Schlagwort: Bicycle

-

Celebrate World Bicycle Day with these Arduino-powered bike projects

Reading Time: 7 minutesCycling is a great way to spend time outdoors while simultaneously getting exercise and even as a mode of efficient transportation. And in the last few years due to the recent proliferation of e-bikes on the market and the pandemic, there has been an explosion in the number of people wanting to…

-

Shift4Me is an automatic bicycle shifter

Reading Time: < 1 minuteShift4Me is an automatic bicycle shifter Arduino Team — September 9th, 2020 These days many of us are turning to bicycling for fun and exercise. While some may enjoy being able to change up the resistance and pedal speed by shifting, if you would instead prefer to be in the ideal…

-

Upgrade Your Ride with a 3D Printed Airless Bicycle Tire?

Reading Time: 3 minutesTo showcase their new flexible filament, 3D printer manufacturer BigRep fabricated a 3D printed airless bicycle tire and took it for a spin on the streets of Berlin. Don’t Miss: BigRep Launches New Pro Flex Filament for 3D Printing Summer’s here! It’s time to dust off your trusty bicycle and take it…

-

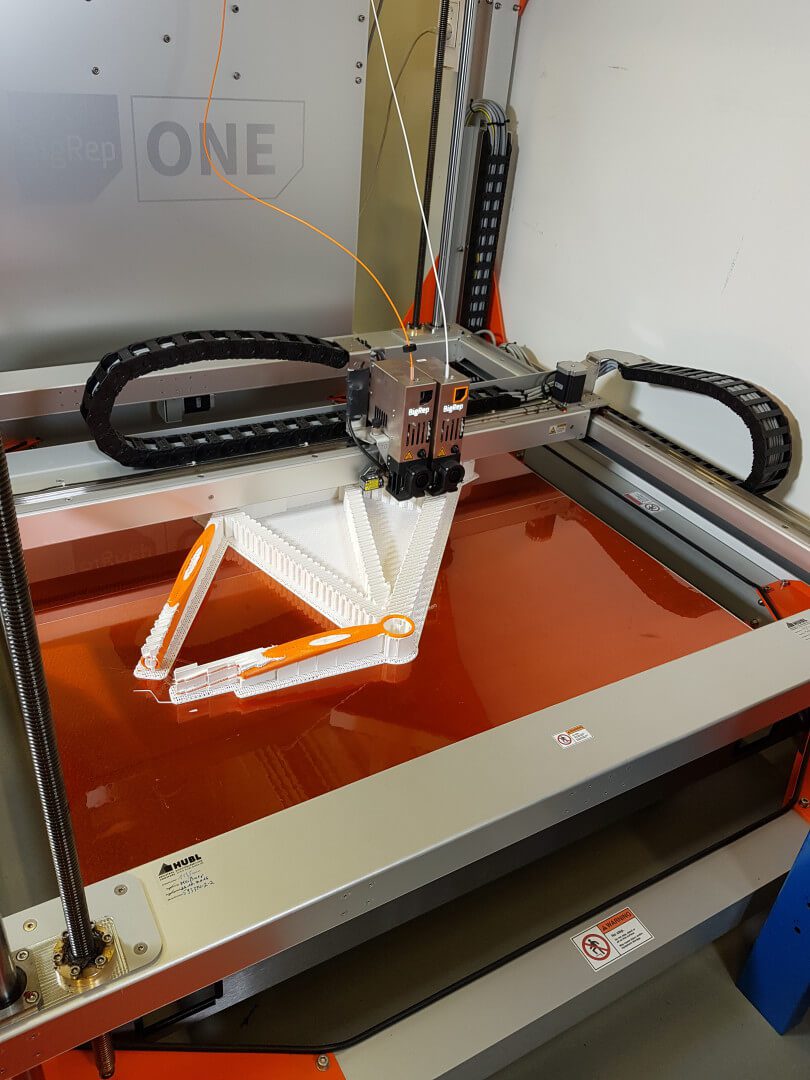

Danish Engineering Students Use BigRep ONE 3D Printer to Create Functional Bicycle Design

Reading Time: 4 minutesMechanical engineering students from the Aalborg University Esbjerg have used a BigRep ONE to 3D print a functional bike frame in one piece. PhD doctorate Peter Riddersholm Lauridsen shares an inside look at this project, and explains how 3D printing enables students to hone their engineering skills. In universities across the world, 3D printing…