Schlagwort: 3D Printing Metal

-

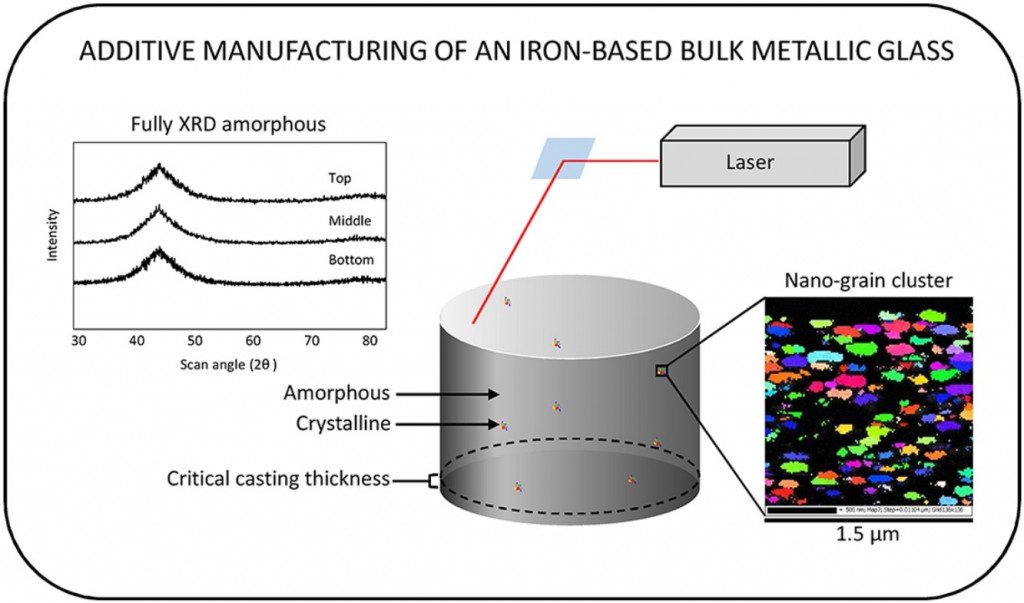

Researchers Reveal Method to 3D Print Metallic Glass Alloys in Bulk

Reading Time: 3 minutesMaterials Science and Engineering researchers at North Carolina State University recently detailed their method to produce large amounts of metallic glass alloys using 3D printing. The development could lead to better efficiency in electric motors and tougher materials and structures. Researchers at the Material Science and Engineering department at North Carolina State…

-

Iro3D is Developing a Desktop Metal 3D Printer That Only Costs $5,000

Reading Time: 3 minutesThe Seattle-based company Iro3D is developing a desktop metal 3D printer that will cost just $5,000. The printer is reportedly capable of producing strong, high carbon steel objects. It was recently debuted on Joel Telling’s “3D Printing Nerd” YouTube channel. Nowadays, it’s relatively easy and inexpensive to get your hands on a decent…