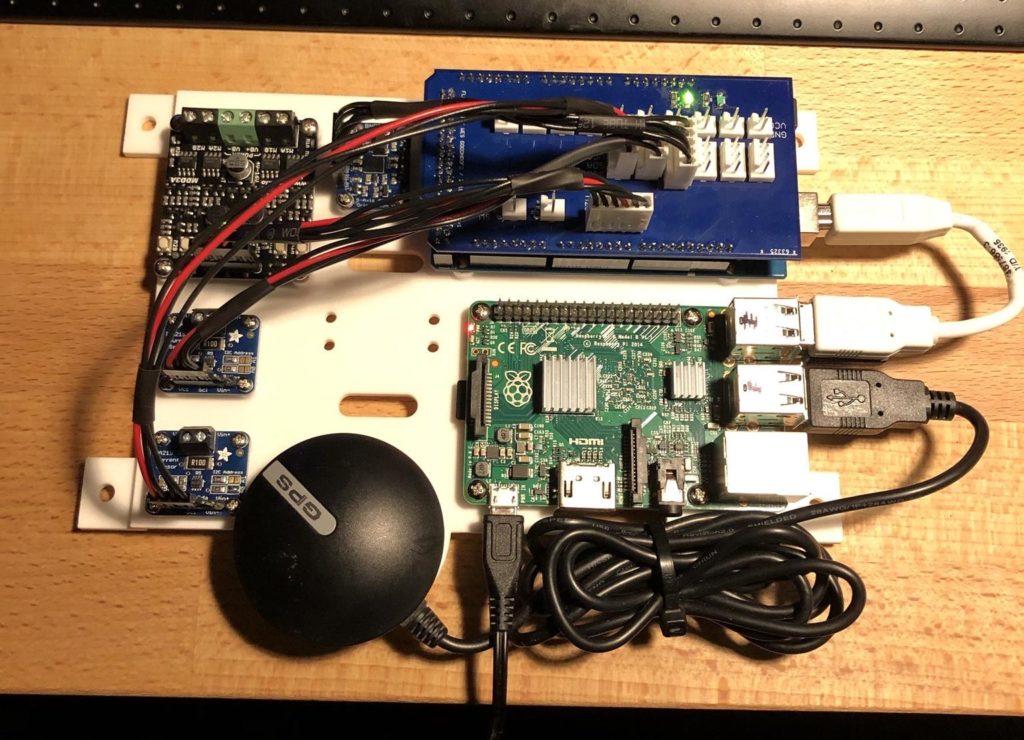

As far as circuitry goes, the Opa houses an Arduino Mega that has a custom shield on the top for controlling the pump motors and reading data from the onboard 9-DOF IMU and battery voltage/current sensors. An auxiliary Raspberry Pi runs Ubuntu Server, and its job is to coordinate data coming from a GPS receiver and information from the Arduino Mega with a wireless client device.

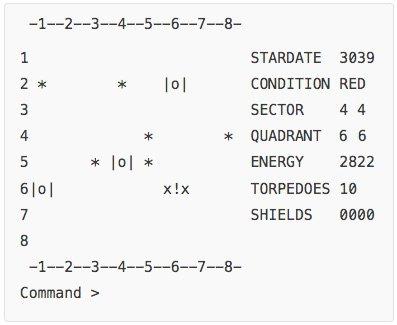

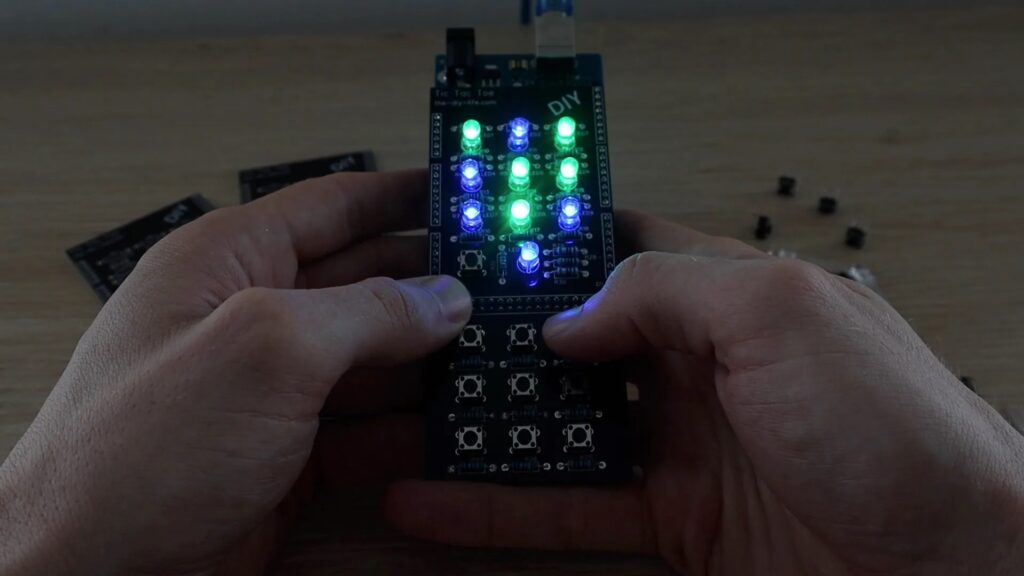

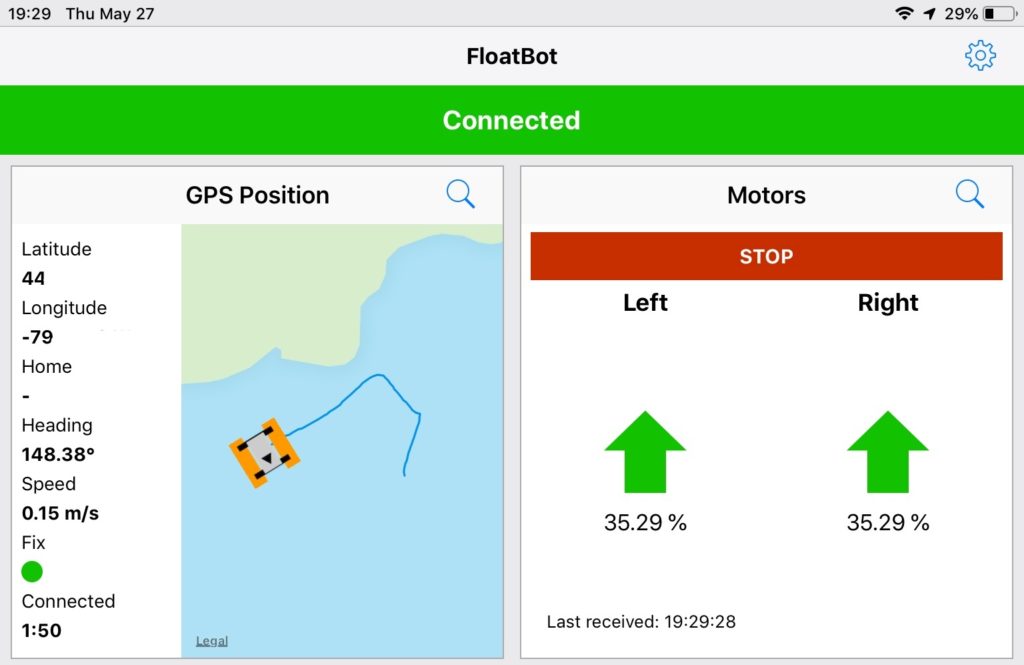

After getting the necessary software loaded onto the Arduino and Raspberry Pi, Wes placed them inside of a watertight enclosure on the top of the boat. His mobile app could then be used to see relevant telemetry, power consumption, and the current location of the raft overlaid on a map. Additionally, the user has the option to manually pilot the boat if they so desire as well.

To see more information about how the Opa was developed, visit Wes’ Imgur gallery here.

Website: LINK