Schlagwort: Industrial IoT

-

Simplifying IoT for smarter manufacturing: Join the chat with Arduino, AWS, and Atlas Machine

Reading Time: 2 minutesWe all know that the future of manufacturing lies in IoT — yet the path to adoption can sometimes feel daunting. But what if you could simplify the process and start seeing results quickly? That’s exactly what we’re going to explore in our upcoming Arduino Cloud Café webinar on December 10 at…

-

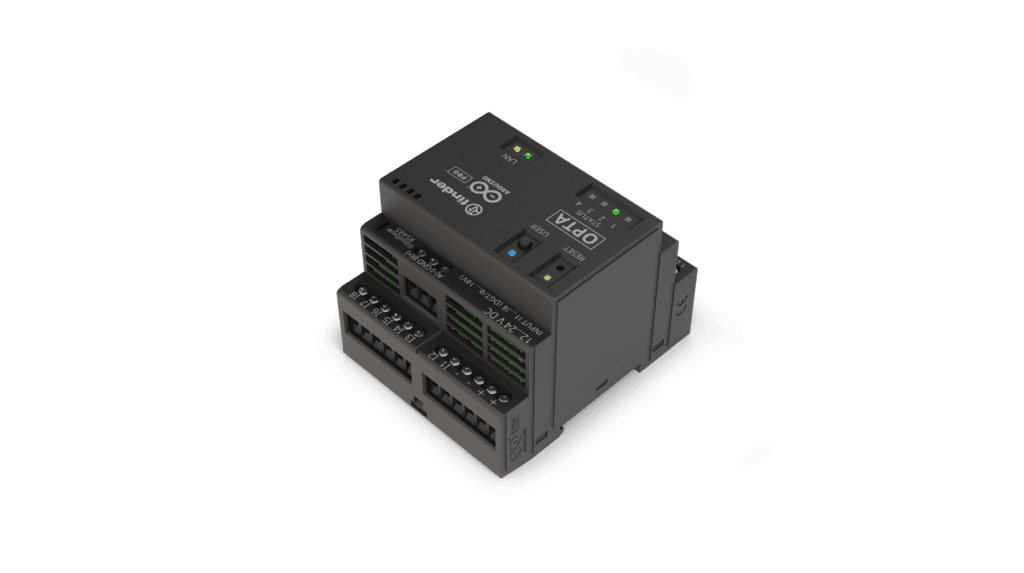

Welcome Opta, our first-ever micro PLC with Industrial IoT capabilities

Reading Time: 2 minutesWe can finally tell you all about the new product we had announced for SPS! Today, we are excited to expand the Arduino Pro range with Opta, our first micro PLC with Industrial IoT capabilities. We designed it specifically with PLC engineers in mind: supporting standard languages including LD (Ladder Logic Diagram)…

-

Industrial IoT anomaly detection on microcontrollers

Reading Time: 2 minutesArduino Team — July 22nd, 2022 Consumer IoT (Internet of Things) devices provide convenience and the consequences of a failure are minimal. But industrial IoT (IIoT) devices monitor complex and expensive machinery. When that machinery fails, it can cost serious money. For that reason, it is important that technicians get alerts as…