A combination of two different PDMS polymers allows for 3D printing of complex geometries with better mechanical characteristics and better biological adhesion, according to new research from Penn State University.

PDMS (polydimethylsiloxane, or silicone) is used to make lab-on-a-chip devices, organ-on-a-chip devices, two- and three-dimensional cell culture platforms, and biological machines.

The material is more commonly seen as heat-resistant silicone spatulas and flexible baking pans, but these are geometrically simple and can easily be molded. If the material is used for growing tissue cultures or testing, the geometries become much smaller and more complex.

“So far, PDMS has limitations in formability and manufacturing of devices,” says Ibrahim T. Ozbolat, associate professor of engineering science and mechanics and bioengineering at Penn State.

“Most research is done using casting or micro molding, but this fabrication yields materials with weak mechanical properties and also weak cell adhesion. Researchers often use extracellular proteins like fibronectin to make cells adhere,” he explains.

For any material to work in a conventional 3D printer, it must be able to go through the printing nozzle and maintain shape once it is deposited. The material cannot spread, seep or flatten, or the integrity of the design is lost.

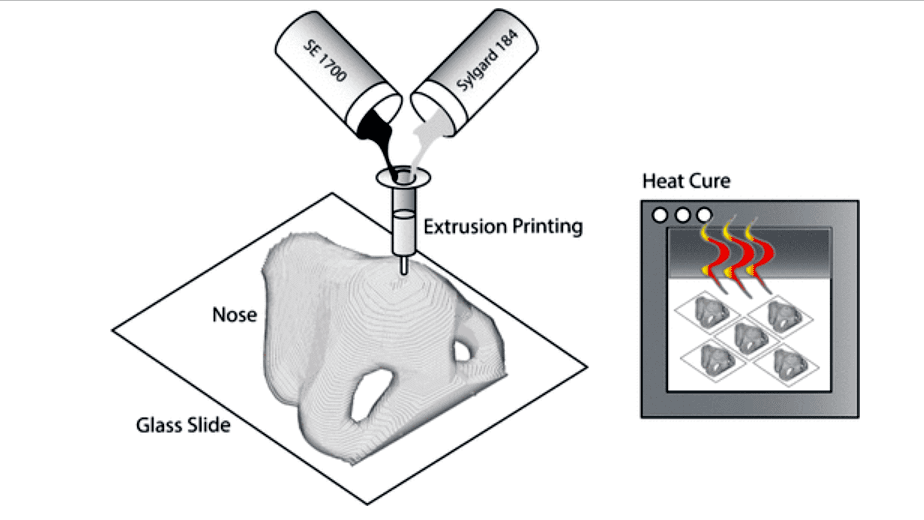

Sylgard 184, an elastomer of PDMS, is not viscous enough to use in 3D printing — the material simply flows out of the nozzle and puddles. However, when it is mixed with SE 1700, another PDMS elastomer, in the proper ratio, the mixture becomes printable.

The researchers optimized the mixture to take advantage of a materials property called “shear thinning.” They report their results in this month’s issue of ACS Biomaterials Science & Engineering.

Sniffing Out a New Use for PDMS Polymer

While most materials become more viscous under pressure, some materials have the opposite reaction and become less viscous. This is perfect for 3D printing because a fluid that is viscous enough to sit in the nozzle then becomes less viscous when the pressure of pushing out the “ink” occurs. As soon as the material leaves the nozzle, it regains its viscosity and the fine threads placed on the object retain their shape.

PDMS, when molded, has a smooth surface. The material is also hydrophobic, meaning it does not like water. Add those two properties together and the molded surface of PDMS is not an easy place for tissue cells to adhere. Researchers frequently use coatings to increase cell adherence. 3D printed surfaces, because they are made up of thousands of tiny strands of PDMS, have minute crevices that offer cells a place to stick.

To test the fidelity of 3D printing with PDMS polymer, the researchers obtained patterns for biological features — hands, noses, blood vessels, ears, and femoral head, from the National Institutes of Health 3D Print Exchange. Using these patterns they 3D printed a nose. Organs like this can be printed without support materials and include hollow cavities and complex geometries.

“We coated the PDMS nose with water and imaged it in an MRI machine,” said Ozbolat. “We compared the 3D reconstructed nose image to the original pattern and found that we had pretty decent shape fidelity.”

Because the PDMS materials are being printed, they could be incorporated with other materials to make one-piece devices composed of multiple materials. They could also incorporate conductive materials to enable functionalized devices.

Source: Penn State

Website: LINK