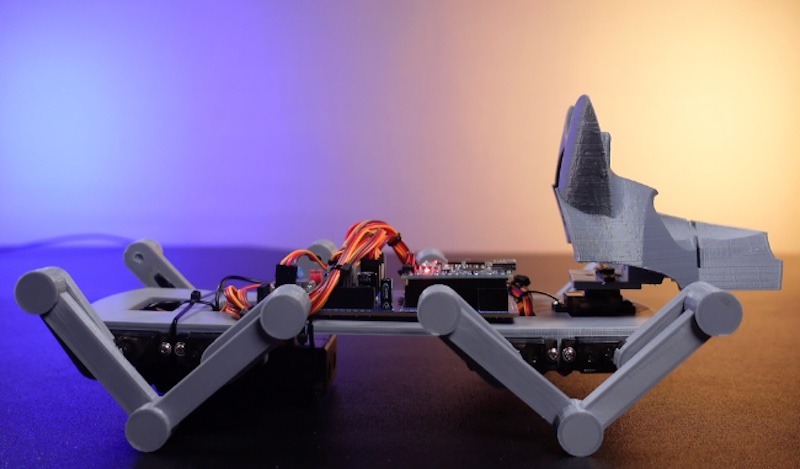

Racing “video games” can be incredibly realistic these days, with every facet of the car’s physics and their interaction with the asphalt programmed in. Those racing sims could provide a completely immersive experience — if the player wasn’t sitting on a motionless couch using a controller that doesn’t resemble a car’s steering wheel in the slightest. To rectify that issue, high school student Pranshu Agnihotri built his dream racing wheel.

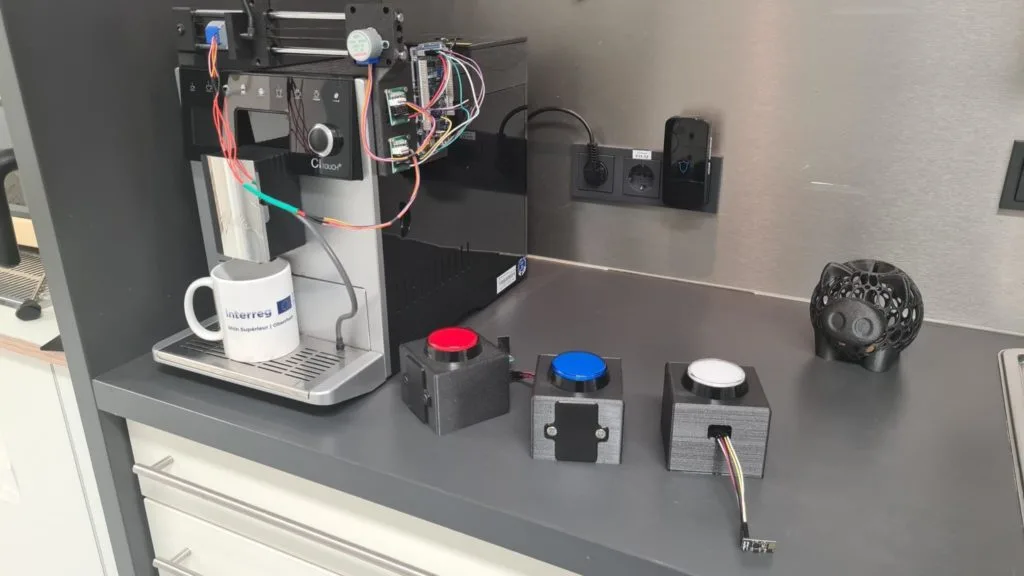

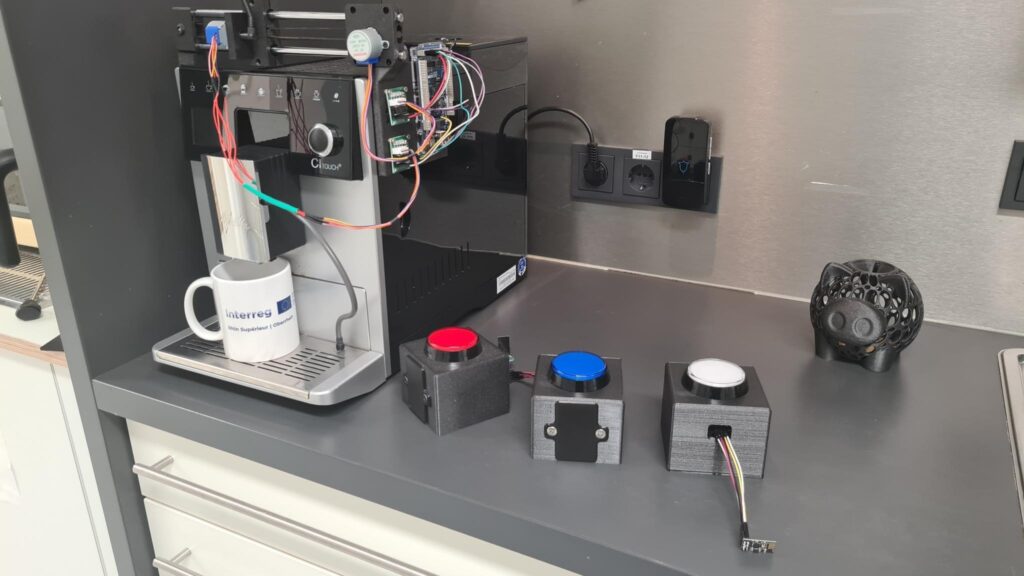

Agnihotri tackled this project for a senior project in his Principles of Engineering class at Irvington High School. Its purpose is to provide a more realistic interface for racing games and sims. It doesn’t have any force feedback capabilities, but it will work with any PC game thanks to the Arduino that lets the user easily rebind controls. Those can even emulate keyboard and mouse inputs for games that weren’t designed for use with steering wheels.

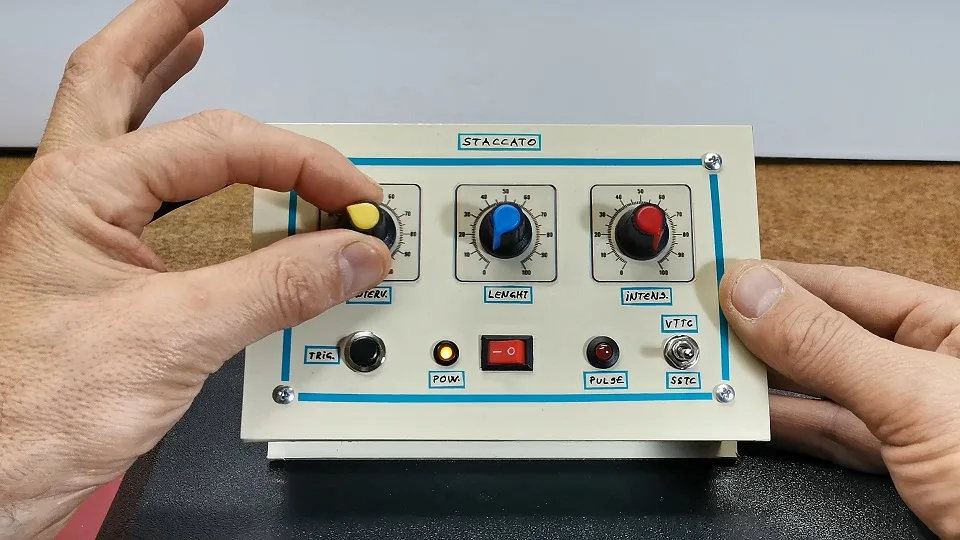

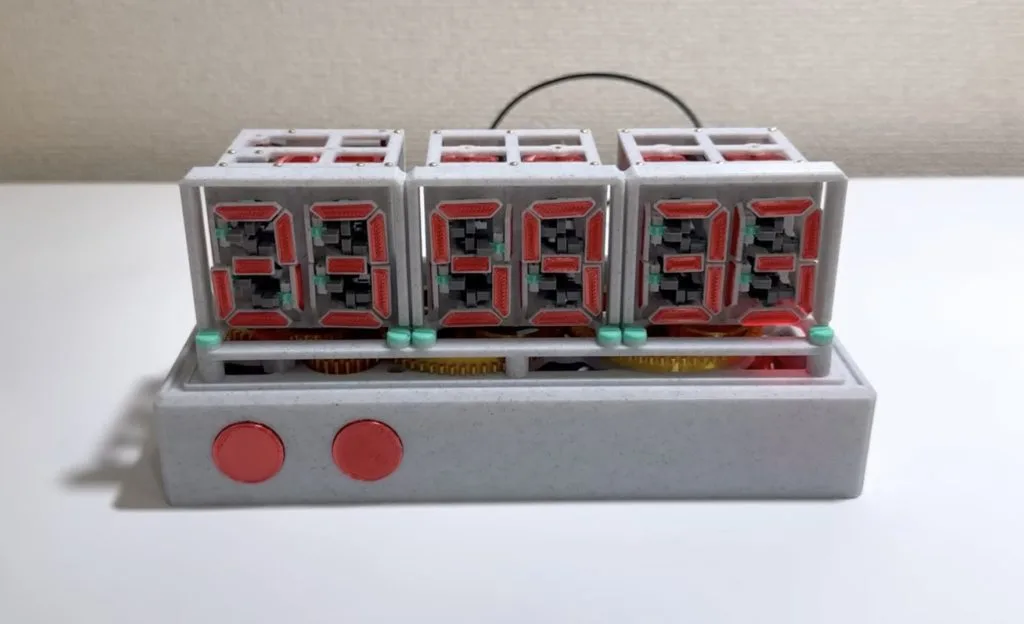

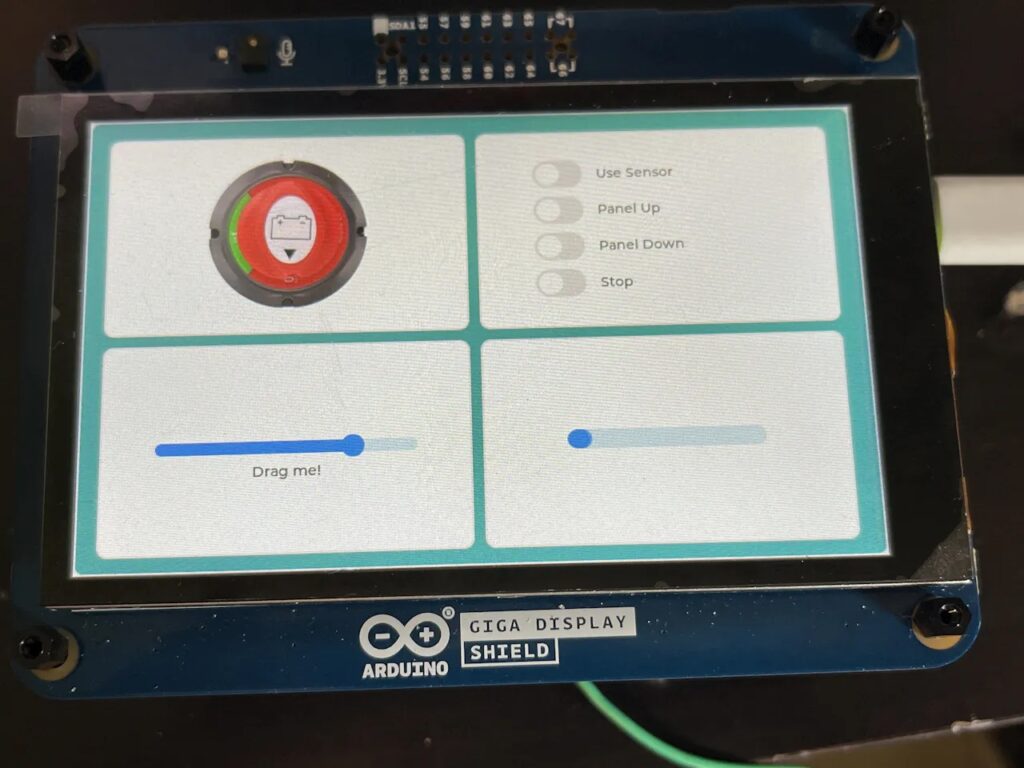

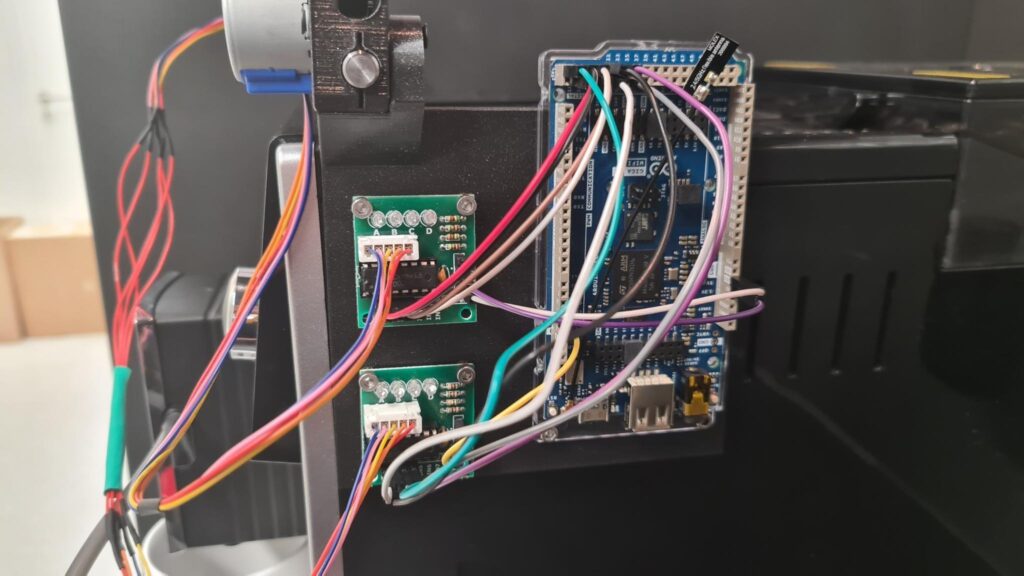

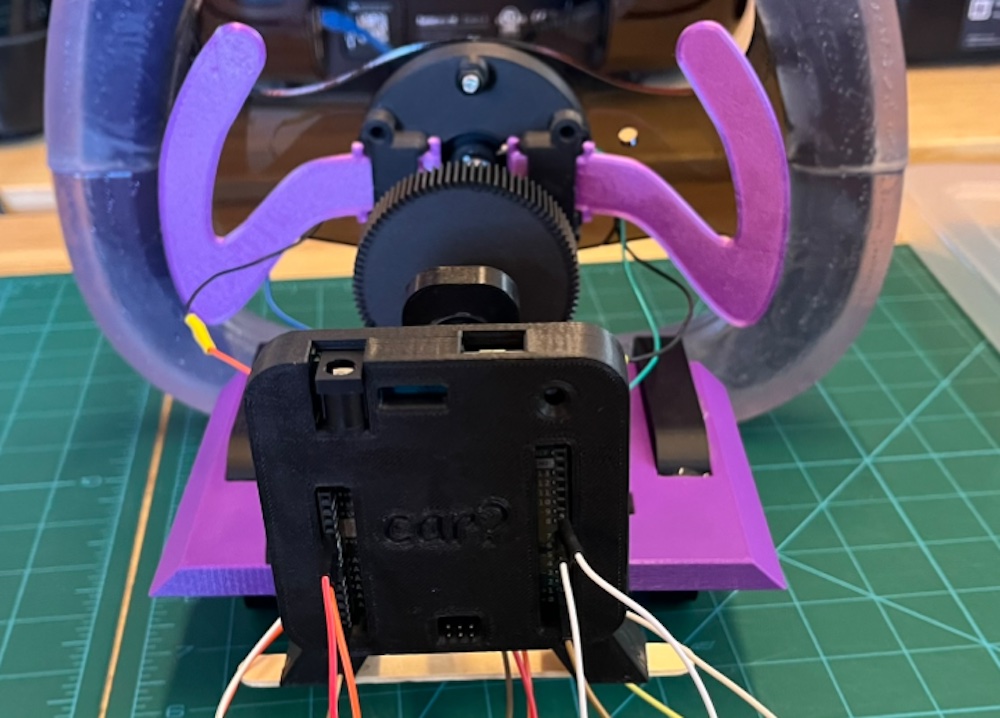

The brain is an Arduino Leonardo, which Agnihotri chose for its Microchip ATmega32U4 microcontroller. That is configurable as a standard USB HID, so any computer will recognize its inputs without any special drivers or software. The steering wheel and electronics enclosure were 3D-printed in exactly the shape Agnihotri wanted. An M8 threaded shaft acts as the steering column. A potentiometer provides steering angle input, while limit switches detect when the player presses the paddle shifters. The Arduino reads those inputs, then sends out the corresponding gamepad, keyboard, or mouse commands via USB.

We have to assume that Agnihotri aced this assignment, and now he has an awesome steering wheel to race with.

The post High school student builds his dream racing wheel appeared first on Arduino Blog.

Website: LINK