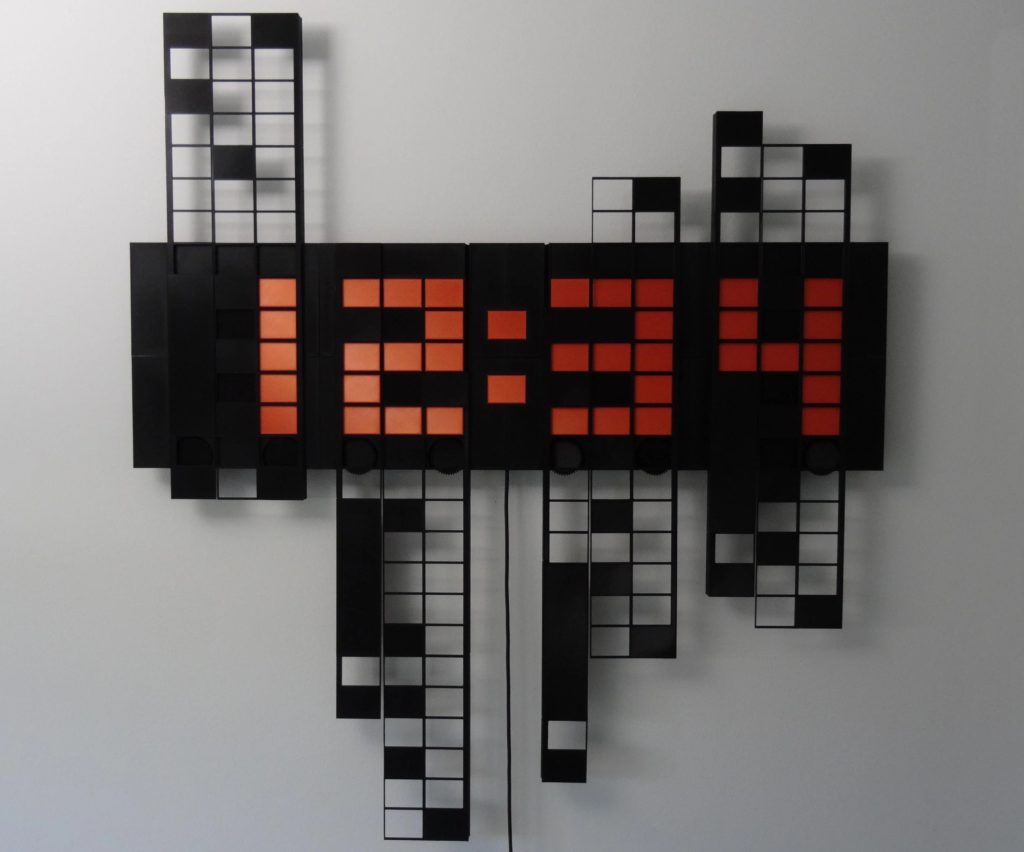

You can build a simple and accurate clock with any Arduino board, an RTC (real-time clock) module, and a four-digit seven-segment display. But if you want to be inspired by a more unique design, check out Hans Andersson’s Time Slider.

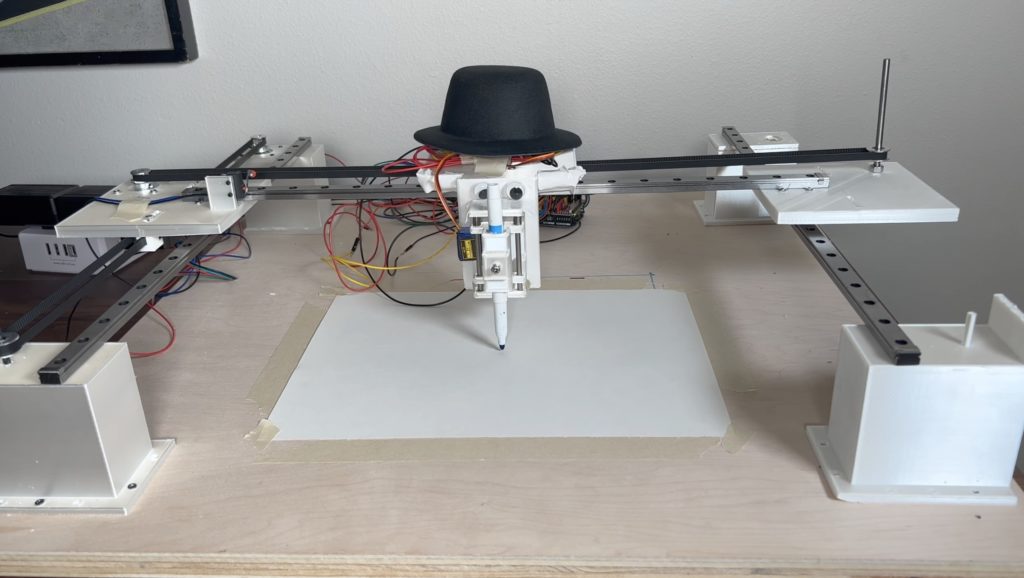

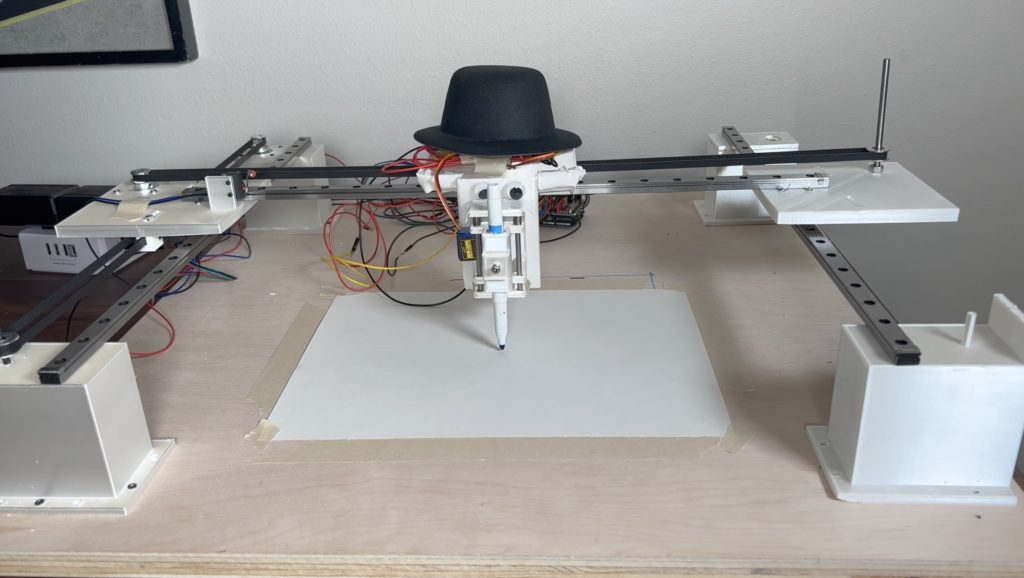

This clever clock features four sliders — one for each digit of the time. Those sliders are 3D-printed frames which contain grids of “pixels” that are either open to make the backing visible, or closed to be black. They move up and down to whatever position is necessary to show the pixels necessary to form a numeric digit. The great thing about this design (aside from the interesting aesthetic), is that it is easy to scale up or down to whatever size the user wants.

The hardware components for this project include an Arduino Mega 2560 board, a DS3231 RTC module, eight ULN2003 motor drivers with 28BYJ-48 pancake stepper motors, wires, and a power supply. All of the mechanical parts are 3D-printable. Two stepper motors drive each slider to ensure smooth operation. There are not any buttons to set the time, so the user must configure that in the included sketch and then immediately upload the code during setup.

The post Time Slider is an interesting spin on clock design appeared first on Arduino Blog.

Website: LINK