In the world of fashion, 3D printing has opened the door for a whirlwind of new looks and styles, and designers have leveraged this technology to showcase just how unique their concepts can be.

Fashion design Ganit Goldstein, a fashion design graduate from the Bezalel Academy of Arts and Design in Jerusalem, has recently unveiled a collection of 3D printed clothing and shoes.

Goldstein’s “Between the Layers” collection consists of seven outfits and six pairs of shoes, all of which were created using 3D printing. By bridging the boundaries between modern manufacturing technology and traditional fashion design, Goldstein has created a range of unique pieces. The collection is a part of Goldstein’s graduation project, fusing additive manufacturing with traditional crafts such as weaving.

“My work begins with the design and production of digital objects that serve as a three-dimensional object. […] I then weave handmade threads in a unique manner to each object,” she explained in an email.

The inspiration behind this collection arose when Goldstein visited Japan as part of an exchange program at the Tokyo University of the Arts. During her stay abroad, she had the opportunity to learn a traditional Japanese textile technique called IKAT weaving.

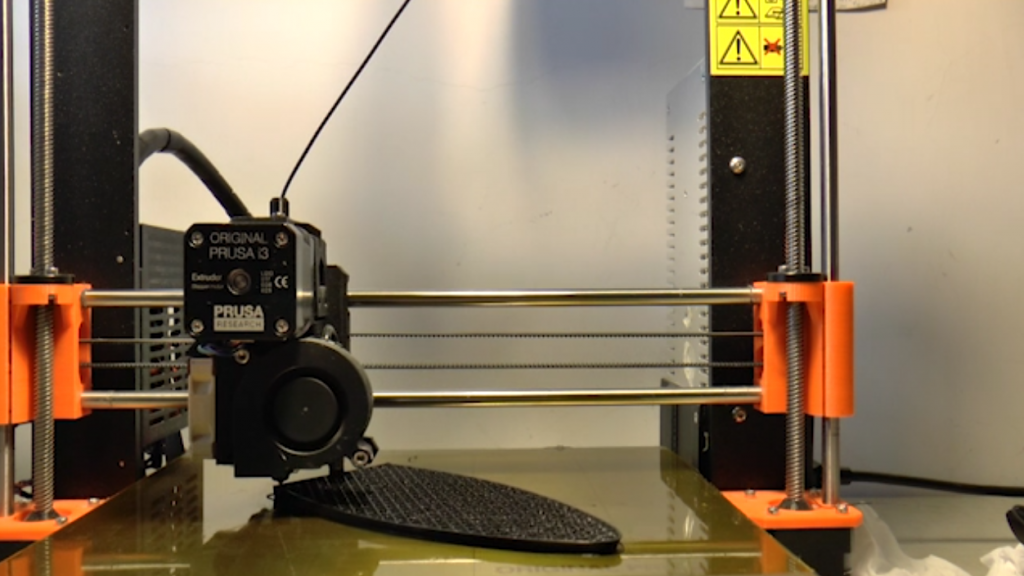

Upon her return to Israel, she began to develop a weaving process using an Orginal Prusa i3 Mk3 3D printer. She then finished off the designs by adding hand-woven layers.

Intel collaboration highlights process behind the designs

Goldstein also worked in collaboration with the tech giant Intel, using the company’s 3D scanning technology as a part of the project. Specifically speaking, she developed an Augmented Reality app that showcases the process behind his 3D printed shoes and clothing.

One of the shoes in the collection was produced with the Stratasys Connex 3 printer. The latter provides multi-color printing capabilities.

“My work begins by examining the characteristics of the material, the qualities with which I can work with,” she explained. “Working with 3D software gives me the freedom to test which boundaries can be broken. [It provides] the understanding that the connection to the traditional craft material will create a completely new essence to the original material. For example, the technique of 3D layer printing allows me to re-examine which layers can be added and what new connections I can create.”

Overall, the final collection accomplishes an interesting balance between modern technologies and traditional fashion design.

Source: Ganit Goldstein

Website: LINK