Schlagwort: 3D printed prosthetics

-

Thermoplastic Carbon Fiber 3D Printed Prosthetic Sockets May Be Strongest Yet

Reading Time: 3 minutesBASF and Essentium have collaborated to bring to market 3D printed prosthetic sockets that promise to be more durable. Chemicals company BASF and 3D industrial solutions provider Essentium, have partnered to launch 3D printed thermoplastic carbon fiber prosthetic sockets. Clinicians can easily customize the sockets to provide an even more comfortable fit for patients. Using…

-

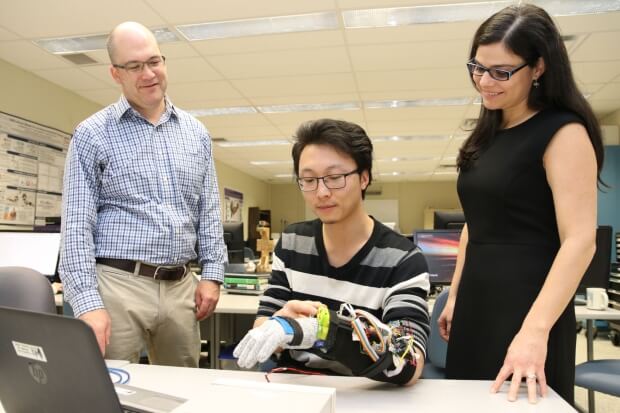

Researchers 3D Print Tremor Suppression Glove to Help Parkinson’s Patients

Reading Time: 3 minutesResearchers from Western University have developed a functional prototype of a new tremor suppression glove. This device aims to provide more independence to patients suffering from Parkinson’s Disease. Across the world, there are around 10 million people with Parkinson’s disease, a neurodegenerative disorder that causes a loss of dopaminergic neurons in the area…

-

Stratasys & Dassault Systèmes Partner to Develop Low-Cost 3D Printed Prosthetics

Reading Time: 3 minutesStratasys is partnering with Dassault Systèmes to supply Unlimited Tomorrow with 3D printing and CAD software dedicated to producing affordable, patient-specific prosthetic devices. From surgical models to personalized prosthetics, 3D printing has proven extremely advantageous for a wide variety of medical applications. Among the few pioneers of healthcare-related additive manufacturing is the 3D…