When I wasn’t reading books or playing adventure games, I was learning BASIC and making my own creations. Computing classes covered everything from acid-etched circuits to PASCAL programming.

As I worked my way through school, the computer became less about exploring the potential of a wonderful new gizmo and more about fitting students into the mould of office life. By the time I went to college, I was being taught touch-typing and how to format word-processing documents.

My love of narrative was filled with English and art, and computing became a personal hobby and less of an academic study. This is a shame because computers are incredible things. Packed with unlocked potential that can be used in all kinds of scientific and creative endeavours. Without computers, we wouldn’t have modern art in its current form; or video, film, or modern music. Still, I managed to bring it all together by editing a magazine about computers and taking courses at MITx.

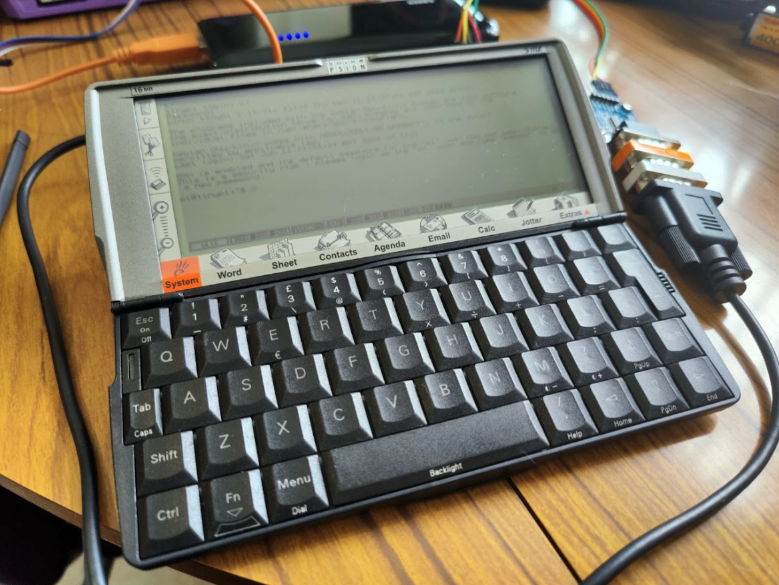

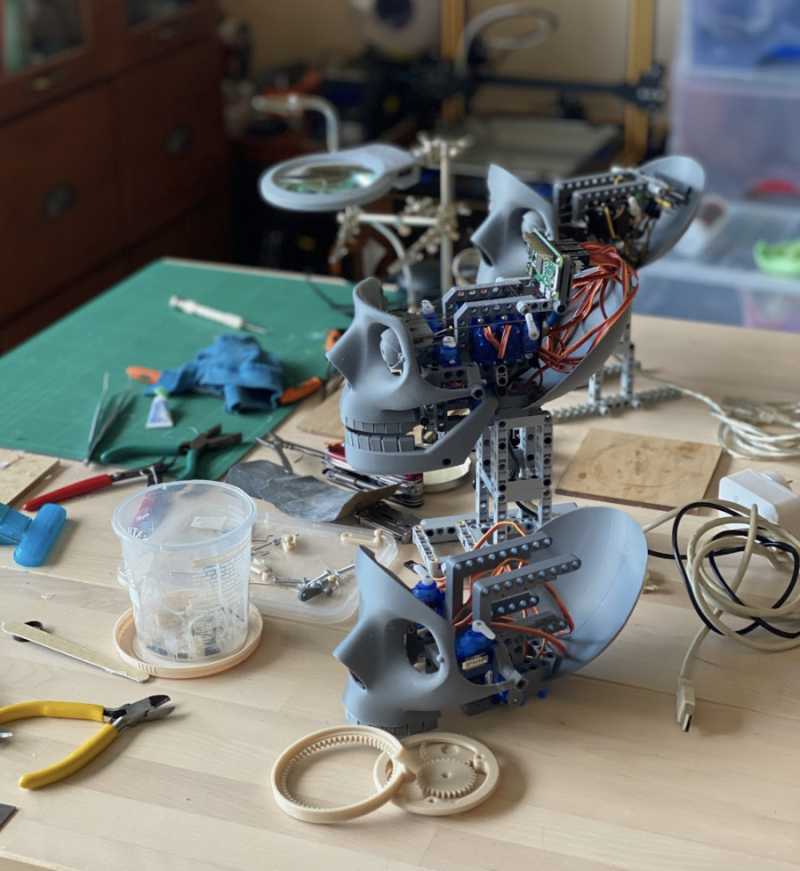

It’s no surprise to me that some of the most creative people I’ve ever met are quite nerdy; and vice versa. The secretarial training was the opposite of both: learning by rote with no understanding. It was bland. In retrospect, I should have taken the electronic typewriter apart to see what was going on inside.

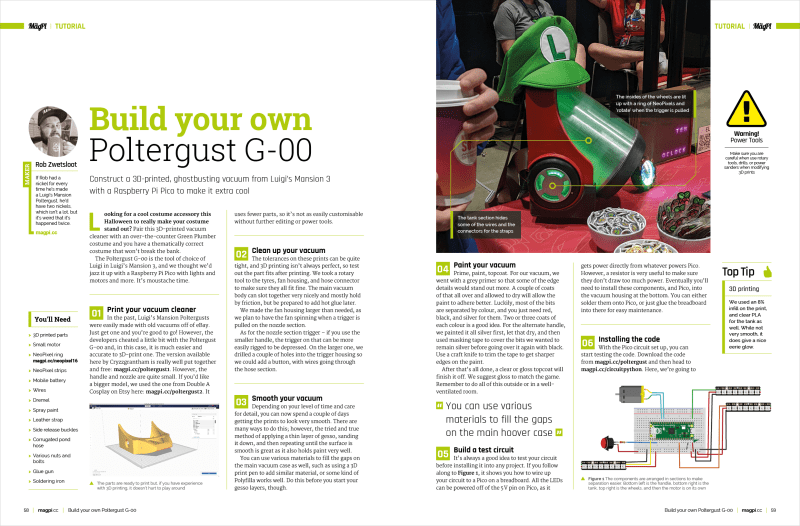

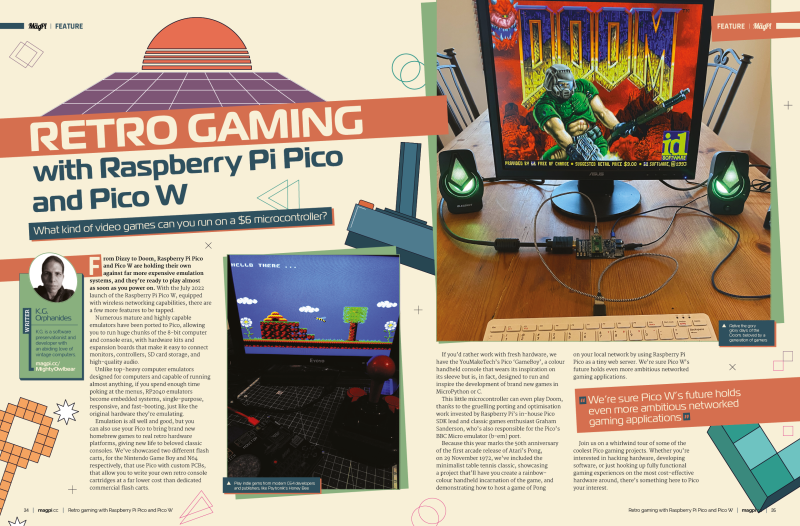

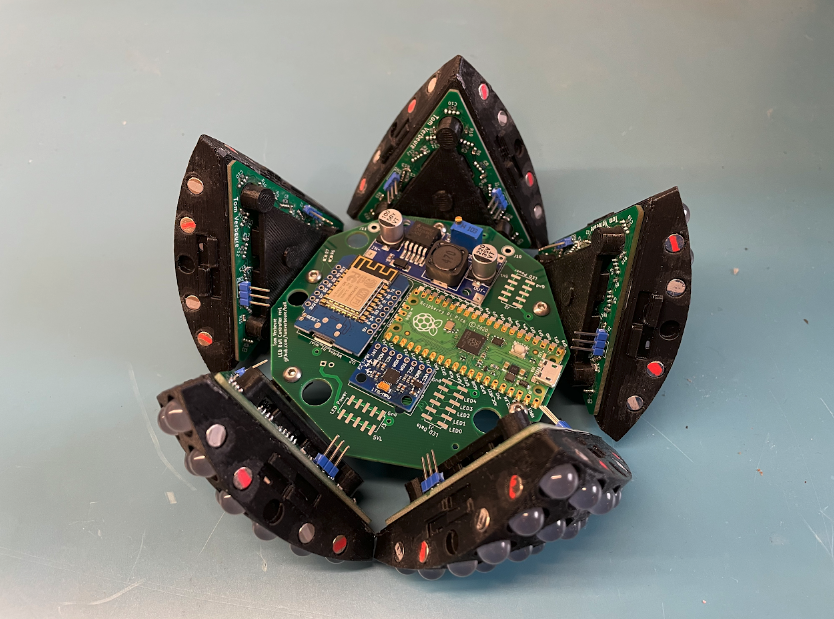

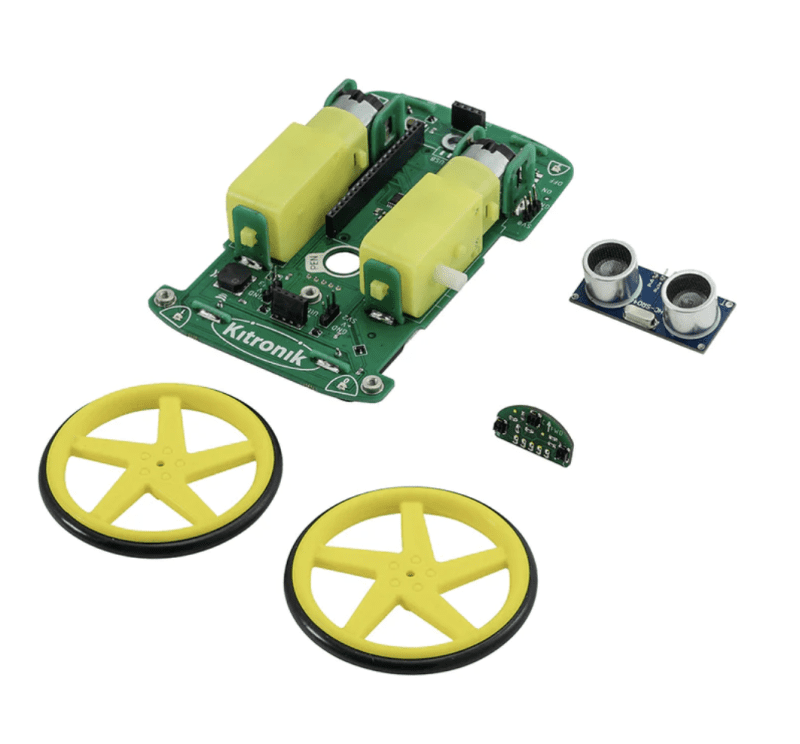

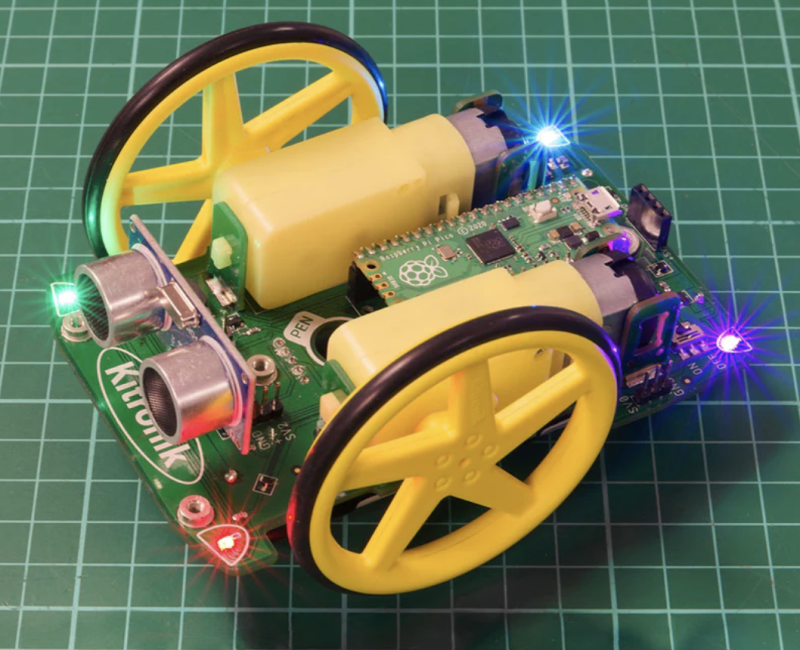

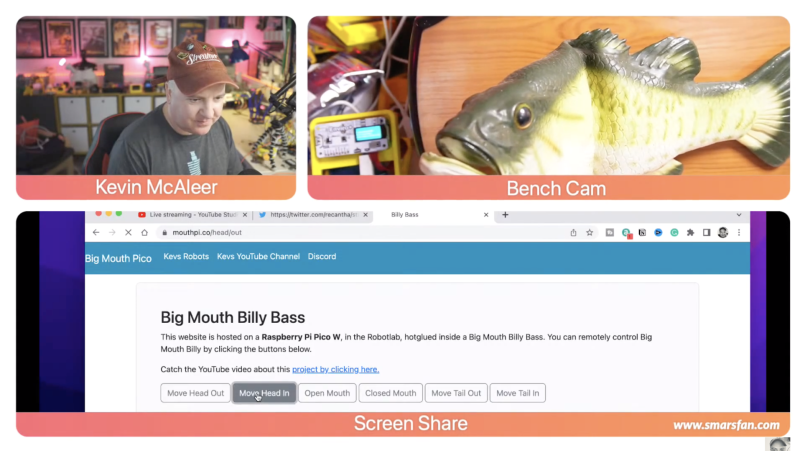

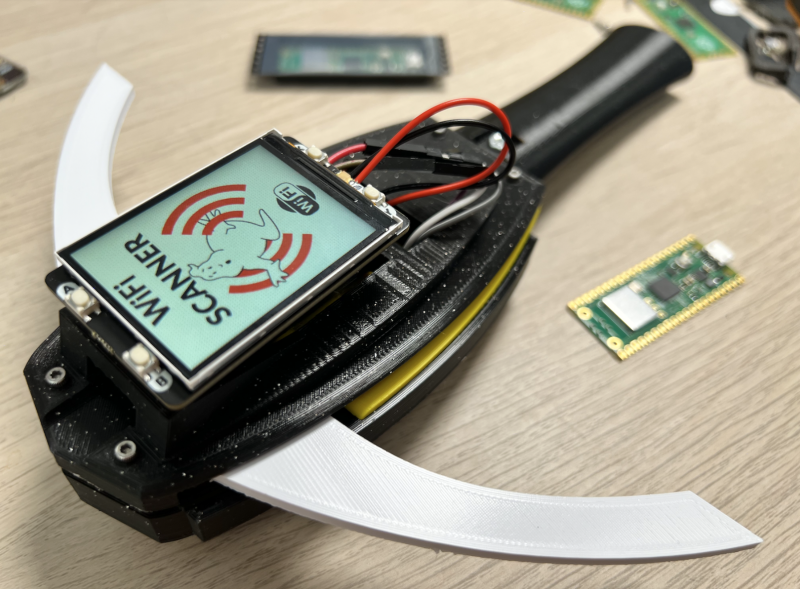

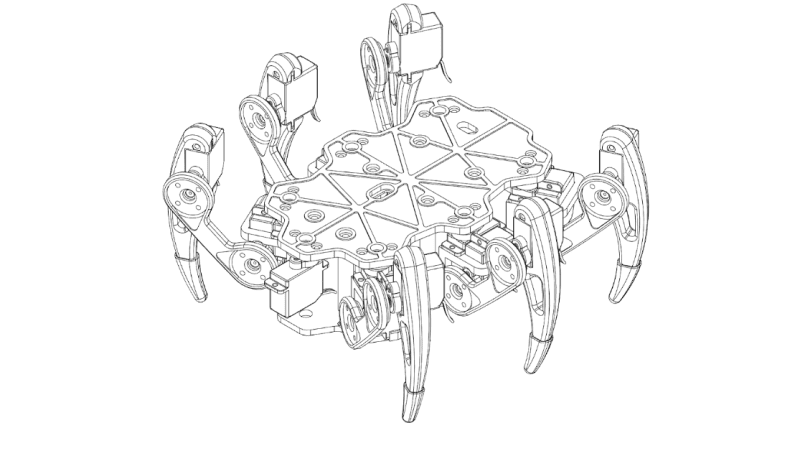

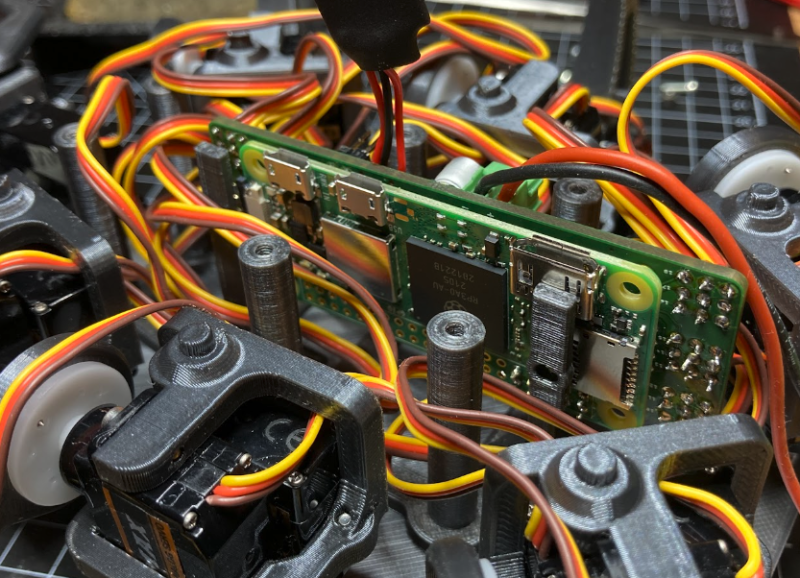

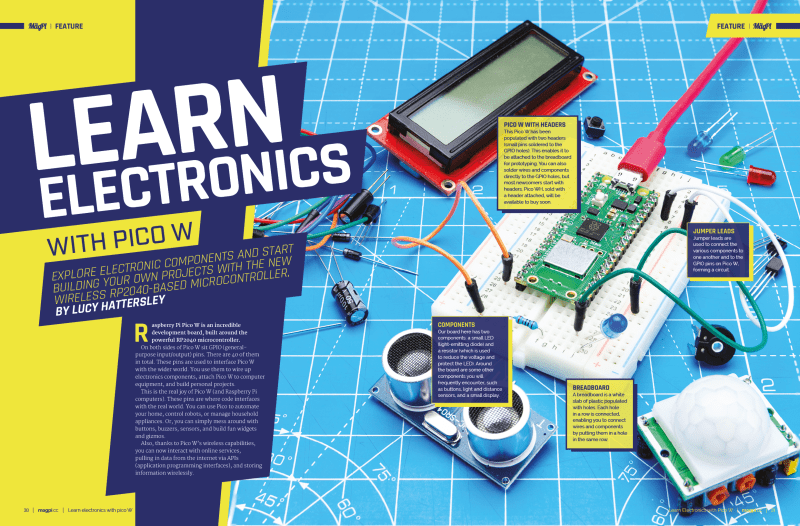

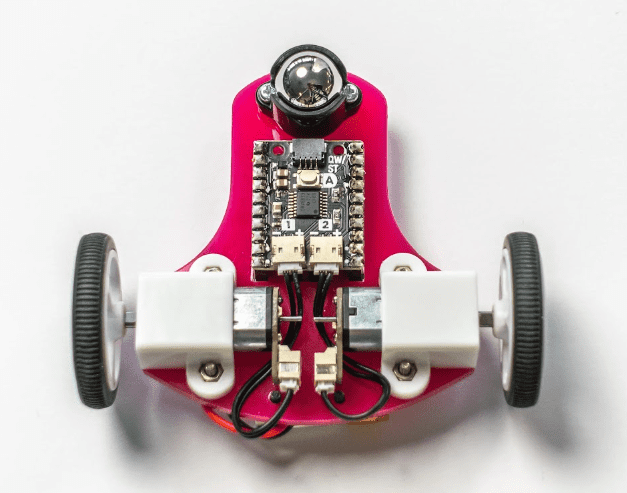

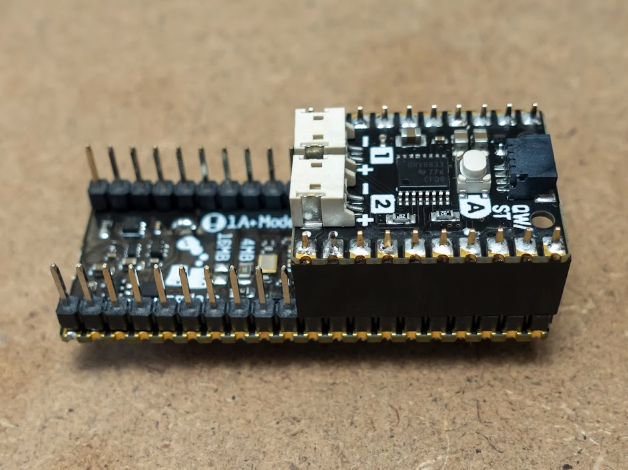

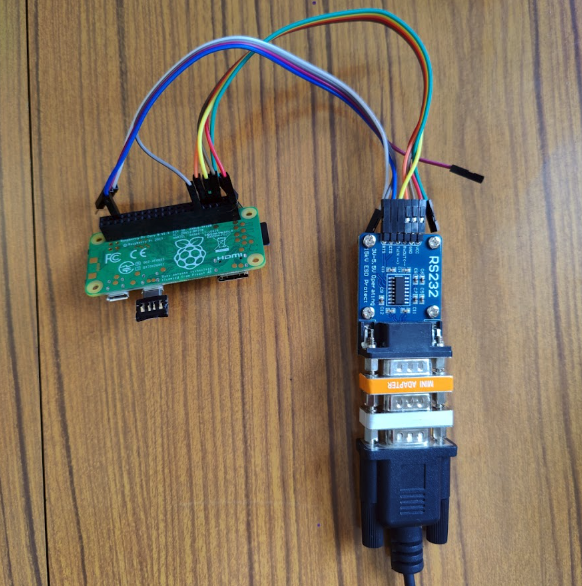

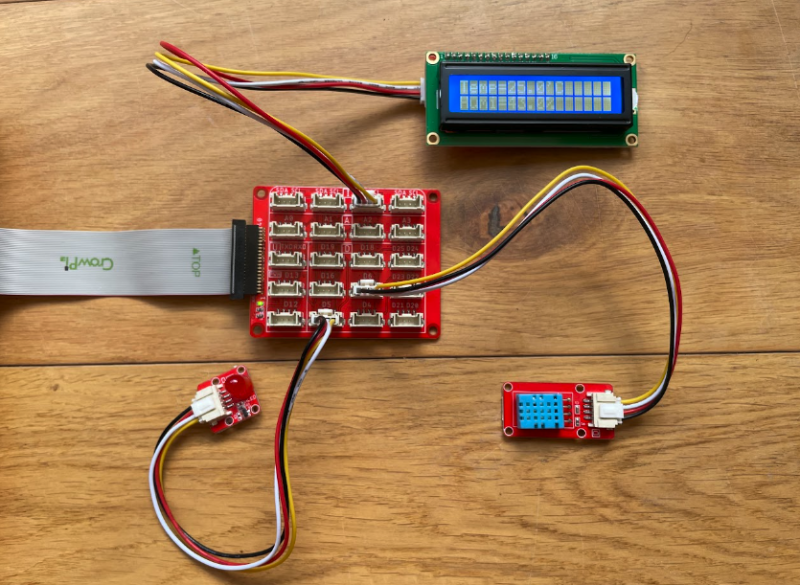

I like to think that Raspberry Pi and the new Pico microcontrollers can fill the tech void that is teaching, otherwise smart kids, basic office skills to tick government check boxes. Simply putting bare tech in front of kids who are interested can make all the difference.

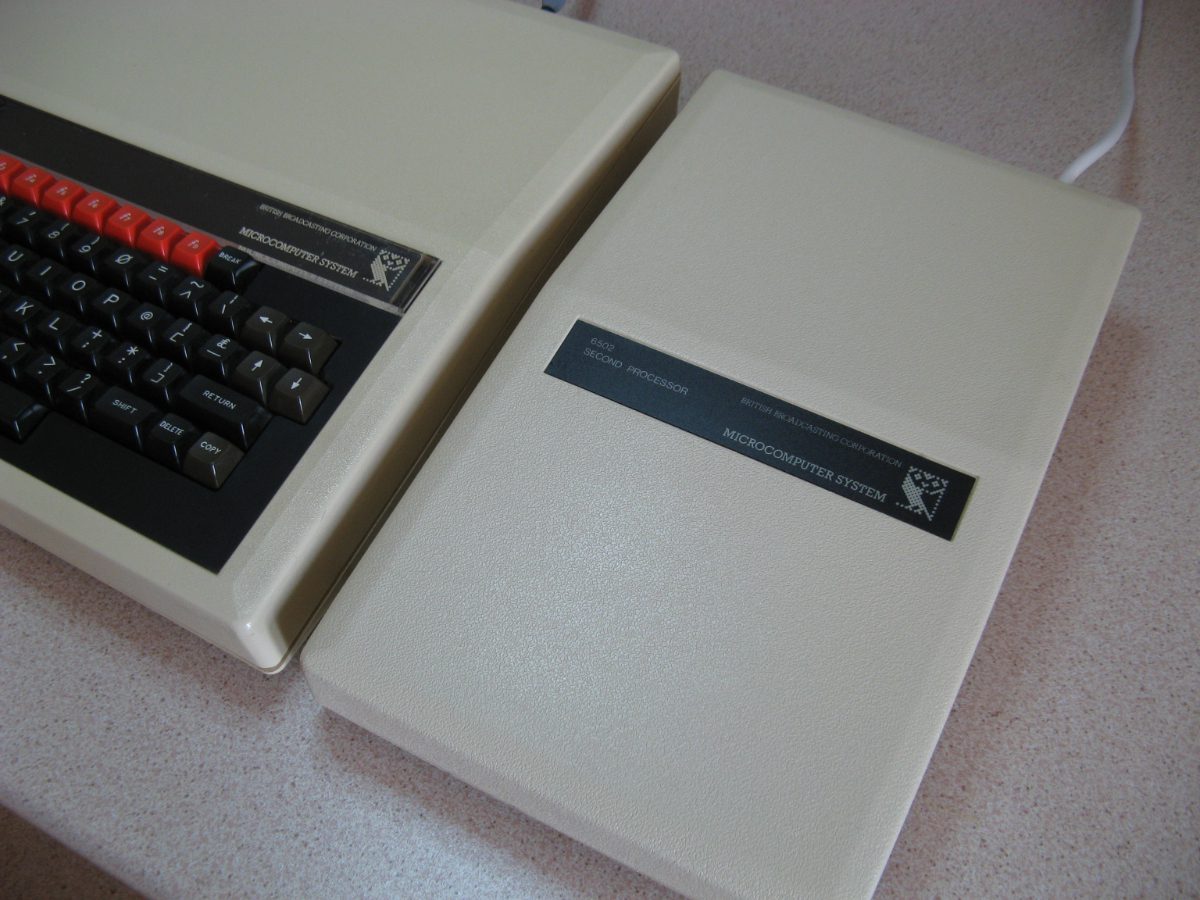

Our retro gaming with Pico feature obviously appeals to retro geeks like me who remember the 8-bit days with love and affection. I learnt coding and computing by experimentation. Retro computing on a modern device, like Pico, also shows how cutting-edge technology can trace a path back to earlier days and help us gain an understanding of computing development.