Schlagwort: Formlabs

-

Formlabs Form 2 Review – Best Resin 3D Printer of Fall 2018

Reading Time: 12 minutesThe Formlabs Form 2 is our pick for the “Best Resin 3D Printer of Fall 2018”. Check out our Formlabs Form 2 review to find out why. When it comes to 3D printing, FDM printers take all the glory; Ultimakers, Prusas, and Crealitys are talked about constantly. Their machines offer makers, hobbyists,…

-

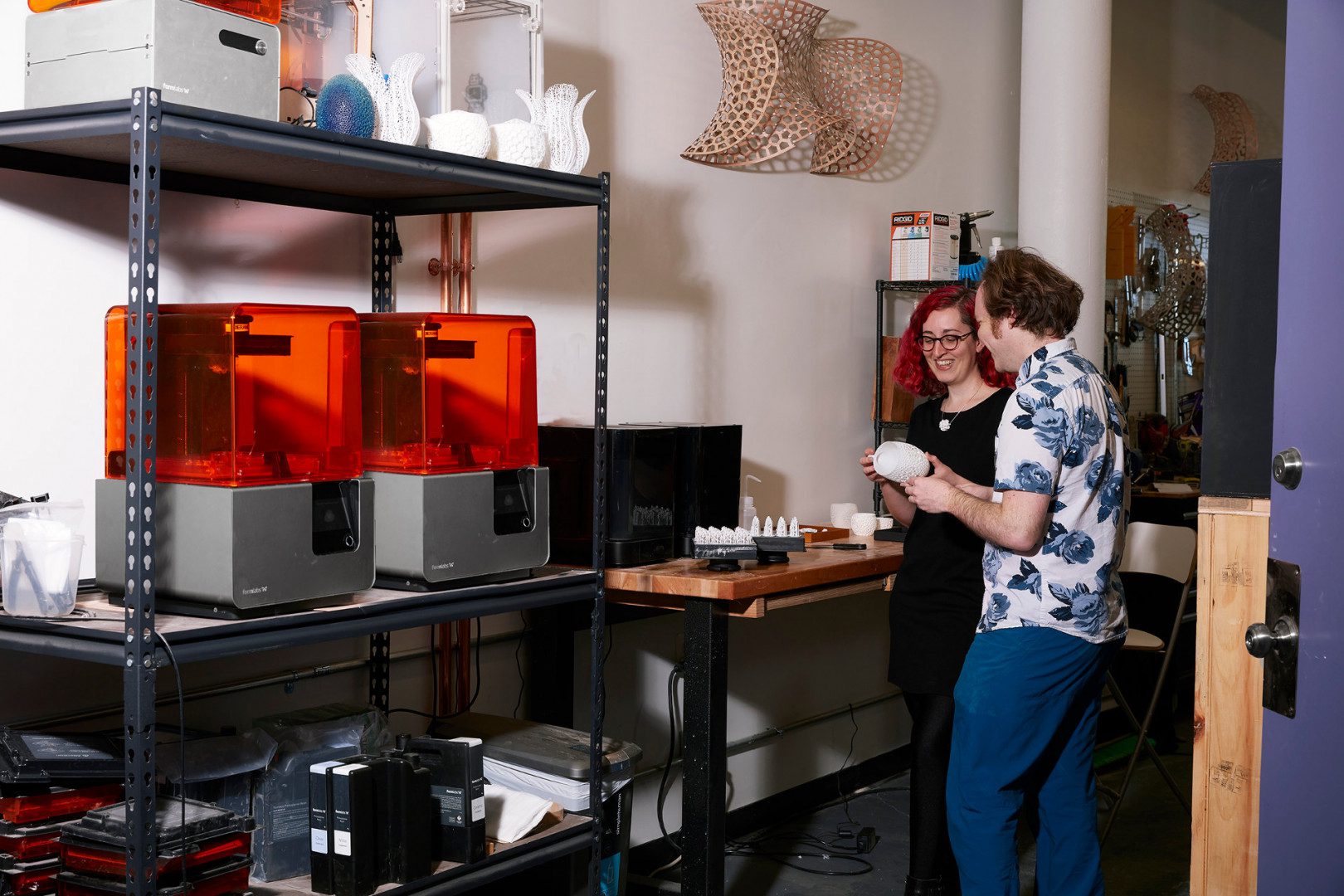

New Ceramic 3D Printed Jewelry from Nervous System

Reading Time: 3 minutesPorifera is a new jewelry collection by Nervous System inspired by the forms of deep-sea glass sponges. It’s 3D printed using an experimental Ceramic Resin from Formlabs. Nervous System is a generative design studio that produces unique collections of art, fashion, jewelry, and housewares. What makes their work so unique? Because it…

-

Experimental Ceramic Resin for the Form 2 Now Available

Reading Time: 2 minutesA new experimental Ceramic Resin is a now available for the Form 2 from Formlabs, making ceramic 3D printing the most affordable and accessible it has ever been for engineers and designers. Stereolithography specialists Formlabs have announced the availability of a special new material for their Form 2 desktop 3D printer. Their…

-

Formlabs Launches ROI Calculator to Assess Costs Of Purchasing a 3D Printer

Reading Time: 3 minutesBusinesses planning to purchase a 3D printer to boost parts production may want to give the new Formlabs ROI calculator a go-to determine long-term costs. When it comes to acquiring a 3D printer for your business, it pays to consider the cost and return on investment (ROI). However, calculating whether the purchase…

-

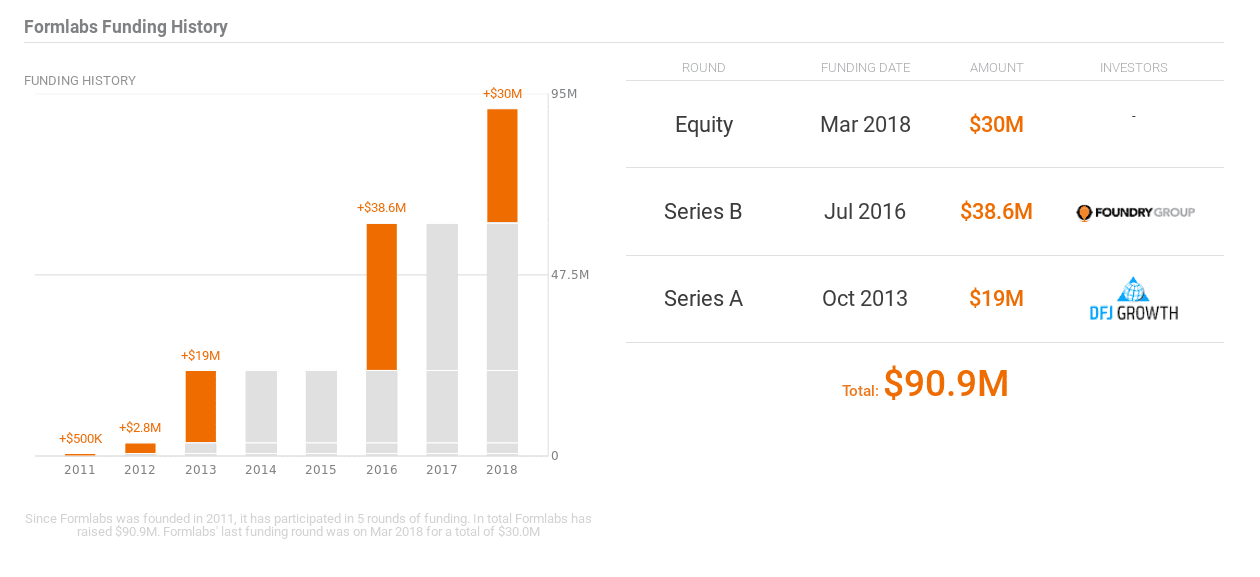

Formlabs Raises $30m in New Equity Funding

Reading Time: 3 minutesWith two major product launches on the horizon, 3D printing startup Formlabs bolster their war-chest with $30m in new equity funding. Market-leading 3D printer manufacturer Formlabs has raised $30 million in new equity funding, according to a document filed with the SEC this week. Together with CEO Maxim Lobovsky, the directors listed…

-

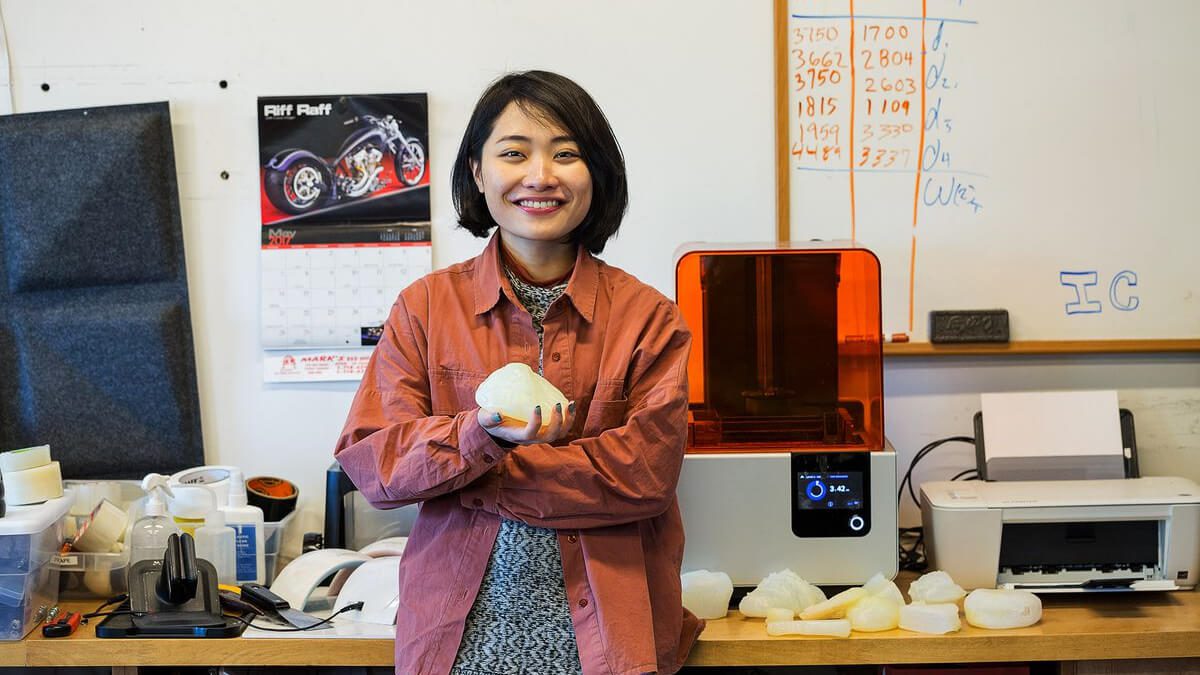

Artist Documents “Ritual of Habits” with 3D Scanning and 3D Printing

Reading Time: 2 minutesRosalie Yu recreates her sweet treats in hyper-realistic detail with a grand project called a Ritual of Habits. She’s creating a virtual reality experience — and a 3D printed facsimile — of 256 desserts (and counting). Art and technology blend together like a fluffy mousse in a 360-degree virtual reality (VR) experience…

-

Formlabs Fuse 1 3D Printer: Review the Facts Here!

Reading Time: < 1 minuteIn June 2017, 3D printer manufacturer Formlabs announced the launch of Fuse 1, the company’s first selective laser sintering (SLS) 3D printer. “When we launched the world’s first desktop stereolithography 3D printer in 2012, Formlabs created new possibilities for designers and engineers to create physical products by giving them access to…

-

Formlabs Showcases Mass Customization, Premieres New Materials

Reading Time: 3 minutesFor the first time, visitors of the Consumers Electronic Show 2018 can take a look at Formlab’s new SLS Fuse 1 3D printer. But there’s more: The company premieres two new materials and showcases interesting new mass customization solutions. At CES 2018, the Formlabs booth will have the Form 2, Fuse 1,…

-

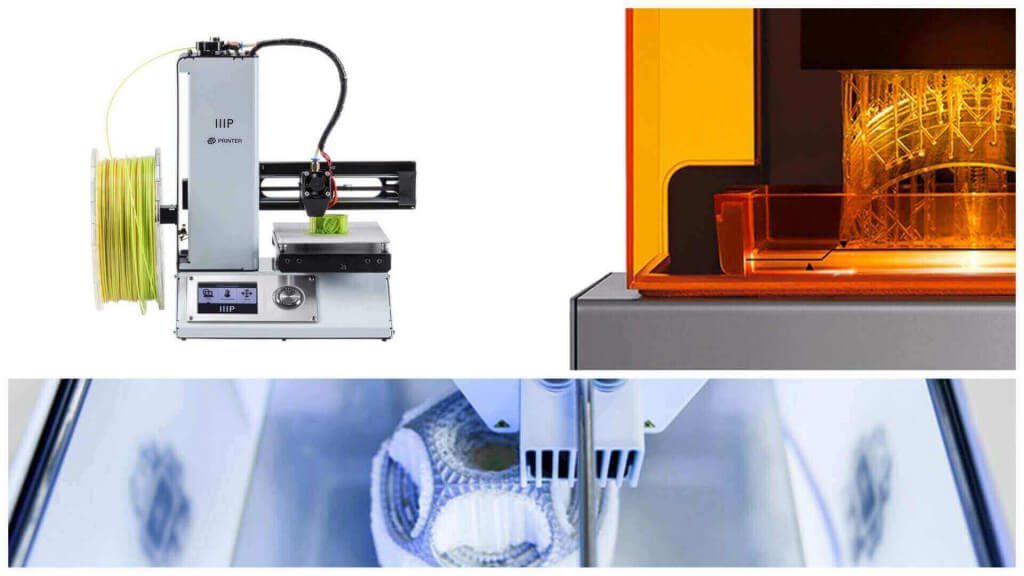

Best 3D Printer Awards 2017 / 2018 – The 12 Best 3D Printers

Reading Time: 4 minutesSelecting the best 3D printer for your needs is not an easy task. We want to make the process it a little bit easier with All3DP’s Best 3D Printer Awards. Finding the Best 3D Printer for Beginners If you are a newcomer to 3D printing, things can get overwhelming. Specifications and terminology…