Schlagwort: 3D printing in science

-

3D Printed RoboToads Help Explain Mating Habits

Reading Time: 3 minutesA team of behavioral ecologists out of the University of Windsor, Canada, studies the mating habits of color-changing toads in Costa Rica using RoboToads — 3D printed, motorized replicas. As most of us know, attracting a mate is no simple task. How do you bring attention to yourself without being too obvious?…

-

Custom-Shaped Explosives for US Navy 3D Printed on HP 3D Printers

Reading Time: 3 minutesWe could soon see custom-shaped 3D printed explosives on the battlefield. A Tennessee-based consultancy, called E&G Associates, is aiding the US Navy in the creation of such devices. E&G Associates is a Tennessee-based consultancy which advises companies on how to work with and handle bulk solids. They have the tagline “we fix powders”…

-

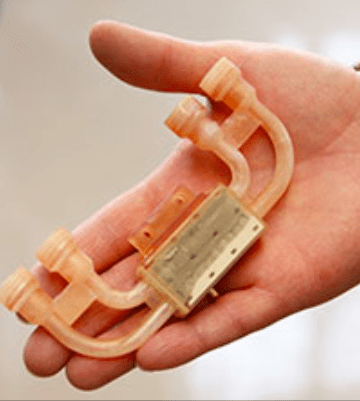

Temple University Professor Develops 3D Printed Bandages Made From Soy

Reading Time: 3 minutesScientists from Temple University in Philadelphia created a prototype for an “electrospun healing” device which uses soy protein and water to print personalized bandages directly onto a patient’s skin. Soon, every household may have a handheld 3D printer which prints personalized bandages directly onto a wound. The printed bandage would allow a patient moves…

-

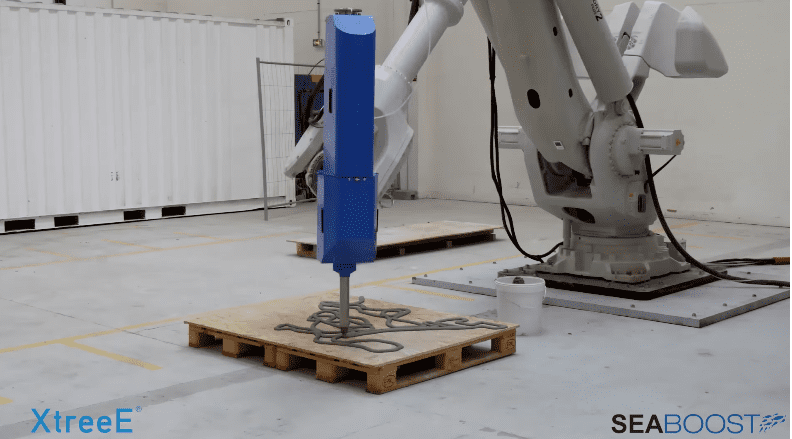

3D Printed Reefs May Offer Hope to Restore Dying Coral Reefs Worldwide

Reading Time: 3 minutes3D printing may provide a sustainable solution to the current crisis of coral reef death globally. Population growth and the environmental burden that accompanies it has taken a serious toll on the Australian Great Barrier Reef and many other coral reefs over the last few years. Rising temperatures across the reefs have…

-

How 3D Printing Helps You to Get a Better Fridge

Reading Time: 3 minutesCaloriSMART is an advanced model system that uses magnetocaloric materials to achieve refrigeration cooling. The system, that even could help you get a better fridge, was designed by researchers at the U.S. Department of Energy’s Ames Laboratory. Gas compression refrigeration is a 100-year-old energy inefficient technology which needs updating. Researchers from the U.S. Department of Energy’s…

-

Berkeley Scientists 3D Print Liquid Structures Within Liquids

Reading Time: 3 minutesSounds like Sci-fi: Berkeley Scientists 3D printed entirely liquid materials that are flexible, stretchable, and could power electronics. They also could be used for chemical synthesis. Researchers at the Department of Energy’s Lawrence Berkeley National Laboratory have figured out a way to print 3D structures that are made entirely of liquids. They…

-

Can the 3D Printed Synthetic Pollenizer Help the Bee Population?

Reading Time: 3 minutesA conceptual 3D printed idea called the Synthetic Pollenizer by an artist from Brisbane aims to keep bee populations alive and thriving. A whopping third of our food sources rely on bees. And yet, it’s no secret that bees are in danger of dying out. The varroa mite and still-in-use pesticides called neonicotinoids have…

-

3D Scanning and Printing Tasmanian Tiger Joeys to Give Insight into Extinct Animal

Reading Time: 3 minutesResearchers have taken CT scans of preserved Tasmanian tiger joeys to help give them a better insight into the extinct animal and learn about the early development phases of the marsupials. Tasmanian tigers were driven to extinction by hunters. Sadly, the last living Tasmanian tiger died in Hobart Zoo in 1936. However, 13 ethanol-preserved…