Schlagwort: 3D Printing in Space

-

ESA Now Testing a Prototype Microgravity 3D Printer

Reading Time: 3 minutesThe European Space Agency (ESA) is testing a 3D printer designed to work under microgravity and fabricate with engineering polymers featuring high end mechanical and thermal properties. A prototype 3D printer capable of printing in microgravity has been handed over to the European Space Agency (ESA) for use on the International Space…

-

Made In Space Receives NASA’s “Small Business Prime Contractor of the Year” Award

Reading Time: 2 minutesNASA’s Johnson Space Center this week awarded Made In Space, the space manufacturing company, with the Small Business Prime Contractor of the Year Award for performing well on every NASA contract. Made In Space is responsible for the Additive Manufacturing Facility which was sent into orbit in March 2016. As a result of their hard work,…

-

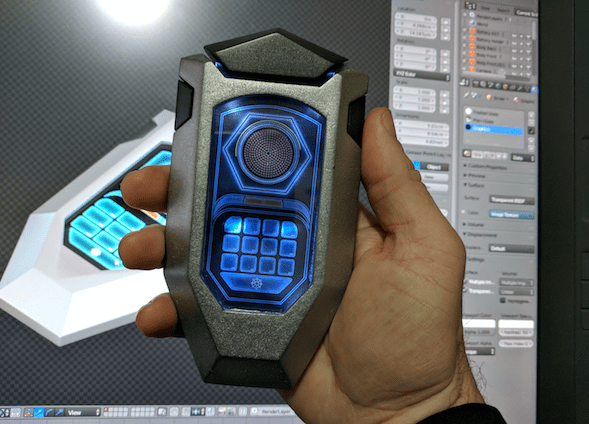

3D Print Your Own Tricorder from the TV Series “The Orville”

Reading Time: 3 minutesA Reddit user 3D modeled and printed a replica comscanner from Star Trek inspired TV series The Orville without having anything to base his dimensions on other than screenshots from the show. Any fans of The Orville, the American sci-fi comedy-drama inspired by Star Trek, will know the difficulty of procuring memorabilia. The…

-

Austiwawa 3D Prints and Launches CO2-Powered Rockets with Onboard Camera

Reading Time: 3 minutesA popular YouTuber named Austin used 3D printing to create rockets that launch with compressed CO2. He tried to modify the rockets to include an onboard camera, and his entire trial and error process was captured on video. Not only is 3D printing technology being applied to industries across the world, it’s…