Schlagwort: maritime

-

3D Printed Autonomous RoBoats Aim to Reduce Road Traffic in Amsterdam

Reading Time: 3 minutesResearchers from MIT CSAIL and the Amsterdam Institute for Advanced Metropolitan Solutions are working on a project called the RoBoat, an autonomous boat system that can be used as water taxis, or even be joined together to create floating structures and bridges. Imagine being able to start your morning off by hopping on…

-

3D Printable Syntactic Foams Could Help Submarines Reach Deeper Depths

Reading Time: 4 minutesA team of researchers from New York University School of Engineering have developed 3D printable syntactic foam materials. These foams are lightweight composites that offer exceptional buoyancy and strength, and are commonly used for submarine components. Scientists at the New York University Tandon School of Engineering have developed the first process to…

-

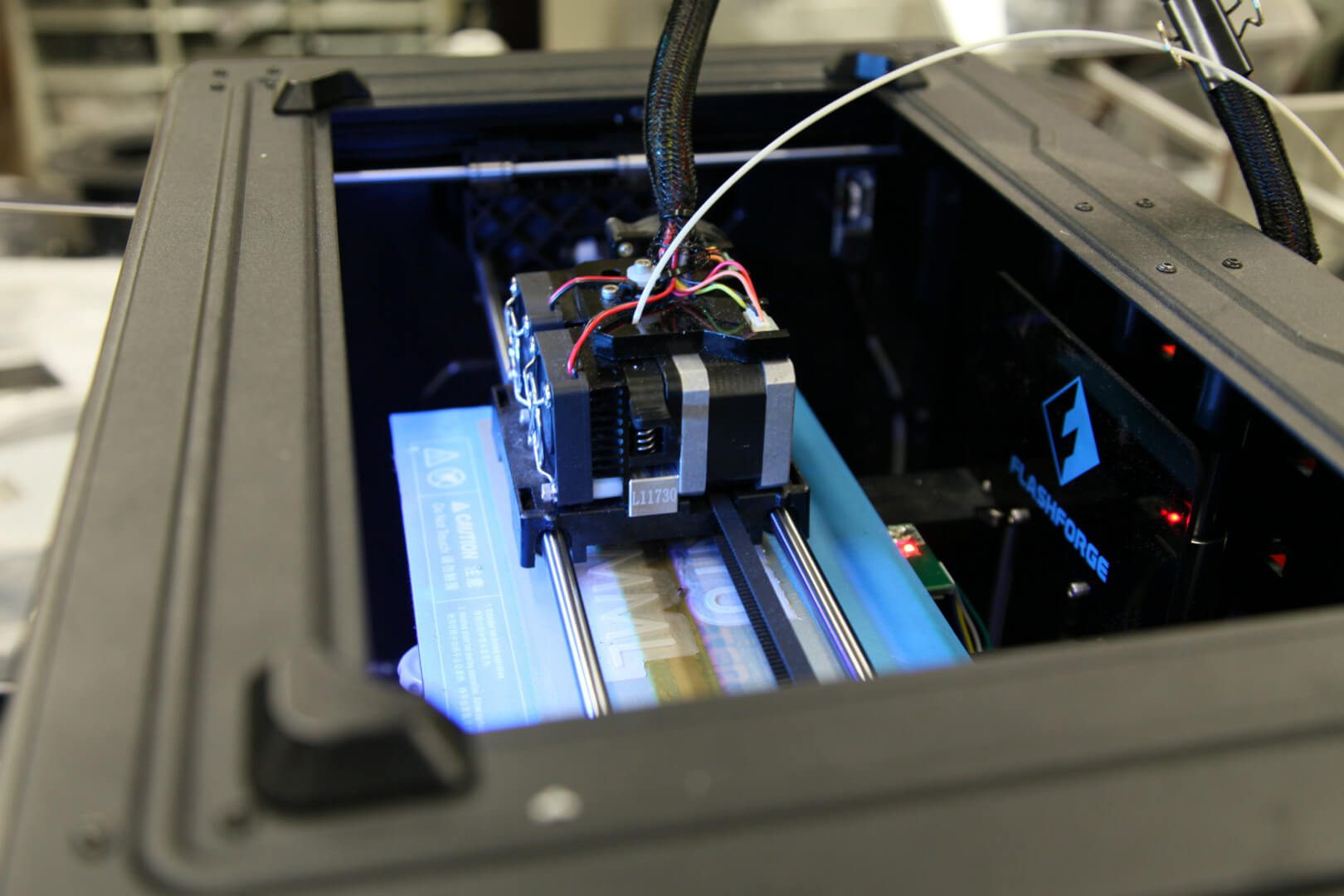

Sail Away on DIY Electric Mini Boat Made with 3D Printing and Laser Cutting

Reading Time: 4 minutesIndustrial designer Josh Tulberg has created the Mini Boat, a 6ft electric boat manufactured with 3D printing and laser cutting technology. You can order a DIY kit from his website Rapid Whale, or build the Mini Boat from scratch using his step-by-step instructions. Meet Josh Tulberg, a Bay Area-based industrial designer and…

-

CEAD Launches Industrial-Scale 3D Printer Tailored for Shipbuilding

Reading Time: 3 minutesThe Netherlands-based additive manufacturing company CEAD is creating an industrial-scale 3D printer that is specifically engineered to help produce parts for ships and other maritime vessels. Whether it be by land, air, or sea, 3D printing is becoming an integral tool across the transportation sector. Although we usually hear tales of how…