Schlagwort: Anomaly Detection

-

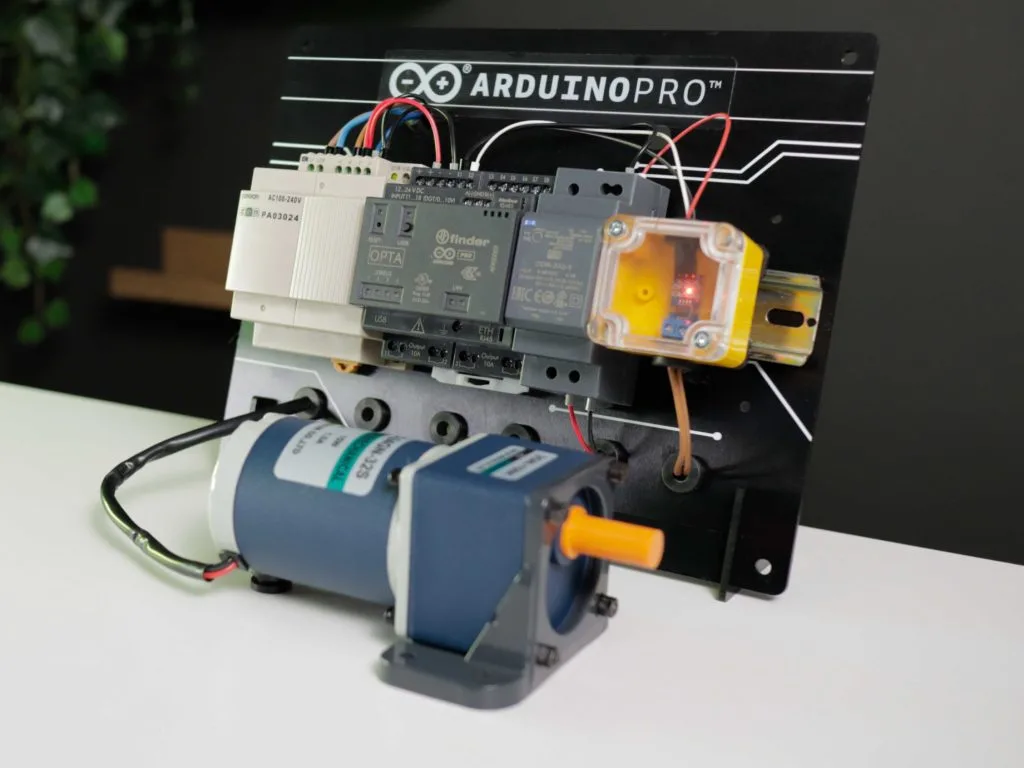

Ensure DC motor performance with anomaly detection based on energy monitoring

Reading Time: 5 minutes[youtube https://www.youtube.com/watch?v=jskIyHzcH7A?feature=oembed&w=500&h=281] The challenge Optimizing manufacturing processes is a requirement in any industry today, with electricity consumption in particular representing a major concern due to increased costs and instability. Analyzing energy use has therefore become a widespread need – and one that can also lead to early identification of anomalies and predictive…

-

Predicting potential motor failures just using sound

Reading Time: 2 minutesNearly every manufacturer uses a machine at some point in their process, and each of those machines is almost guaranteed to contain at least one motor. In order to maintain uptime and efficiency, these motors must always work correctly, as even a small breakdown can lead to disastrous effects. Predictive maintenance aims…

-

Industrial IoT anomaly detection on microcontrollers

Reading Time: 2 minutesArduino Team — July 22nd, 2022 Consumer IoT (Internet of Things) devices provide convenience and the consequences of a failure are minimal. But industrial IoT (IIoT) devices monitor complex and expensive machinery. When that machinery fails, it can cost serious money. For that reason, it is important that technicians get alerts as…

-

VenTTracker is an anomaly detection system for windows to help ensure proper ventilation

Reading Time: 2 minutesArduino Team — August 19th, 2021 Within an industrial setting, being able to determine if and/or when a machine malfunctions is vital to maintaining safety and uptime. This challenge is what prompted a maker who goes by javagoza on element14 to enter into their Design for a Cause 2021 contest with his device, which he calls…