Schlagwort: Autodesk

-

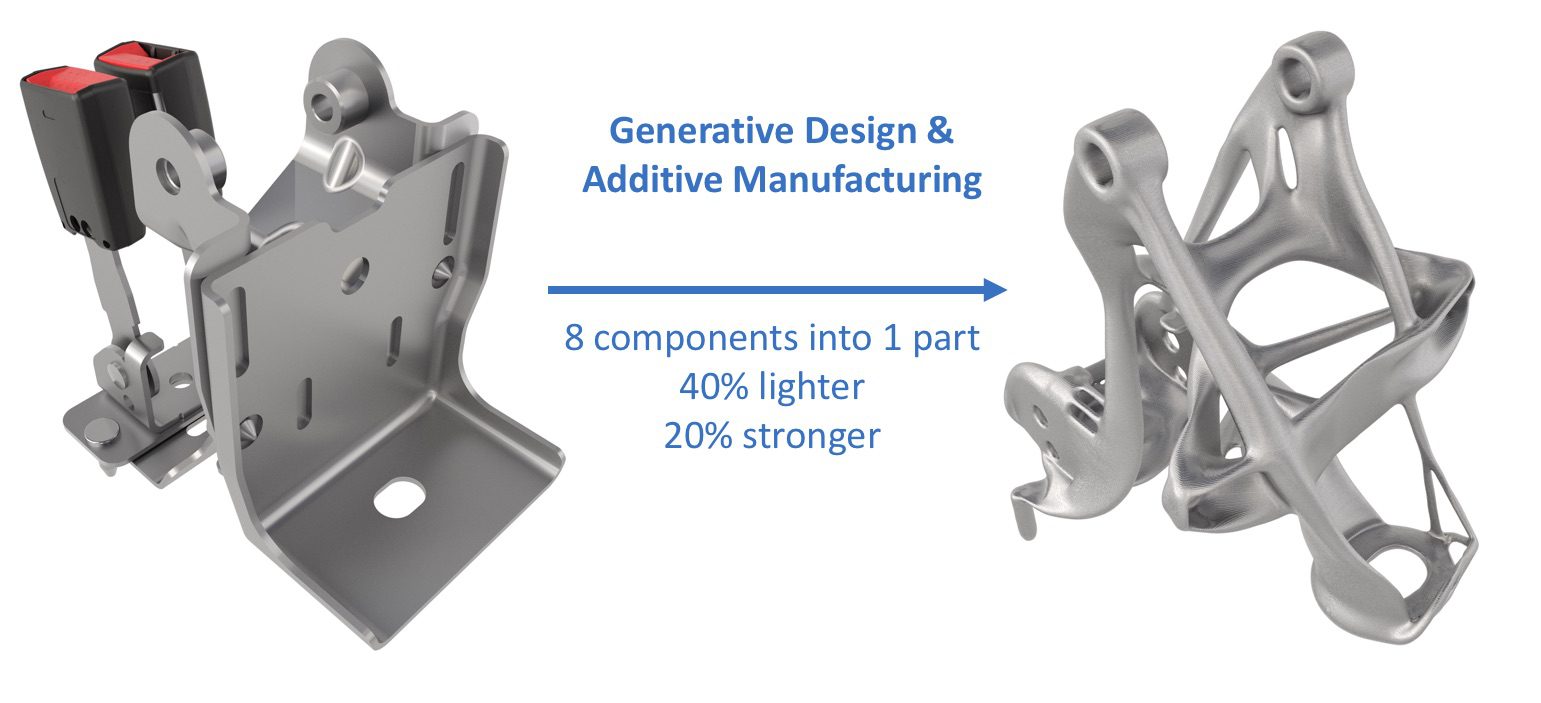

GM and Autodesk Using Additive Manufacturing for Lighter Vehicles

Reading Time: 3 minutesGM is using Autodesk’s generative design technology and additive manufacturing to fabricate lighter automotive parts; this seat bracket is 40% lighter and 20% stronger than its predecessor. General Motors is using generative design software by Autodesk to develop the next generation of lightweight vehicles. According to the automaker, the new technology will…

-

Autodesk Supporting Hip Hop Architecture Camps for Second Year

Reading Time: 3 minutesNow in its second year, Autodesk and the Urban Arts Collective continue their collaboration on Hip Hop Architecture Camps, inviting local middle and high school students to re-imagine their communities and introduce STEAM education through the lens of hip hop culture. The 3D printing industry isn’t the only place that’s suffering from…