Schlagwort: carbon fiber

-

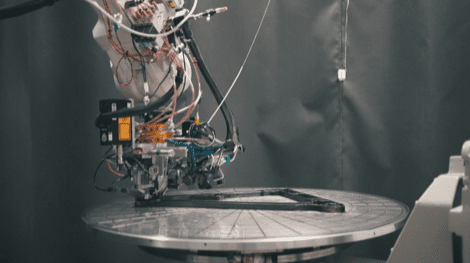

Arevo Boosts Expansion of Carbon Fiber 3D Printing With $12.5 Million Funding Round

Reading Time: 3 minutesThe start-up has launched a unique carbon fiber 3D printing technology that allows for enhanced scalability. Through the latest cash injection, it hopes to commercialize the technology more quickly. Carbon fiber 3D printing is set to become a dominant trend in additive manufacturing over the next few years. This is driven in…

-

CEAD Launches Industrial-Scale 3D Printer Tailored for Shipbuilding

Reading Time: 3 minutesThe Netherlands-based additive manufacturing company CEAD is creating an industrial-scale 3D printer that is specifically engineered to help produce parts for ships and other maritime vessels. Whether it be by land, air, or sea, 3D printing is becoming an integral tool across the transportation sector. Although we usually hear tales of how…