Schlagwort: FDM

-

Beginner’s Guide on How to Buy a 3D Printer

Reading Time: 5 minutesSo you want to buy a 3D printer? Read this guide before you go shopping to get the best printer for your needs and your budget. You’ve heard so many great things about 3D printers and what you can do with them. There are so many wonderful machines which can make your…

-

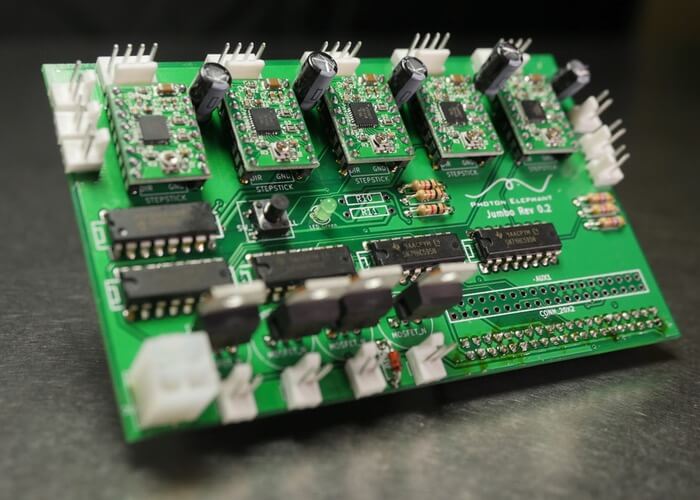

New 3D Printer Firmware Uses Raspberry Pi to Speed Up FDM Printing

Reading Time: 3 minutesGitHub user KevinOConnor has created Klipper, a 3D printer firmware that uses a Raspberry Pi to parse G-code, map out curves, and set accelerations, improving the speed of FDM 3D printing. While one of the key advantages to 3D printing is quick production time, there is still much work to be done when…