Schlagwort: 3D Printer Reviews

-

Formlabs Form 2 Review – Best Resin 3D Printer of Fall 2018

Reading Time: 12 minutesThe Formlabs Form 2 is our pick for the “Best Resin 3D Printer of Fall 2018”. Check out our Formlabs Form 2 review to find out why. When it comes to 3D printing, FDM printers take all the glory; Ultimakers, Prusas, and Crealitys are talked about constantly. Their machines offer makers, hobbyists,…

-

JGAurora A5 3D Printer: Review the Facts Here!

Reading Time: 2 minutesThe JGAurora A5 is a big machine – if you want to add it to your workshop, you’ll definitely need to clear some space. The printer itself is capable of producing prints as big as 305 x 305 x 320 mm, which puts it in the range of the popular Creality CR-10 (300 x…

-

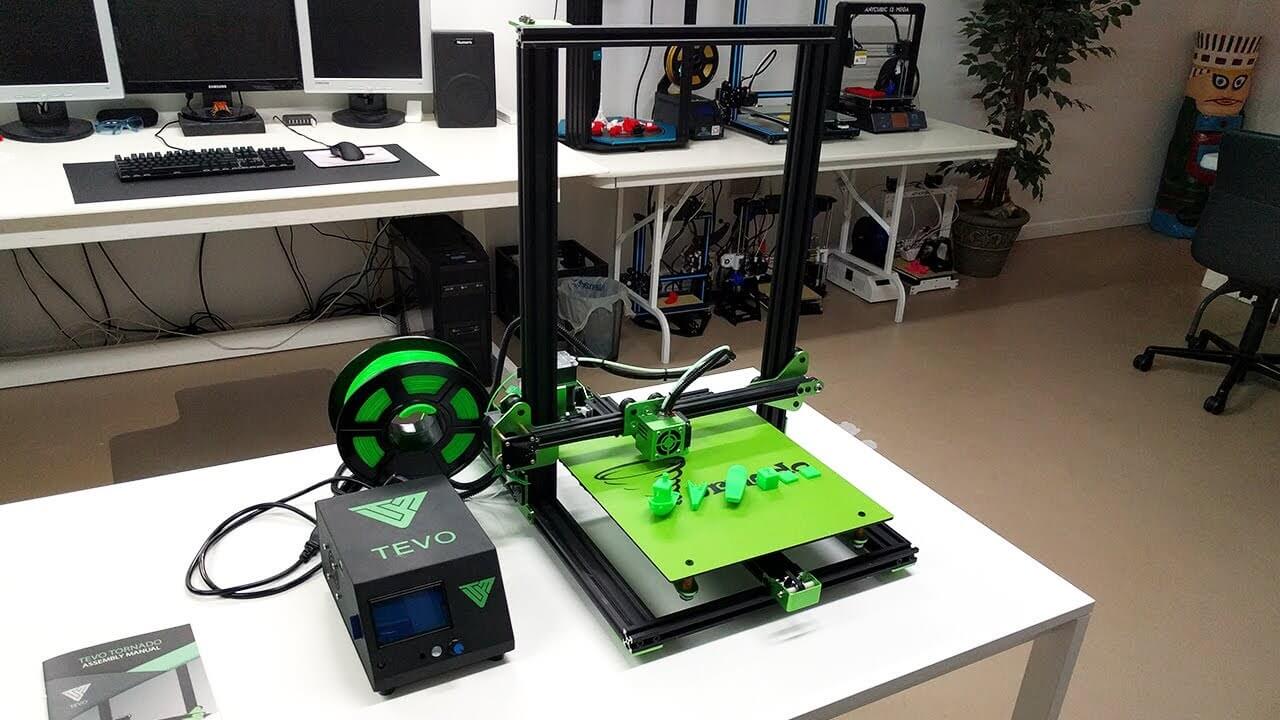

TEVO Tornado 3D Printer: Review the Facts Here

Reading Time: 2 minutesGenerally speaking, the most appealing feature of the TEVO Tornado 3D printer is the 300 X 300 X 400 mm build size, which for around $350 seems like a bargain in-and-of-itself. Pair that with a 50 micron minimum layer thickness and a 150 mm/s print speed, and this 3D printer sounds pretty decent.…

-

Tronxy X1 3D Printer: Review the Facts Here!

Reading Time: 2 minutesThere are a few features that make the Tronxy X1 3D printer a viable option for consumers on a budget. However, the most enchanting perk of this 3D printer is the exceptionally low price tag. It can regularly be found on retail websites like GearBest and AliExpress for under $150. This 3D…

-

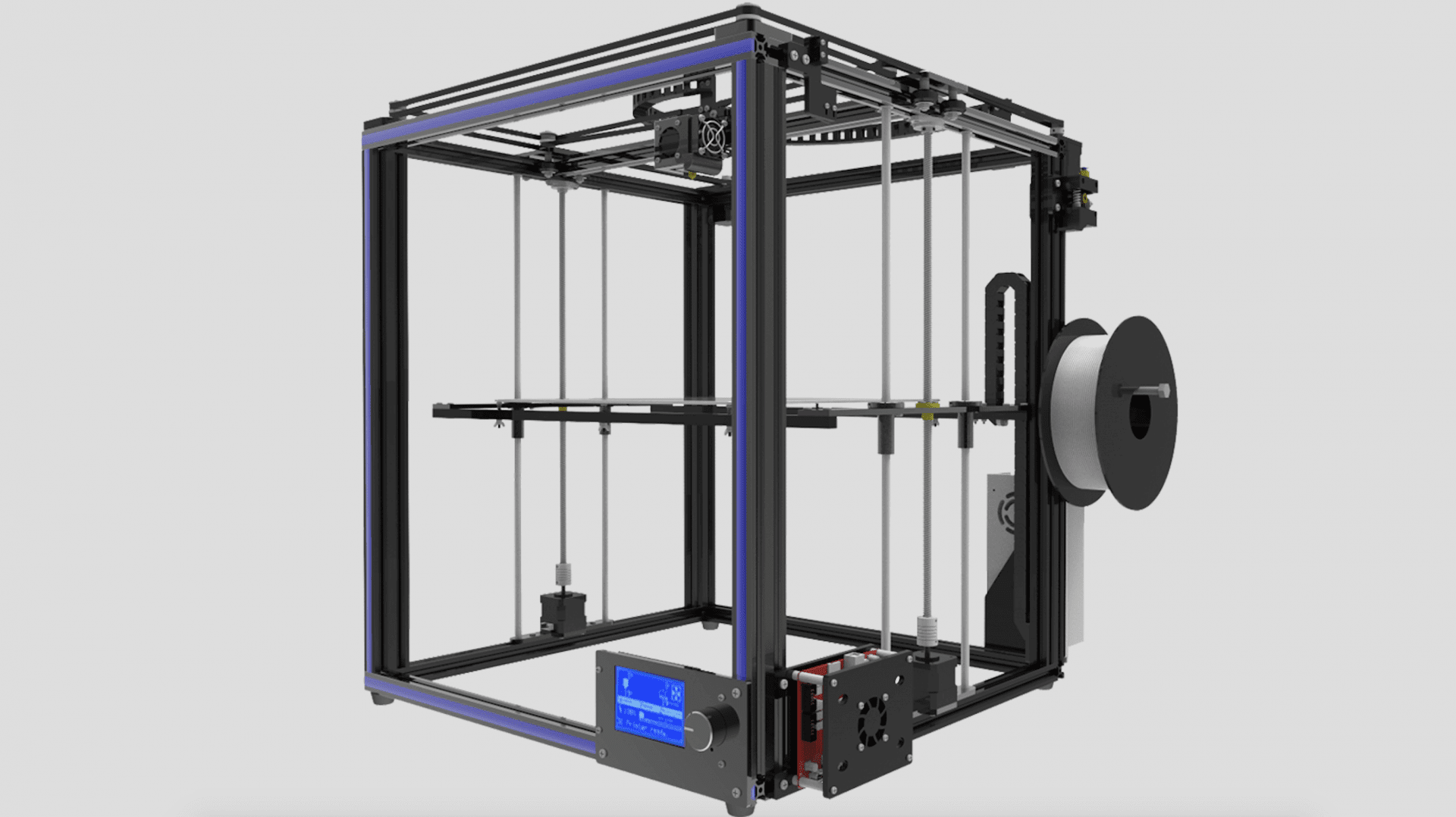

TronXY X5S 3D Printer: Review the Facts Here!

Reading Time: < 1 minuteThe TronXY X5S is one of the new 3D printers kits which seems to hit a sweet spot with customers worldwide. TheTronXY X5S is the bigger brother of the TronXY X3S and has overtaken it in popularity. Since early 2018, it has become one of the best-selling 3D printers on stores like Gearbest…

-

Lulzbot TAZ 6 Review: The Best Large Format 3D Printer

Reading Time: 11 minutesThe Lulzbot TAZ 6 comes assembled in a sizable box that features its name in big, bold letters alongside the company’s iconic logo. This triumphant choice in packaging fits the printer’s large build volume and open source bravado that Aleph Objects prides itself on. Right away, unpacking this printer reveals a number…

-

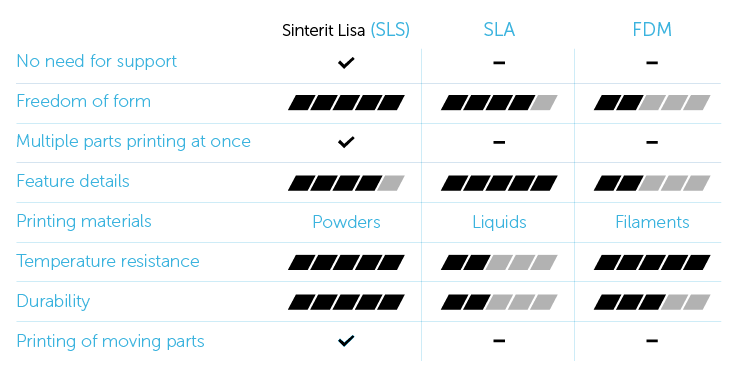

Sinterit Lisa Desktop SLS 3D Printer: Review the Facts!

Reading Time: 3 minutesWhat makes the Sinterit Lisa so unique is the successful integration of SLS technology into a compact and easy to use machine. Generally speaking, there are a number of advantages that SLS technology offers over FDM and SLA, such as the ability to print without supports, nest multiple objects in a single…

-

Beginner’s Guide on How to Buy a 3D Printer

Reading Time: 5 minutesSo you want to buy a 3D printer? Read this guide before you go shopping to get the best printer for your needs and your budget. You’ve heard so many great things about 3D printers and what you can do with them. There are so many wonderful machines which can make your…