In this project, we’ll make a pair of NFC data cufflinks, ideal for storing a website URL, a password, or a secret message. This project is perfect for a sartorial spy who loves dry Martinis, and anyone who can’t remember their WiFi password.

NFC technology

NFC stands for near-field communication, and is a protocol that allows two devices to communicate wirelessly when they are physically near each other. An evolution of RFID, NFC is becoming increasingly popular in consumer technology, and is already commonly used in contactless payment systems and identification badges. NFC wristbands are also being used to create enhanced experiences for visitors at theme parks and other venues.

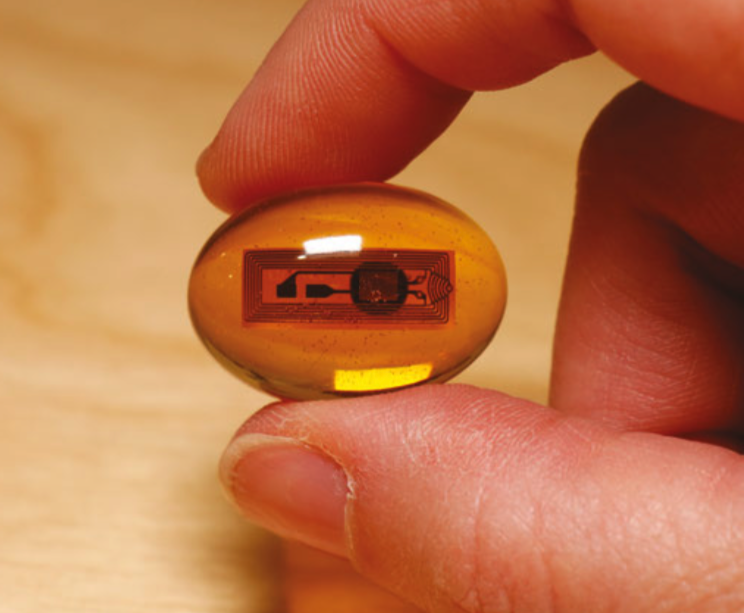

The rise of NFC hasn’t bypassed hobbyists and tinkerers, and companies like Pimoroni and Adafruit sell components that make it relatively easy to add NFC functionality to your projects. Here, we’ll make use of tiny NFC tags that can be read and written to by a smartphone or external NFC reader. The tags can be read through a non-metal barrier, like plastic, so we’ll embed the tag in resin to make an elegant cabochon for our cufflink. When complete, holding the cufflink to your smartphone or NFC reader will let you read or write data to the chip inside.

Micro NFC/RFID transponders

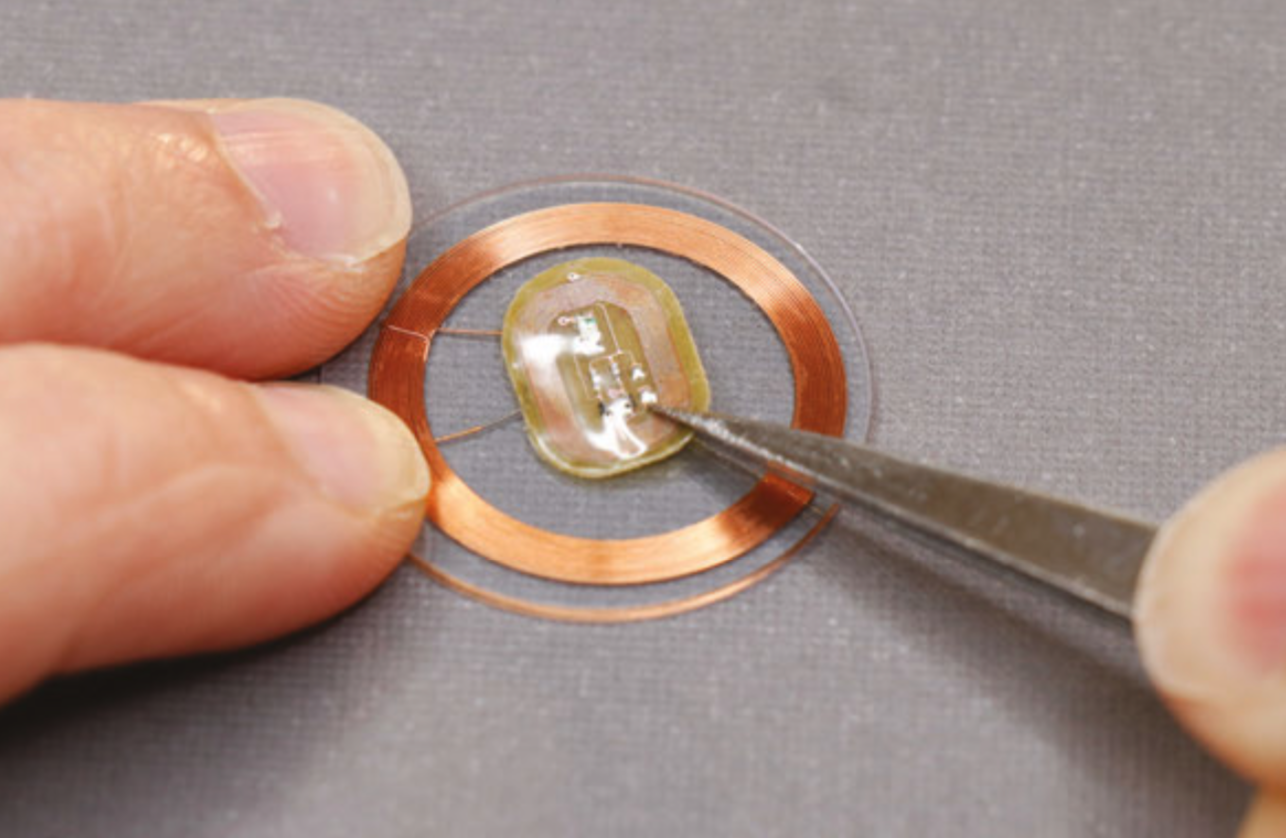

For this project we used the smallest NFC tags we could find, micro NFC/RFID transponders from Adafruit (product number 2800). These 15.6mm x 6mm flexible tags are formatted with the now standard NDEF format, and will work as-is with newer phones and most NFC readers. If you happen to pick up older Mifare Classic formatted tags, they may need to be reformatted as NDEF to work with your reader/writer. Reformatting isn’t a function of most NFC read/write apps, but it can be done with Adafruit’s PN532 NFC/RFID controller breakout board or shield.

If this is your first time working with resin epoxy, get ready for a new, fun kind of mess! Resin epoxy comes in two parts that must be mixed together in equal proportions before use. Once mixed, the resin will be workable for a short period of time before entering the curing phase and hardening completely. Figuring out exactly how much resin to mix up is definitely an art. There are even some online tools available to help calculate this. For a small project like this, just make sure you mix up a bit more than you think you’ll need.

You don’t want to run out during the pour and have to quickly mix up more at the last minute. If you’re tinting your resin, you definitely want to pour all of your pieces from the same mix, as it’s almost impossible to match the colour of one batch of resin to another.

All of this means you’ll undoubtedly end up with more than just two cabochons for one pair of cufflinks, and if you’re going to make a mess anyway, why not go big? Pick up a few extra NFC tags and plan to pour some other pieces, like pendants or key chain fobs. These make great holiday or birthday gifts that are both technologically advanced and crafty at the same time!

Resin-cast jewellery has been made for decades and there are loads of options for resin moulds available at craft stores and online. The best moulds for resin are made of silicone. Flexible silicone moulds make it easy to remove the hardened pieces, and produce ultra-shiny surfaces. Cufflink blanks, ring blanks, and pendant bails can also be purchased at jewellery supply stores. Refer to your moulds when choosing cufflink and ring blanks, to make sure that the blanks will work with the size of cabochon you’ve chosen to cast, and vice versa.

Licence to spill

Start by gathering your materials and setting up your workspace for working with resin. There will be a lot of stirring, pouring, and drips, and things are likely to get messy! Cover your work surface with paper and keep some paper towels nearby. Read and heed the safety warnings on your resin and hardener. Although some resins are considered non-toxic when used as directed, it’s always a good idea to work in a well-ventilated area and wear nitrile gloves to keep the resin off of your skin while working.

Once the two-part resin is mixed together, you will have a limited amount of time to pour the resin before it hardens, so planning and timing is key. Check the ‘pot life’ indicated on your resin; this is the amount of working time you’ll have after mixing before the resin begins to harden. Our resin had a pot life of 30 minutes. It can be helpful to set up a timer so you can keep track of time while you work.

If you have multiple moulds, decide which ones you will use before mixing, and make sure your NFC tags will fit into the shapes you plan to use. If you are making matching cufflinks, remember that you’ll need two identical shapes. Our tiny 15.6mm tags fit perfectly into 16mm cabochons. Remember that you will mix more resin than you need for just two cufflink cabochons, so it’s good to have extra moulds in front of you to pour into.

Prepare the NFC tags

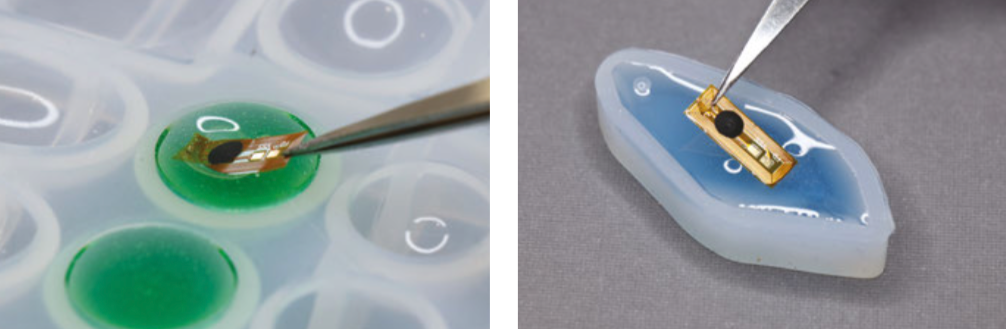

Unwrap the NFC tags and make sure they are clean and ready to be embedded in the resin. For a light-up effect, you may want to combine a data tag with an LED tag, like we did in one of our extra pieces. The back of the NFC LED nail sticker is adhesive, so it was easy to stick it directly to the larger data tag.

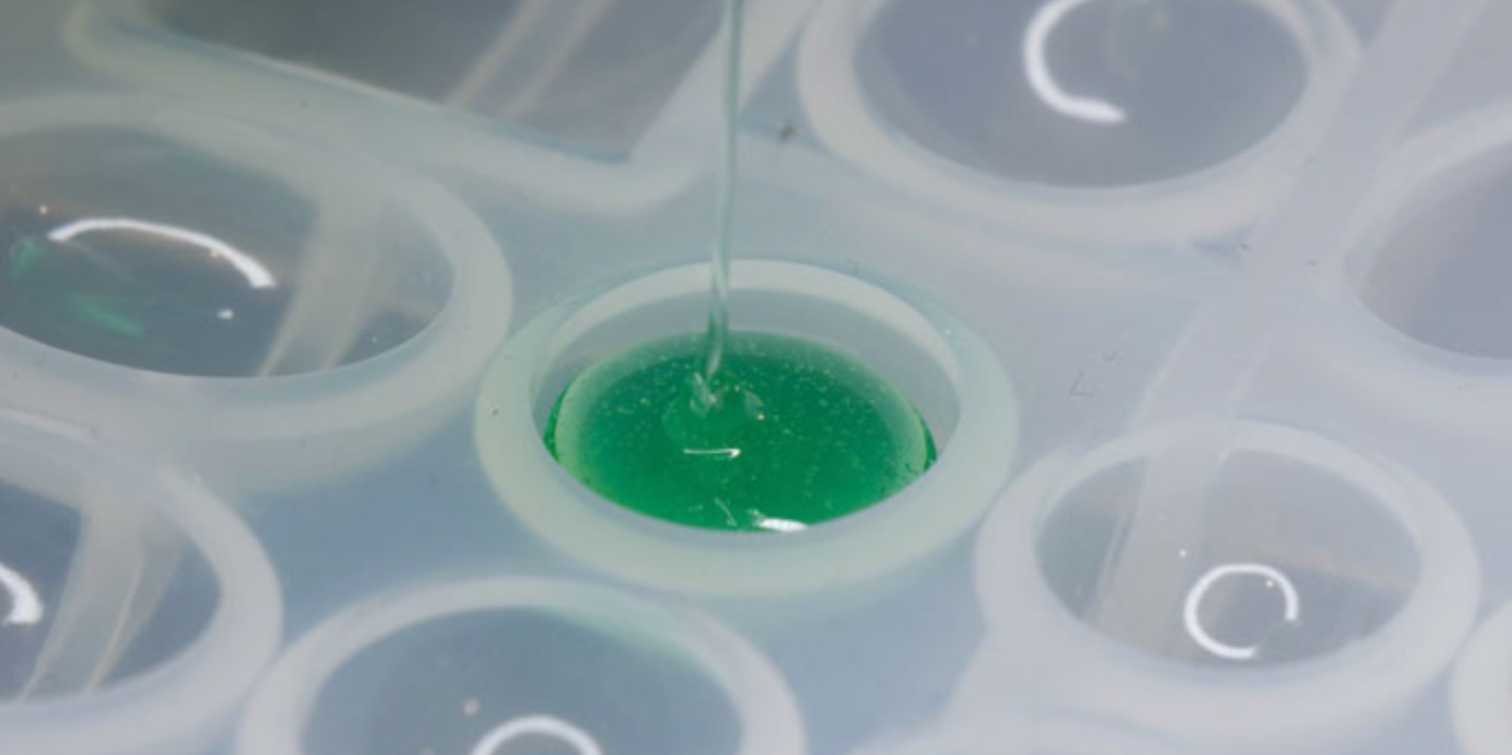

Measure, mix, and pour

We mixed up about 6oz (170g) of resin, then tinted it green for a tech-emerald look. This was plenty for two cabochons and three to four extra shapes. Follow the manufacturer’s instructions to mix up your resin. Generally, it’s a 1:1 ratio by volume. A good method for this is to pour each part into matching containers, up to the same measuring mark. Then, pour both into a third cup and stir. Stir slowly, but thoroughly, for at least two or three minutes, making sure to scrape the sides of your mixing cup often. If the resin is not completely and evenly mixed, it will not cure properly. If tinting your resin, add the tint to your mixed resin one drop at a time, slowly deepening the colour to your preference.

Once your resin is mixed and tinted, you’ll notice lots of tiny bubbles that have been incorporated while you were stirring. Let the mixture rest for a few minutes so the bubbles can float to the top, then use a stick to move the bubbles to the side of your container and pop them.

When you’ve removed as many bubbles as possible, it’s time to pour! Place your moulds on a level surface where they’ll be able to sit undisturbed for the amount of time required to cure (check the manufacturer’s instructions; ours specified 24 hours curing time). Pour the resin in a thin stream into the deepest point of your mould, and let it slowly rise to just below the top lip of your mould. Don’t overfill the mould, or the resin will bow and have a convex bottom when you remove it from the mould. Pouring the resin in a thin stream can help pop larger bubbles that are still in the mix.

Embed the NFC tag

With the resin in your mould, you can slide the NFC tag into place. Using tweezers, dip the tag into your unpoured resin to coat it first – this will help the resin in your mould accept the tag without adding too many bubbles. Then, gently slide the tag into the mould and centre it in the resin. It will want to slowly sink to the bottom of the mould, and ideally it stays centred on the way down. You may need to wiggle it back into place with your tweezers or a thin stick, but try not to introduce any new bubbles.

After your resin is poured and the NFC tags are in place, let the resin sit in the moulds for about ten minutes. This is enough time for most of the bubbles to rise to the top surface. Then, spray a fine mist of isopropyl alcohol over the resin to pop the bubbles. This step is optional, but we noticed that it really helped achieve clearer results.

Repeat this process for all the moulds you want to pour and add NFC tags to. Check them after a few minutes to make sure your tag hasn’t slid out of place, and remember to keep an eye on your pot life timer. Finish all your fiddling and bubble popping before the resin starts to harden. Then, leave your resin to cure for the amount of time specified in your resin’s instructions.

Demould your resin pieces

When the resin has completely hardened, it’s time for the exciting part: removing the cured resin from the moulds. If using silicone moulds, your piece should release from the mould without much fuss. Gently flex the silicone to let air seep between the hardened resin and the wall of the mould. Then you should be able to carefully pull the resin piece out of the mould.

Take a moment to admire your shiny cabochons! If you discover that you’ve over-poured your moulds, or the resin has crept up the sides of the mould, making a curved back, don’t worry. Resin can be wet-sanded; just be sure to keep both the sandpaper and the piece underwater while sanding, and wear a mask to keep from inhaling resin particles.

Make the cufflinks

Use glue to affix the flat-backed cabochons to the cufflink blanks. We used E6000, which is an industrial-strength adhesive that works great on plastics. Again, be sure to work in a well-ventilated area, and wear a respirator while working with E6000.

Apply the glue to the cufflink blank and hold the cabochon in place while the glue sets. Make two, and you’re done! You could also glue the cabochons to ring blanks to make NFC data rings. For pendants, you can use jewellery findings like bails and jump rings to make necklaces or key-chain fobs.

Program the NFC tag

Now that you’ve made your NFC cufflinks, you can load them with data like a website, a password, or a secret message. There are a few methods for doing this. If you have an NFC-capable smartphone, such as an Android phone, you won’t need any additional hardware. You can download a free app like NFC Tools to write and read data on your cufflink. NFC Tasks, another free app, lets you create automatic actions for your phone to perform when the NFC tag is read.

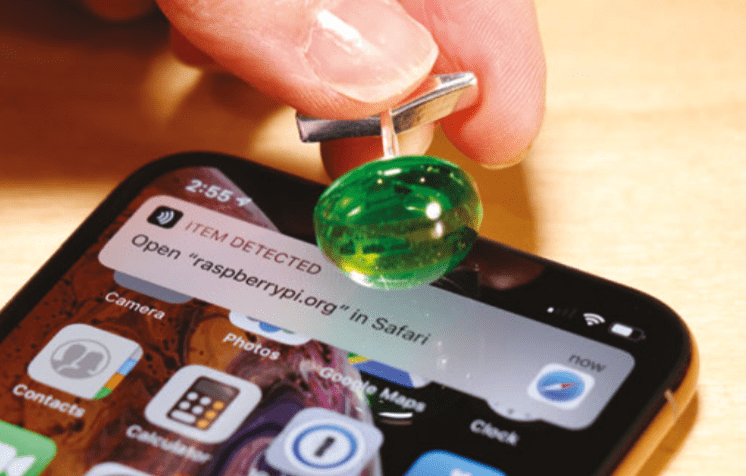

If you have an iPhone, (at the time of publishing of this article) you cannot write directly to NFC tags from your phone. But don’t worry! You can still join the NFC fun by purchasing a USB NFC reader/writer. You’ll be able to read and write to NFC tags with your computer using the NFC Tools desktop app. Your author purchased the NFC reader/writer shown here for about $35 on Amazon.com. You can still use NFC Tools on your iPhone to read tags, and the latest version of iOS, 12.1, supports background NFC tag reading. Some basic actions, like opening a URL in a browser, can now be performed right from the home screen or lock screen – pretty cool!

For a more custom hardware/software approach, try Adafruit’s PN532 NFC/RFID controller breakout board, which lets you add NFC functionality to Raspberry Pi or Arduino projects. It takes some soldering and programming to set up, but this breakout gives you lower-level control of the NFC tag, and is supported by an Adafruit NFC Arduino library. The library includes handy example code for reading and writing to tags, and reformatting Mifare Classic tags with the NDEF format.

Sport your new cufflinks at your next dressy event, and you’ll be both covert and classy! Or, gift these to your favourite snappy dresser, loaded with a secret message for their eyes only. Heading to a conference? Instead of handing out a business card to connect with someone, hold your wrist over their smartphone to bring up your webpage. It’s not magic, it’s technology!

More wearable tech projects

You can find more tutorials like this in Wearable Tech Projects by Sophy Wong, a HackSpace magazine publication. Wearable Tech Projects is on sale now from the Raspberry Pi Press online store, and it’s available as part of the Raspberry Pi Store Black Friday sale this weekend.

Website: LINK