Schlagwort: industrial machines

-

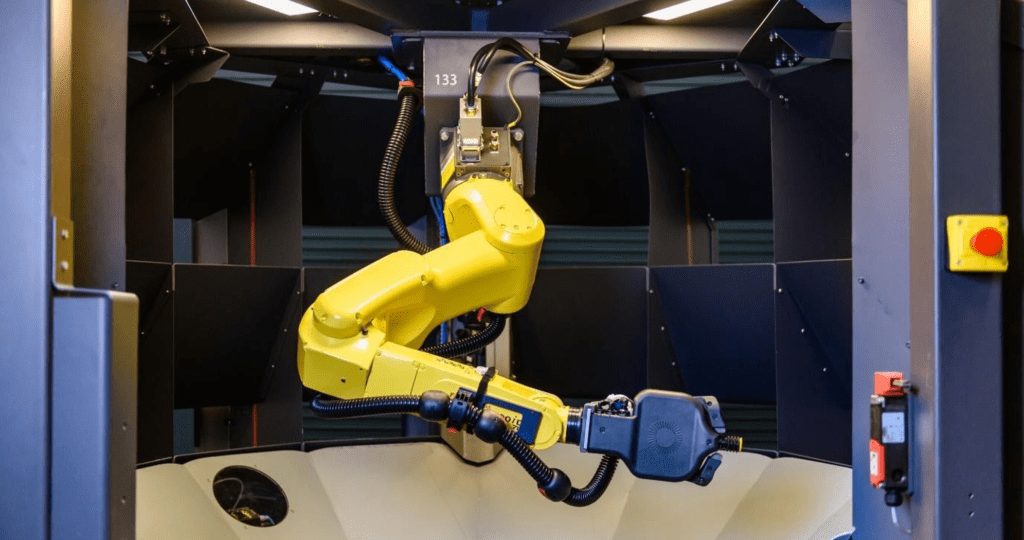

From embedded sensors to advanced intelligence: Driving Industry 4.0 innovation with TinyML

Reading Time: 5 minutesWevolver’s previous article about the Arduino Pro ecosystem outlined how embedded sensors play a key role in transforming machines and automation devices to Cyber Physical Production Systems (CPPS). Using CPPS systems, manufacturers and automation solution providers capture data from the shop floor and use it for optimizations in areas like production schedules,…

-

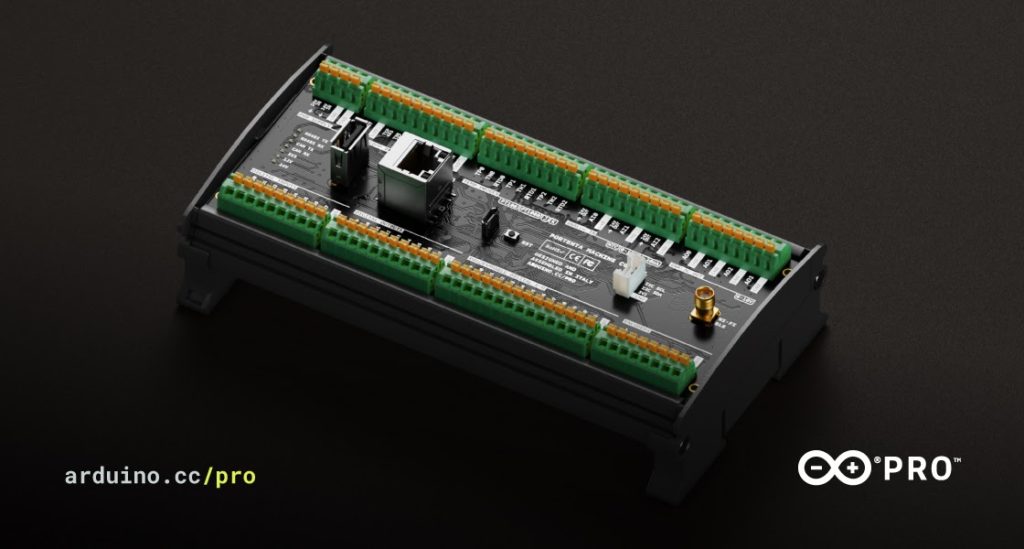

Portenta Machine Control: Add a powerful brain to your machines

Reading Time: 3 minutesArduino Pro is introducing a powerful new member of the Portenta product family, the Portenta Machine Control. It’s a fully-centralized, low-power, industrial control unit able to drive equipment and machinery. Plus, you can program it using the Arduino framework or other embedded development platforms. [youtube https://www.youtube.com/watch?v=2wrBy8qNT60?feature=oembed&w=500&h=281] Thanks to its computing power, the…